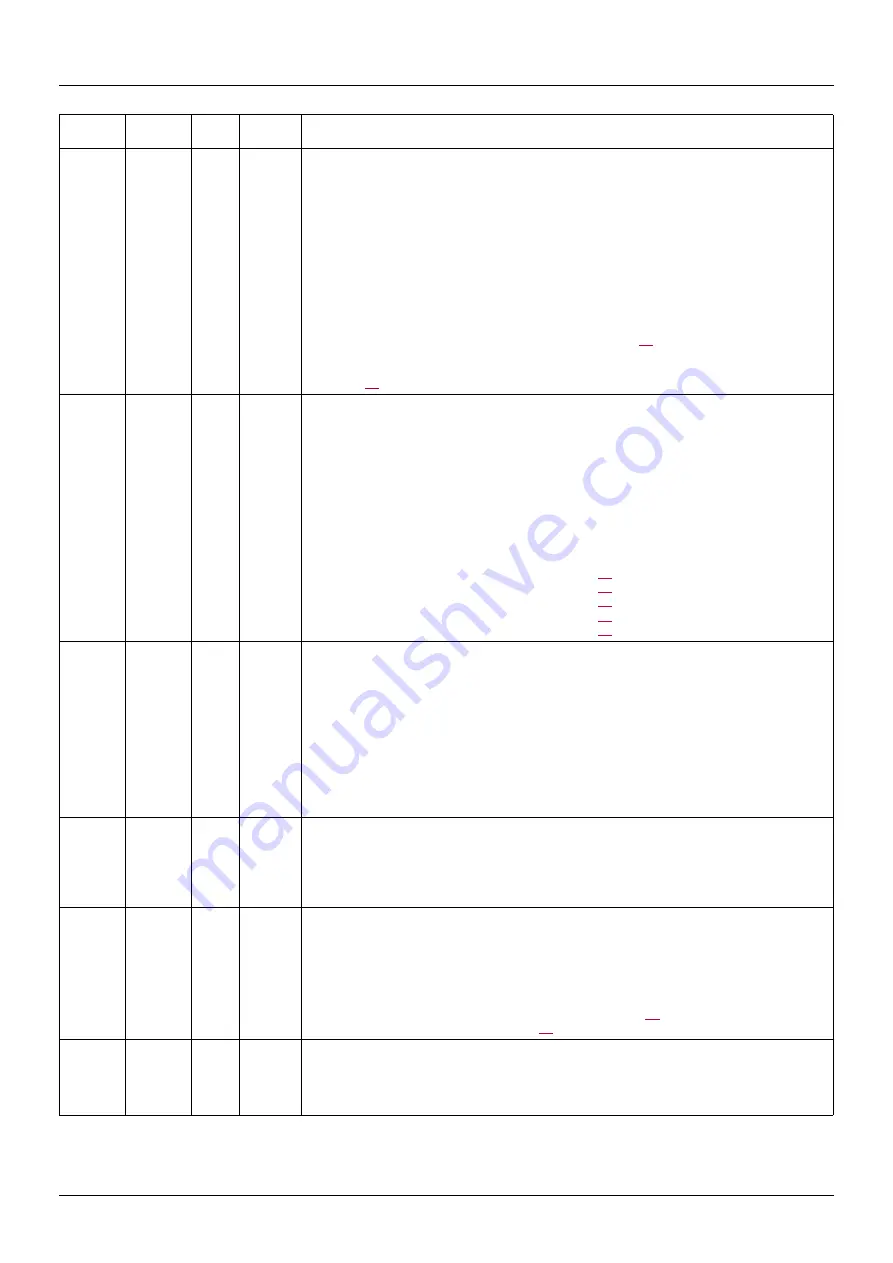

52

Configuration and adjustment variables

Modbus

address

CANopen

address

Code

Read/

Write

Name/Description/Possible values

3110

2001 / B

FLr

R/WS

Flying restart (automatic catching a spinning load on ramp)

Factory setting: 0

Used to enable a smooth restart if the run command is maintained after the following events:

- Loss of line supply or disconnection

- Reset of current detected fault or automatic restart

- Freewheel stop

The speed given by the drive resumes from the estimated speed of the motor at the time of the

restart, then follows the ramp to the reference speed.

This function requires 2-wire control (tCC = 2C) with tCt = LEL or PFO.

0 = "nO": Function inactive

1 = "YES": Function active

When the function is operational, it activates on each restart following one of the above events,

resulting in a slight delay (1 second max).

FLr is forced to nO if brake control (bLC) is assigned (page

).

Note: Do not use the flying restart function (FLr = YES) with auto-tuning on power-up (rSC or

POn page

).

7131

2029 / 20

EtF

R/WS

External fault

Factory setting: 0

0 = "nO": Not assigned

129 = "LI1": Logic input LI1

130 = "LI2": Logic input LI2

131 = "LI3": Logic input LI3

132 = "LI4": Logic input LI4

133 = "LI5": Logic input LI5

134 = "LI6": Logic input LI6

If LAC = L3 and LEt = HIG, the following assignments are possible:

171 = "Cd11": bit 11 of the CMD control word (page

) written by Modbus or CANopen

172 = "Cd12": bit 12 of the CMD control word (page

) written by Modbus or CANopen

173 = "Cd13": bit 13 of the CMD control word (page

) written by Modbus or CANopen

174 = "Cd14": bit 14 of the CMD control word (page

) written by Modbus or CANopen

175 = "Cd15": bit 15 of the CMD control word (page

) written by Modbus or CANopen

7090

2028 / 5B

LEt

R/WS

Configuration of external fault detection

Factory setting: 1

0 = "LO": The external fault is detected when the logic input assigned to EtF changes at state 0.

Note: In this case, the external fault can not be assigned to a bit of Modbus or CANopen control

word.

1 = "HIG": The external fault is detected when the logic input or the CMD control word bit

assigned to EtF changes at state 1.

Note: If LEt = HIG, EtF is assigned to a bit of Modbus or CANopen control word and there is

no EtF detected fault, the change to LEt = LO causes an EtF external detected fault.

In this case, It is necessary to switch off then to switch on the drive.

7006

2028 / 7

EPL

R/WS

Stop mode in the event of an external fault EPF

Factory setting: 1

0 = "nO": External fault ignored

1 = "YES": Freewheel stop

6 = "rMP": Stop on ramp

7 = "FSt": Fast stop

9611

2042 / C

OPL

R/WS

Configuration of motor phase loss detection

Factory setting: 1

0 = "nO": Function inactive

1 = "YES": Triggering of OPF detected fault

2 = "OAC": No OPF fault triggered but management of the output voltage in order to avoid an

overcurrent when the link with the motor is re-established and flying restart even if FLr = nO.

To be used with downstream contactor.

OPL is forced to YES if brake control bLC is assigned (page

).

If OPL = OAC, bLC is forced to nO (page

).

7002

2028 / 3

IPL

R/WS

Configuration of line phase loss detection

Factory setting: 1 except for ER23

ppp

M2: 0

This parameter is only active on 3-phase drives.

0 = "nO": Ignored

1 = "YES": Fast stop