8

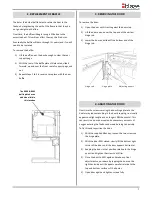

This task may be easier with the door removed from the

appliance and laid horizontally on a work-bench.

To replace the door glass:

1)

Remove the six M6 size Allen key screws securing the

glass retainer to the door with the supplied Allen key.

2)

Gently lift the glass retainer up and out, taking

careful note that the glass may still be intact in

the retainer and potentially could fall out.

3)

Flip the retainer over, remove the old glass panel.

4)

The new door glass panel should have been

supplied with a length of adhesive glass seal. Peel

back the backing on the tape, and run it along the

edges of the glass panel, folding it equally over

each side so as to create a padded border around

the edge of the glass.

5)

Fit the new glass into the glass retainer, relocate

the retainer so that all six threads can be seen

through the holes, before fastening the six

screws.

6)

Dispose of the old glass in a responsible manner.

This task may be easier with the door removed from the

appliance and laid horizontally on a work-bench.

1)

Remove any old seal from the door.

2)

Clean out the groove in the door that the seal was

bedded in using a flat-end screw driver or equivalent.

3)

Run a thin bead of clear roof and gutter silicone along

the groove.

4)

Starting at one end, press the new door seal into the

groove on the door.

5)

Refit the door if it has been removed and close.

Over time, the door seal can become compressed resulting in

a less than adequate seal between the door and the front

edge of the firebox. For example, if the wood burns unusually

fast even with the air slide shut, it may mean that there is an

air leak around the door.

In this situation, the door seal does not necessarily need

replacing rather adjustment of the door handle can tighten

the seal.

5. FITTING A NEW DOOR GLASS

6. FITTING A NEW DOOR SEAL

7. DOOR HANDLE ADJUSTMENT

Allen key screws Hinge bracket

Adhesive glass seal Glass

Glass retainer Door Rope