OM-AF20.1 E V1.02

May 15, 2015

Page 36

AF20

.1

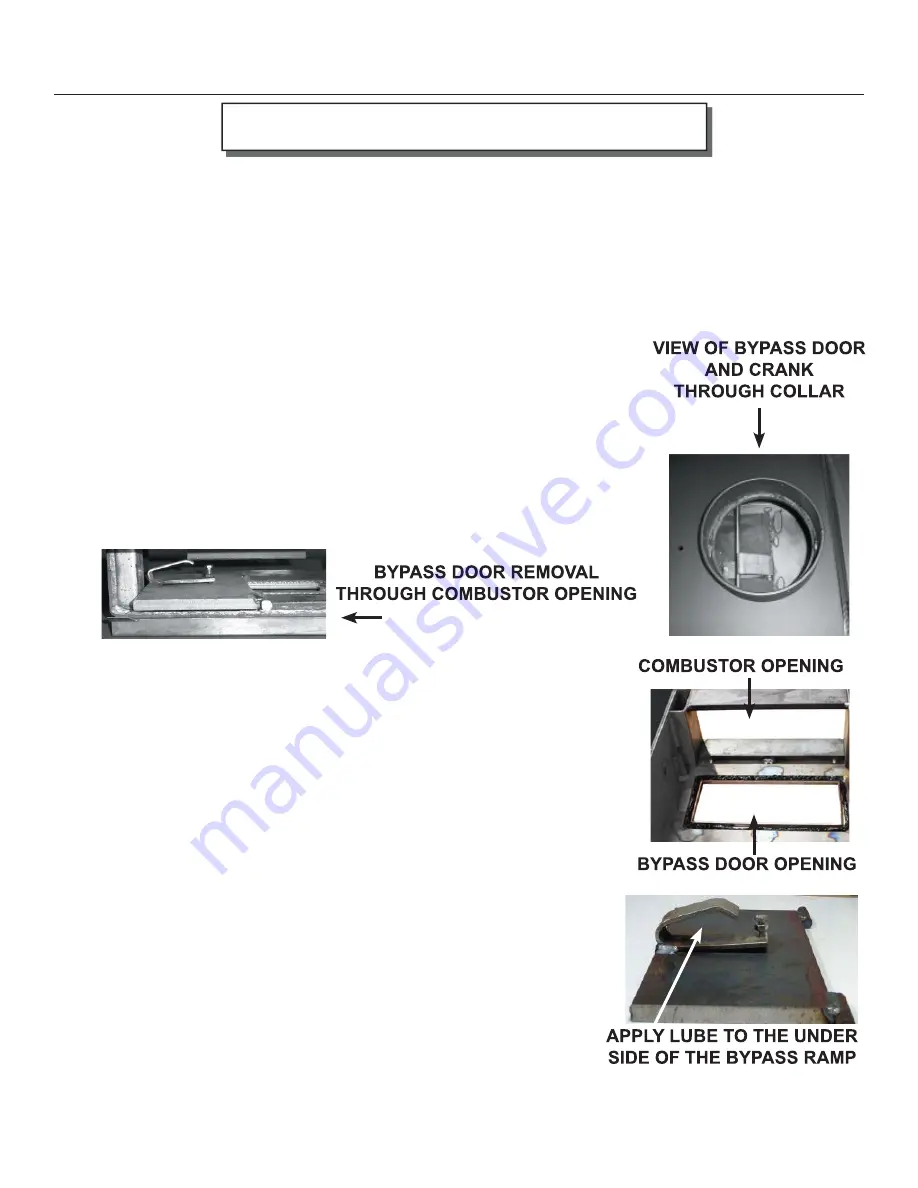

BYPASS DOOR GASKET INSPECTION

If you do not hear a positive click when closing your bypass door fi rst try adjusting the tension, see number 9

below. If the seal is not tight aft er making the adjustment, the gasket may need to be replaced.

MAINTENANCE cont.

BYPASS DOOR GASKET REPLACEMENT

BLAZE KING RECOMMENDS YOUR DEALER PERFORM THIS TASK

1. You will require THERMOSEAL® 1000SF high-temperature resistant cement and Blaze King 5/8” dense

fi ber glass gasket. See your Blaze King dealer. You will also require masking tape and combustor gasket

as disassembly of the combustor will result in a damaged combustor gasket.

2. Be sure the fi re is out and the stove has cooled down.

3. You will need to remove the liner from the collar of the stove, and have the

ability to see straight down into the stove box through the collar.

4. Please follow steps “CATALYTIC COMBUSTOR, REPLACEMENT” on

page 30 on how to remove your combustor.

5. To remove the bypass door, move the bypass rod out of the way using the

bypass handle on the side of the stove. Looking down through the collar,

lift one end of the bypass door for clearance to turn inside the top assembly.

Once the bypass plate is in this position, remove the plate through the

combustor opening.

6. Remove the old gasket and apply the THERMOSEAL® 1000SF high-

temperature resistant cement along the door opening edge.

7. Place the gasket along the cement, and tap it in to seat it securely in

the channel.

8. Reverse method of removing bypass door to put it back in place.

9. Prior to reconnecting the liner, you will need to adjust the bypass

ramp bolt. You must fi rst loosen the retaining nut located under the

head of the adjustment bolt. Th

en using a 7/16” box wrench, tighten

the bolt until the bypass handle, when closed, has a slight cam-over

feel. Do not over tighten.

10. Secure bolt adjustment by tightening the 7/16” nut against the ramp

as seen in the photo to the left . Now work the bypass handle several

times to make certain the bypass operation is smooth and working

properly. When you are satisfi ed with the operation of the bypass,

please lower the venting.

Important: Apply high temp anti-seize lubricant to the under side of

the bypass ramp where the rod contacts.

11. Please follow steps 5-8 on pages 31 & 32 to return the combustor into

place. Please note that if the gasket of the combustor is damaged, it

will have to be replaced.