WineEasy™ V2

© Blichmann Engineering, LLC 2018

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts

5

Sanitation:

Caution:

do

NOT

use any cleaner or sanitizer containing

chlorine

such as bleach on stainless steel. Over time, this will pit and

erode stainless steel. Never soak parts overnight of extended periods in sanitizer as this may lead to galvanic corrosion of the

parts. Any other non-chlorine sanitizer is acceptable to use.

Sanitizers:

A sulfite/citric acid solution is the traditional choice. Another option is StarSan

tm

from Five Star Chemicals. This food

grade no-rinse phosphoric acid based product is very popular in the food and brewing industry. It contains a surfactant which

will penetrate crevices better than other sanitizers, and works outstanding in a spray application. Contact your home wine making

store for availability.

Cleaners:

Caustic (soda ash) is the traditional cleaner for stainless in the home and commercial wine making industry, and may

be used on any of the fittings and parts of the WineEasy

tm

. A safer option to caustic is another product from Five Star Chemicals

- PBW (powdered brewery wash). This product is an environmentally friendly alkaline cleaner with a surfactant to lift heavy soils.

A hot water rinse is all that’s needed after cleaning.

Warning:

Caustic is a hazardous chemical and will dissolve skin! It is particularly dangerous if it enters the eye. Always use safety

glasses and protective gloves when using caustic, and always follow the manufacturer’s recommendations when using their prod-

uct!

Initial Cleaning:

Prior to the first use, and after each subsequent use, scour the lid and tank with caustic (or PBW) and a Scotch-

brite

TM

type green scouring pad or a sponge to remove any remaining manufacturing residues and oil. Do not use a steel wool

scouring pad as the metal particles will rust on the surface of the parts. Rinse well and allow to dry thoroughly. Drying thoroughly

allows a protective layer to naturally re-form on the surface of the stainless steel as the oxygen in the atmosphere naturally reacts

with the chromium in the stainless to form CrO

2

– a highly corrosion resistant compound. This reaction is what makes stainless

steel stainless! Scrub the fittings with a nylon brush and caustic or hot PBW and rinse with hot water then into your sanitizer. If

you are not going to immediately use the fermentor, dry the fittings and seals thoroughly, and store them in a new plastic zip-lock

bag inside your fermentor.

Before each use:

After washing, soak all fittings, valves, o-rings and lid seal in a sanitizing solution.

CAUTION: only fill the fermentor ¾ full to allow adequate space for the cap to rise!

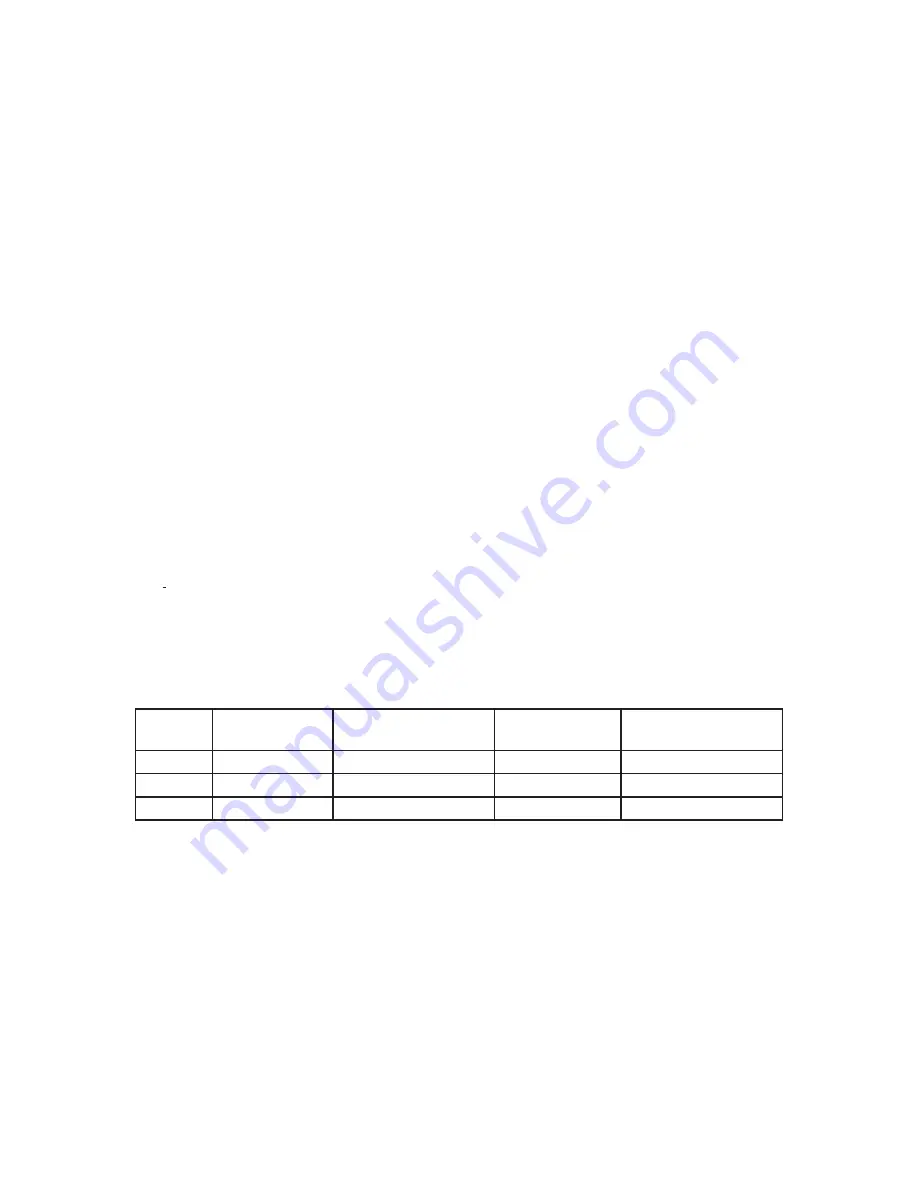

Capacity chart:

Gross Volume

(gal)

Max Must Volume (gal)

Max Must

(lb/Kg)*

Gross Finished

Wine (gal)*

20 gal

20

15

150/68

10

30 gal

30

23

230/104

15

55 gal

55

42

420/190

27

*Finished wine and must weight/vol are approximations due to varietal differences and other variables.

Ferment as you would any primary alcoholic fermentation punching down the cap 2-3 times daily. The lid provides a fairly tight

seal and the CO

2

production from fermentation will keep oxygen out of the fermentor during alcoholic fermentation. If you spill

wine or skins on the lip of the tank or lid while punching the cap, wipe it off with a paper towel soaked in sulfites or vodka to

reduce the chances of bacterial contamination from fruit fly infestation. We also recommend using a sanitized rubber spatula to

wipe any skins off the sidewall of the fermentor after each punch-down.

When alcoholic fermentation is complete you are ready for the free run and pressing step.