12

www.blaubergventilatoren.de

KOMFORT EC LB/LBE S11

The control panel includes a lithium cell CR1220 with a limited time

resource.

The battery keeps the internal clock running while the unit is disconnected

from power supply. If the unit is disconnected from power supply and the

battery is low, the clock stops and the day and time settings are reset. This

leads to incorrect date and time indication when the unit is on and, as a

result, to incorrect scheduled operation of the unit. In this case, the battery

should be replaced. To replace the battery use a new battery only.

Battery replacement:

1. Disconnect the air handling unit from power supply.

2. Remove the two screws in the casing bottom.

3. Remove the display. Replace the battery as shown.

4. Assemble the control panel in the reverse order. If the terminal block

wires on the upper circuit board were unplugged make sure to re-connect

them correctly. Failure to re-connect the wires properly will result in operating

failure of the equipment.

5. Connect the panel to the power supply and set the current date and

time.

General description of the automatic control system.

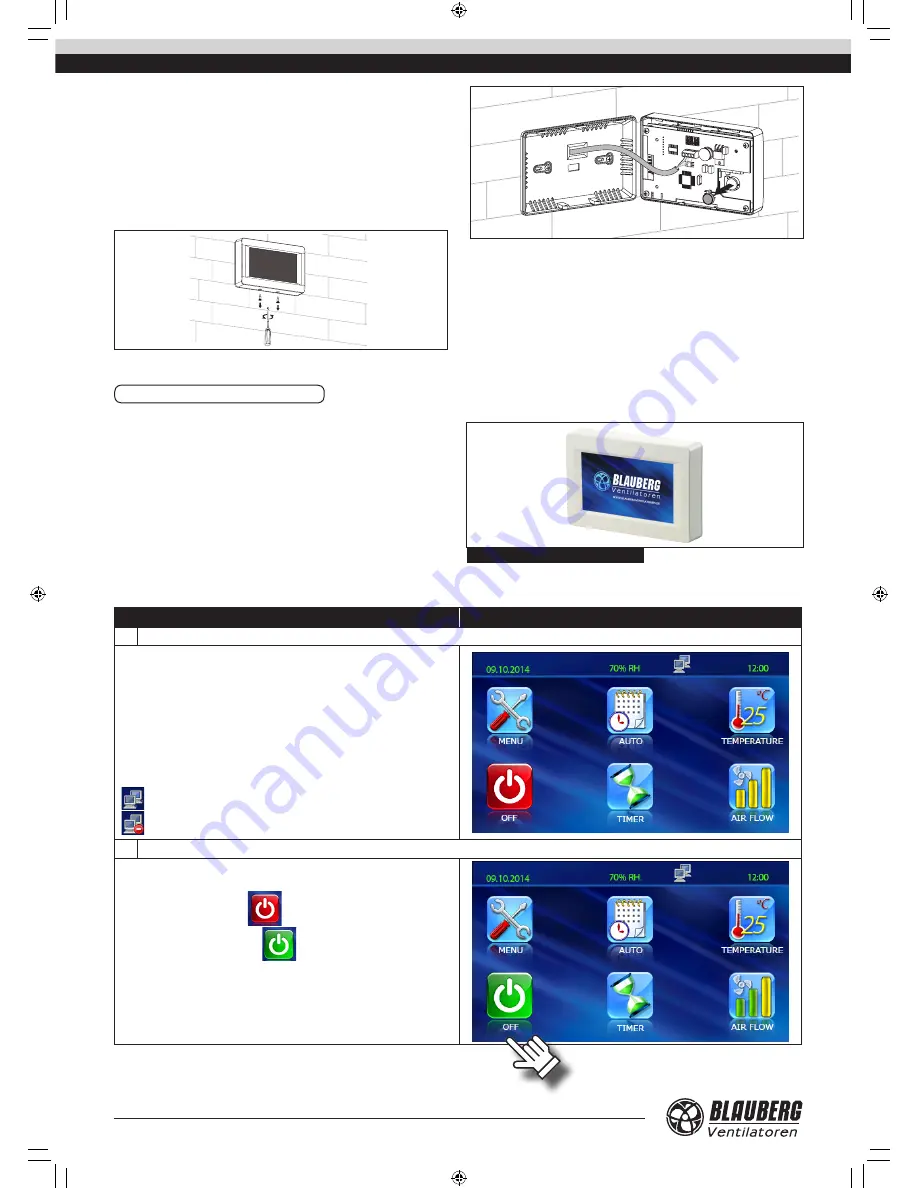

The unit is operated via the wall-mounted control panel with a sensor

display, Fig. 11.

Fig. 11. Control panel

UNIT CONTROL

Table 6. Unit control and adjustment of operating parameters of the unit

Function

Indication

1

Main menu

The Main menu contains the date, current humidity, time, temperature and

set air flow.

MENU − access to the User menu, see clause 5.

AUTO − scheduled operation activation/deactivation.

TEMPERATURE − display of the current indoor temperature. After pressing

this button the Temperature Setting menu is opened, see clause 4.

ON/OFF − turning air handling unit ON/OFF or Standby mode activation.

TIMER − turning the timer on/off.

AIR FLOW − current fan speed display. The Fan Speed Setting menu is

accessible through this button, see clause 3.

The network connection status indicator is displayed:

− the unit is connected to network.

− the unit is disconnected from network.

2

Unit activation and deactivation

The unit is activated with ON

button.

The unit is deactivated with OFF

button. During the unit

deactivation the indicator changes its colour from red to green.

In the Standby mode the unit operates at the first speed and set

temperature, see clause 12.

KOMFORT_EC_LBE_v1(3)_EN.indd 12

11.08.2015 9:01:20