5 BBL Single Wall Hybrid Brewhouse V6

© Blichmann Engineering, LLC 2022

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts

2

What’s In the Box?

Item Number

Description

Qty

BE-000633-00

1.5” Sanitary Tri-Clamp

3

BE-000868-00

1.5” TC Gasket

3

BE-001132-01

3.5BBL Boil Kettle Stand Pip

2

BE-001361-01

1.5” TC Thermowell with 1/2" FNPT inlet

3

BE-001612-00

RTD PT100 Temp Sensor

3

BE-001634-00

1/2” NPT Cable Gland, 3-7mm

3

BEPS-ControlKit-3Ves

- Control Panel Accessory Kit

Parts List:

Item Number

Description

Qty

BE-000096-01

Brush for Level Gauge - 30”

1

BE-000630-00

1.5” Cap

1

BE-000633-00

1.5” Sanitary Tri-Clamp

7

BE-000859-00

2.5” Cap

1

BE-000861-00

2.5” Sanitary Tri-Clamp

1

BE-000863-00

1.5” TC Elbow - 90°

3

BE-000866-00

2.5” TC Gasket

1

BE-000868-00

1.5” TC Gasket

7

BE-001236-00

CIP Spear for Pin Style Spray Ball

1

BE-001084-01

CIP Rotary Sprayball

1

BE-001356-00

1.5” TC Butterfly Valve

2

BEPS-BK/HLT-Parts-3.5BBL

- 3.5BBL BK & HLT Parts

Kit Parts List (

1 of 2

):

Item Number

Description

Qty

BE-000096-01

Brush for Level Gauge - 30”

1

BE-000630-00

1.5” Cap

1

BE-000633-00

1.5” Sanitary Tri-Clamp

7

BE-000859-00

2.5” Cap

1

BE-000861-00

2.5” Sanitary Tri-Clamp

1

BE-000863-00

1.5” TC Elbow - 90°

3

BE-000866-00

2.5” TC Gasket

1

BE-000868-00

1.5” TC Gasket

7

BE-001236-00

CIP Spear for Pin Style Spray Ball

1

BE-001084-01

CIP Rotary Sprayball

1

BE-001356-00

1.5” TC Butterfly Valve

2

BEPS-BK/HLT-Parts-3.5BBL

- 3.5BBL BK & HLT Parts

Kit Parts List (

2 of 2

):

Item Number

Description

Qty

BEPS-SanitaryHose-1in-7

1”x7’ Hose Assembly

3

BEPS-SanitaryHose-1in-12

1”x12’ Hose Assembly

1

BEPS-Sanitary Hose5

- Hoses for Hose Kit Parts

List:

Item Number

Description

Qty

BE-000633-00

1.5” Sanitary Tri-Clamp

8

BE-000868-00

1.5” TC Gasket

8

BEPS-HoseKitHardware-3V

- Hose Kit

Hardware Parts List:

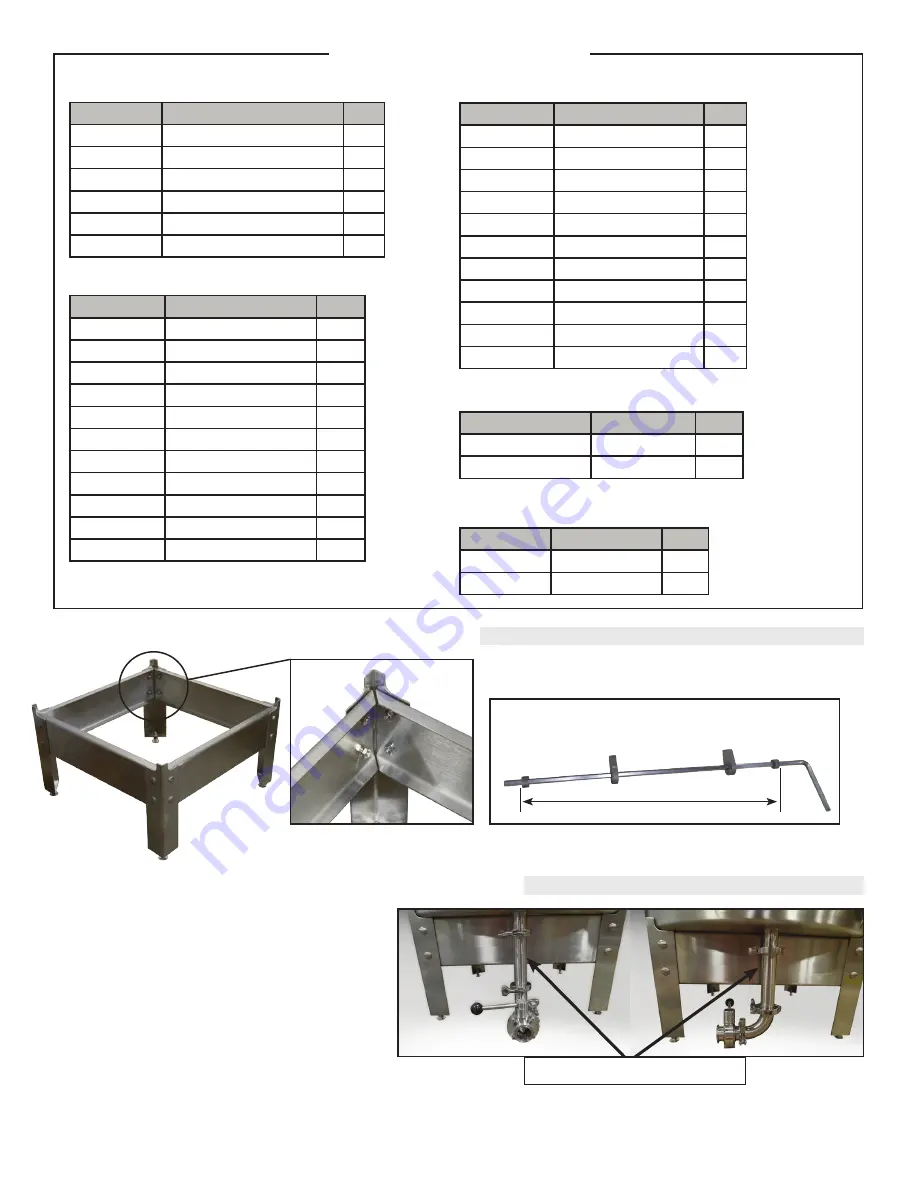

ASSEMBLE THE KETTLE STANDS AS SHOWN

LIFTING ARM ASSEMBLY

Attach the lifting arm to the holes in the mash kettle strand.

Use the included allen wrench to tighten in place.

Kettle stand walls

Place stands in the desired location Use a level to ensure

that the stand arms are level. Adjust the leveling feet

as needed. It is recommended that you allow enough

clearance between kettles and also on the sides and rear

to allow personnel access for cleaning and service of

the ancillary equipment. Although in practical use, the

kettles can easily be slid out for any service needs.

Install valves and fittings as shown in the images below.

Note that a 6” spool is added to the mash tun drain to

allow the valve to swing under the stand so that a spent

grain tote can be placed under the manway. It is not

necessary to add the spool to the BK/HLT.

SPOOL FOR MASH TUN ONLY

KETTLE PLACEMENT & FITTINGS INSTALLATION