Lit. No. B64090, Rev. 07

25

June 15, 2010

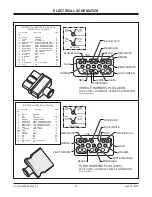

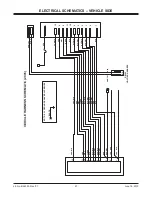

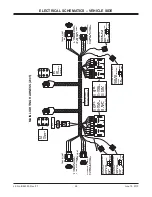

ELECTRICAL INSTALLATION – VEHICLE SIDE

12. Connect the power wire (with 15 amp fuse) to

a switched power source with a minimum of 15

amps.

NOTE: The red power wire MUST be fused and

switched ON and OFF with ignition.

Secure all loose wires under the dash.

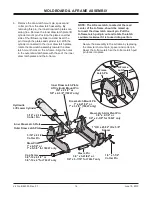

13. Install the light tower. Position the arms into the

receiving pockets located on the undercarriage.

Each pocket has a lock pin that secures both light

tower arms. Pull out and twist each handle to

temporarily unlock the pins. Place the light tower

into the pockets and relock the pins. See your

local BLIZZARD

®

dealer for complete Installation

Instructions for your vehicle undercarriage.

14. Install the snowplow headlamps. Align one

headlamp stud on the light tower tube with the

mounting hole and insert the threaded stud

through each. Secure the headlamp with one

1/2" galvanized washer (neoprene facing up), one

7/16" lock washer and locknut.

NOTE: All snowplows are shipped with two caps

that install on the ends of the light tower.

After adding a liberal amount of dielectric grease,

connect the terminals from the snowplow

headlamps to the terminals on the main lighting

harness.

15.

If using a joystick control

, align the mount holes

on the joystick control with the holes located on

the mount pedestal.

NOTE: The radius on the pedestal should face the

dashboard.

Secure the joystick to the pedestal with the

8 x 3/4" machine screws provided. Slide the

hook-and-loop fastener strap through the slots

cut in the pedestal. The D-ring should be located

on the side opposite of the radius. Wrap the strap

around the bench and fasten.

16. Connect the white power connector from the

vehicle wire harness to the connector on the

control station. The power switch should be in the

"OFF" position.

NOTE: The operation of the draw latch can only

be controlled when the switch on the control

is in the "POWER HITCH™" position and the

"RAISE/LOWER" rocker switch on the A-frame is

in the neutral (center) position.

17. After completing the mechanical and electrical

installations, test all snowplow and lighting

functions before attempting to drive or plow.

Joystick Control

Touchpad Control