Lit. No. B64092, Rev. 09

14

April 15, 2021

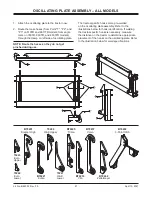

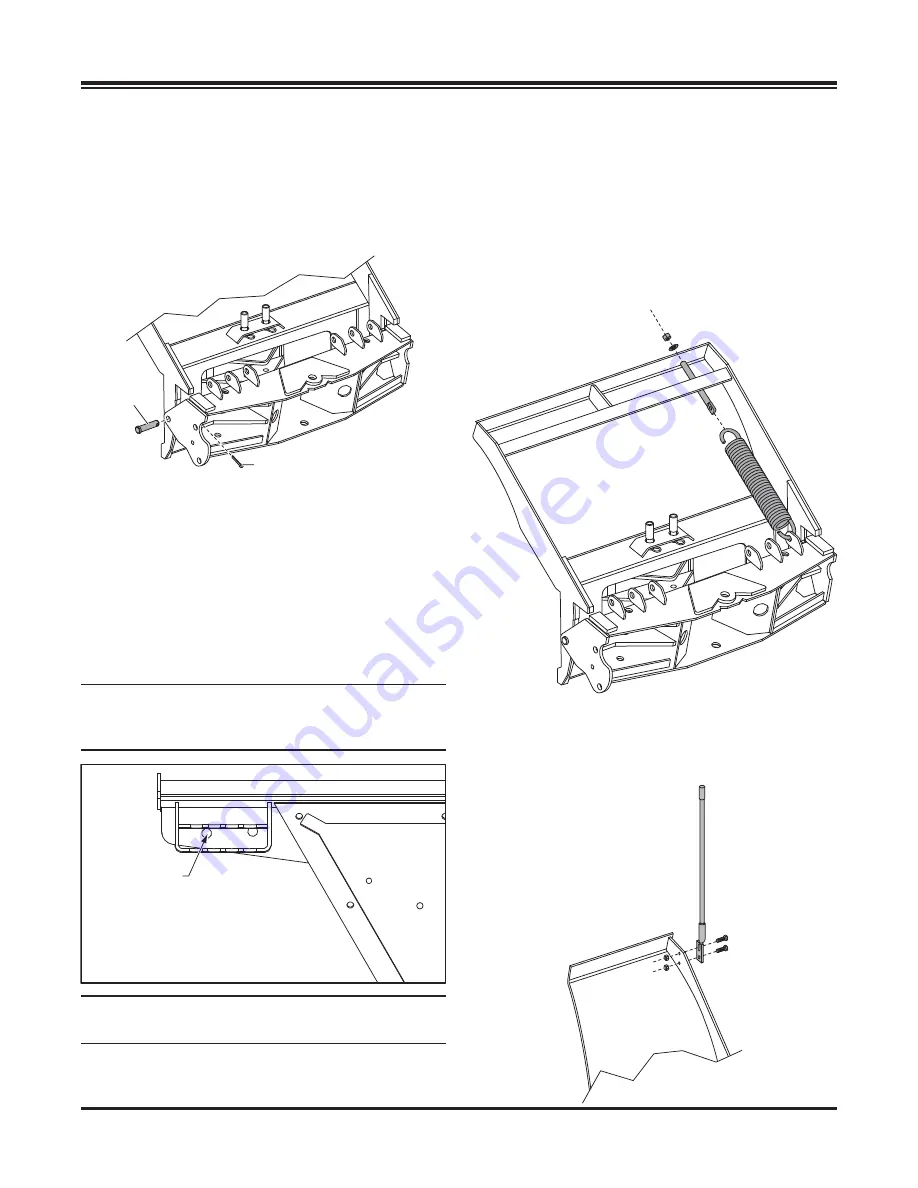

MOLDBOARD & A-FRAME ASSEMBLY – 810TR, 8100TR & 8611TR MODELS

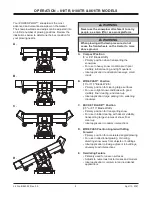

5. Position the pivot beam between the two

support ribs until the connecting points on the

beam align with those on the snowplow. Insert

one 3/4" x 3" clevis pin (

B50069

) through

each mounting hole and secure them with

1/4" x 1-1/2" cotter pin (

90601

).

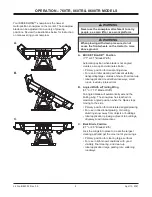

6. Position each angle cylinder with the rod

end of the cylinder in the pivot beam and

the hydraulic hose port facing away from

the A-frame. Secure the cylinder to the pivot

beam with a 3/4" x 5" clevis pin (

95739

) and a

1/4" x 1-1/2" cotter pin (

90601

). Extend each

cylinder rod until the cylinder base mounting hole

aligns with the hole on the A-frame angle cylinder

bracket. Insert another clevis pin and secure it

with a cotter pin.

NOTE: Be sure to use the proper mounting point

when replacing or installing cylinders on 8611TR

models.

NOTE: The cylinder ports should be facing away

from the A-frame.

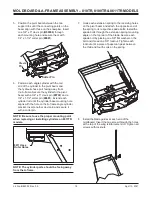

7. Hook each extension spring to the receiving holes

on the pivot beam and attach the opposite end of

the spring to its respective spade bolts. Install the

spade bolts through the extension spring mounting

angle on the top rear of the blade. Secure each

spade bolt by placing one 5/8"

fl

at washer on the

bolt and thread one 5/8" locknut. Tighten each

locknut until a piece of paper can pass between

the third and fourth coils on the spring.

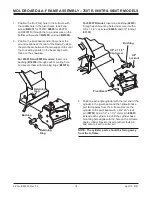

8. Install the blade guides at each end of the

moldboard. Insert the cap screw through the holes

at the top of the wing reinforcement rib. Tighten all

screws with locknuts.

8611 Uses

Outer Holes

Clevis

Pin

Cotter Pin

Summary of Contents for 760TR

Page 2: ......