Lit. No. B64092, Rev. 09

27

April 15, 2021

REMOVING FROM STORAGE

1. Perform all regular maintenance.

2. Replace the hydraulic

fl

uid in the hydraulic system.

Prolonged storage could result in condensation

build-up.

3. Follow the mounting procedure on the Mounting

and Dismounting label.

4. Initiate all of the functions and test before using.

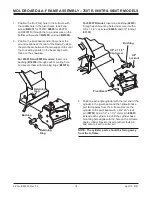

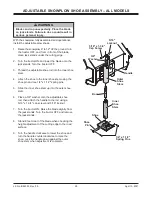

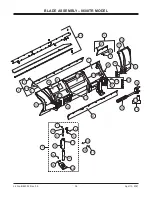

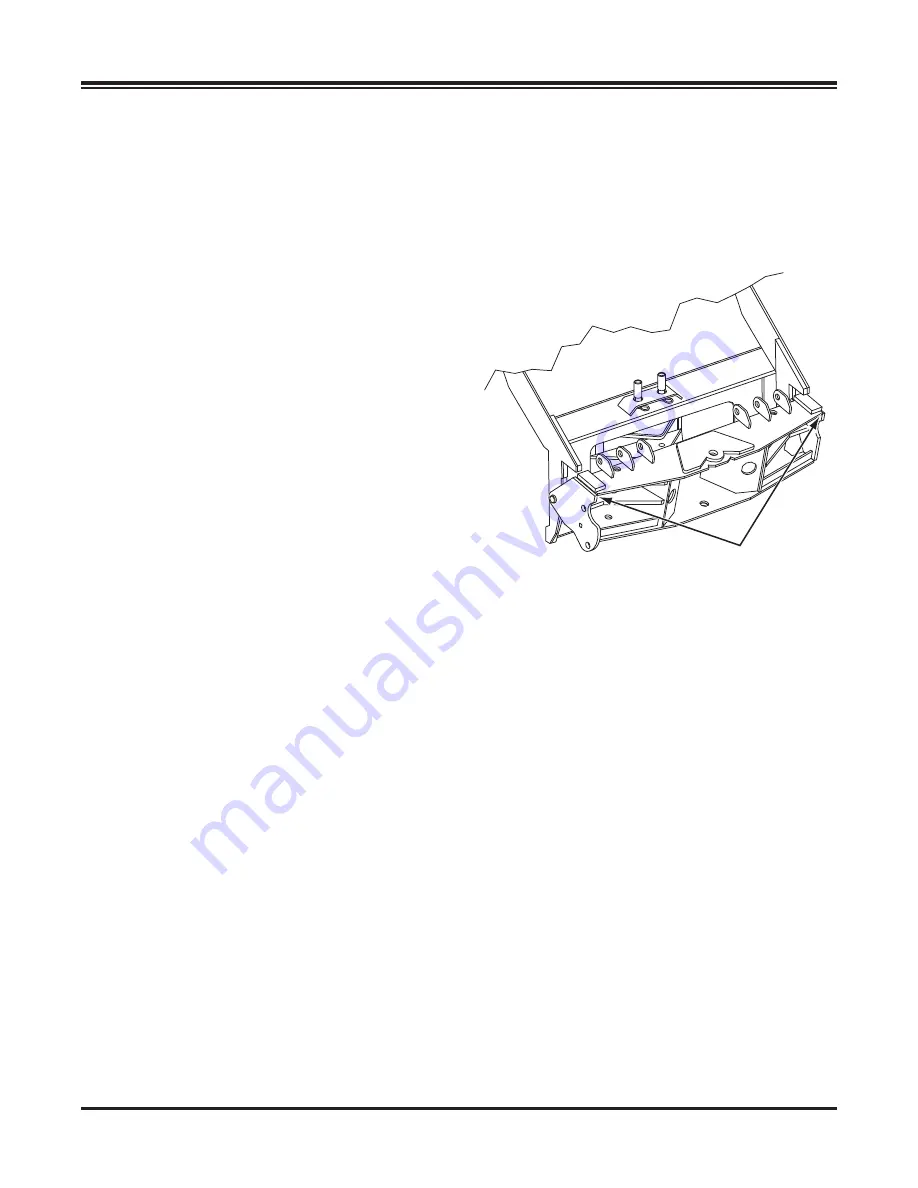

LIFTING

To lift and move this snowplow, attach chain fall

grab hooks to outside pivot beam area shown.

Always follow recommended lift warnings and

procedures. See the following page for snowplow

weights and dimensions.

Lifting Points

(both sides)

REMOVING FROM STORAGE & LIFTING

Summary of Contents for 760TR

Page 2: ......