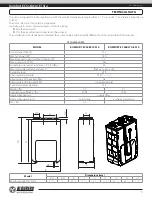

CONDENSATE DRAINAGE

Condensate drainage is required for the Komfort EC S5B270 S14 unit series. The Komfort EC S5B270-E S14 units are equipped with a heat

exchanger with an enthalpy membrane at the core. No condensate is formed in heat exchangers of this type, therefore, no condensate

drainage is required. The hole for the drain pipe connection is located at the bottom of the unit. Open the service panel, remove the heat

exchanger and filters, drill a hole (

7

/

8

inch in diameter) in a plastic pan in the exhaust air duct and install the drain pipe (supplied) in the

hole. Then connect the drain pipe to the sewage system using the SG-32 U-trap kit (purchased separately). The pipe slope downwards

must be at least 3°.

min 3°

Drain hose

U-trap

Sewage system

Drain pipe

The condensate drainage system is designed for normal operation in premises with air temperatures above 32 °F!

If the expected ambient air temperatures are below 32 °F, the condensate drainage system must be equipped with heat insulation and

pre-heating facilities.

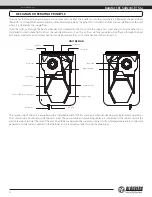

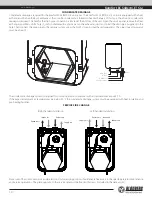

SERVICE SIDE CHANGE

Right-handed installation Left-handed installation

Intake air

Intake air

Supply air

Supply air

Extract air

Extract air

Exhaust air

Exhaust air

Make sure of the correct unit service side selection. Unit mounting position should enable free excess to the opening plate for maintenance

and service operations. The plate opposite to the service side must be fixed with screws (included in the delivery set).

www.blauberg.us

Komfort EC S5B270(-E) S14

10