Prior to mounting the fan:

• Read the present User’s manual carefully.

• Check the fan for any mechanical damages caused by wrong transportation.

• Manually check the impeller for smooth rotation.

• Make sure there is no condensate on the motor

• Check the electrical resistance of insulation between the motor windings and between each winding and the motor casing

Follow the safety regulations during the make-ready procedures and fan operation.

Fan mounting:

• Install the fan on the building roof, out of possible fire areas.

• Check the roof frameworks for sufficient rigidity in installation places.

• The fan is designed for vertical installation only (vertical fan shaft) on a concrete or steel base plate of min 250 mm height (with

respect to possible level of precipitation).

• Remove the side shields and fix the fan to the mounting frame with four anchor bolts at the frame corners.

• Check that the fan components do not get deformed during mounting.

• Provide free and unhampered air extraction from the fan.

The fan delivery set may include a mounting frame (available separately). Install the mounting frame on a load carrying roof section true-

vertical inside a prepared opening. The opening size must be sufficient to ensure free passage of air ducts with connecting flanges of the

corresponding diameter in accordance with the DIN 24154 Series 3.

Fix the mounting frame to the load-carrying roof surface in compliance with construction norms and standards applicable for standard

building designs.

Attach the backdraft damper or the first air duct section directly to the fan prior to its installation. The backdraft damper is delivered

separately. Provide additional fixing of the air ducts to the building structures to avoid load transfer from the air ducts to the fan.

Do not put the fan on the air duct while mounting to avoid its deformation.

Fastening the fan to the mounting frame is carried out with bolts and washers of the appropriate size.

After installing the unit, you need to make sure that the fan impeller rotates freely.

READ THE USER'S MANUAL BEFORE INSTALLING THE UNIT.

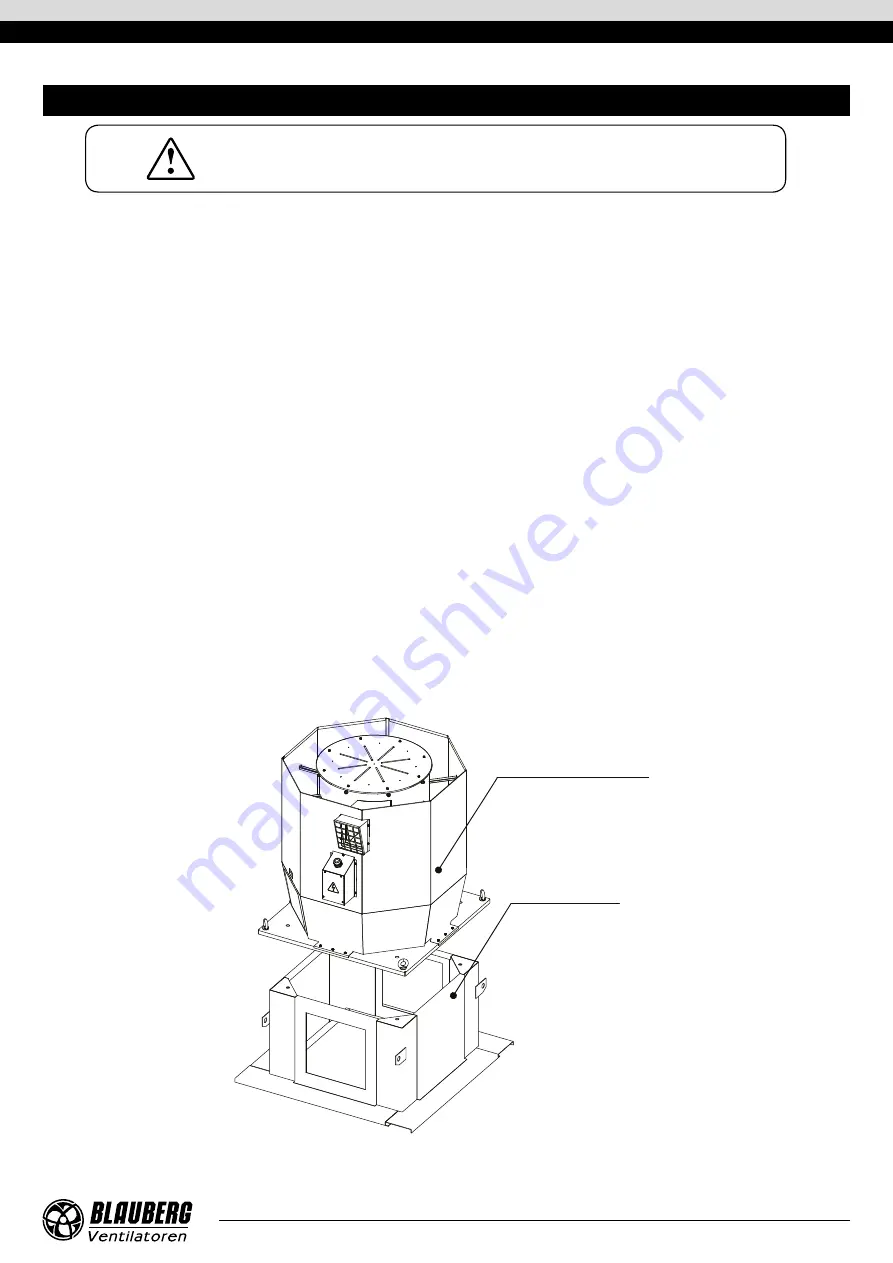

Mounting frame

Tower-SV-K2 fan

MOUNTING AND SET-UP

www.blaubergventilatoren.de

tower-sV-k2

9