4

+

-

4

+

-

4

+

-

8

SERIES

+

-

4

+

-

4

+

-

2

PARALLE

+

-

4

+

-

4

+

-

8

SERIES

+

-

4

+

-

4

+

-

2

PARALLE

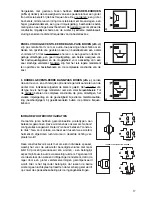

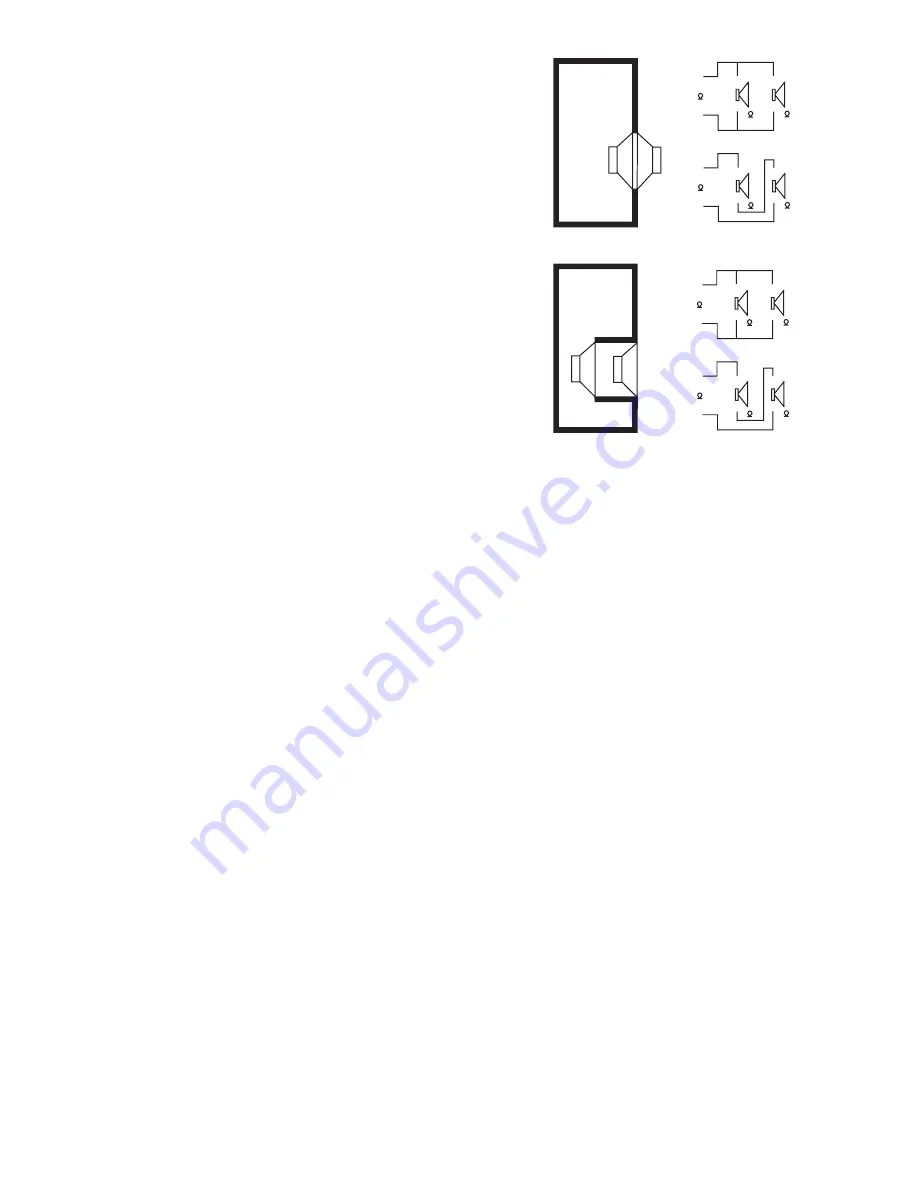

ISOBARIC CONFIGURATION (TANDEM)

ISOBARIC WOOFER CONFIGURATIONS

Increasing in popularity in recent years is the compound woofer

design, more commonly known as the “Isobaric” design. Isobar-

ic actually means “constant pressure” which is the case having

two woofers moving an encapsulated pocket of air between

them in the same direction.

This arrangement acts like a single speaker which effectively

reduces the required box volumes for a subwoofer system by

50% which is substantial if you are space-limited. Unfortunately,

the trade-off for space is the 3 dB loss in efficiency but this is

usually recovered with increased amplifier power. Care must be

taken to avoid air leaks between the two woofers and final

speaker wiring and impedance loads must be carefully

watched.

SUBWOOFER ENCLOSURE CONSTRUCTION

Before starting final box assembly some basic construction issues should be mentioned:

–

Infinite baffle construction in a car is done by simply cutting a piece of wood which will act as an

acoustical divider isolating the front and rear sound of the woofer. This piece of wood is mounted

inside the trunk of the car under the rear deck, or against the back of the rear seat, and should have

some kind of caulking to seal off all residual air leaks.

–

Box construction can take on nearly any shape since we are dealing with low frequencies. Odd

shapes that are difficult to cut and glue should be avoided.

–

Particle board, MDF, or high grade birch plywood are good materials to build boxes of thicknesses

of 19 to 25 mm.

–

All seams in the box should be glued, screwed and caulked to prevent wall separation over time

due to vibration and environmental changes within the car.

–

Cross bracing is important for large boxes to prevent wall vibration.

–

Acoustical damping material (sheep wool or fibre-glass batting 5 to 10 cm thick), attached to 50%

or more of the interior walls helps reduce box noise and also increases the box volume seen by

the woofer by 10 - 20%. The application of self-adhesive damping mats to the inside walls also

helps to eliminate wall resonances.

–

The cables running from the amplifier to the subwoofer should be as short as possible with a cable

cross section of at least 4 mm2.

–

The final box should be rock solid and air tight but should also remain serviceable should a woofer

be damaged for any reason.

–

When possible, use 10 to 15 cm diameter port tubes to avoid wind noise from smaller diameter

sizes. PVC plumbing pipe in various diameters is available at most hardware stores with „elbow“

pipes allowing you to bend the tubes inside the box.

–

Try to always use active (electronic) crossovers, such as those built into our

Velocity

amps, for

example.