大型风扇行业的领航者

if head room is a problem-as long as there is adequate“breathing room” above the fan.

But, be advised that sometimes a fan would run with almost no sway when hung from our

free swiveling mount, will sway radically when bolted directly to a lightweight beam of

commonly found in steel building. This is because a slight imbalance can, at a certain

rpm, excite the natural frequency of the beam in torsion, thereby amplifying the sway. Also,

without the free swiveling mount, more noise is telegraphed back to the building structure.

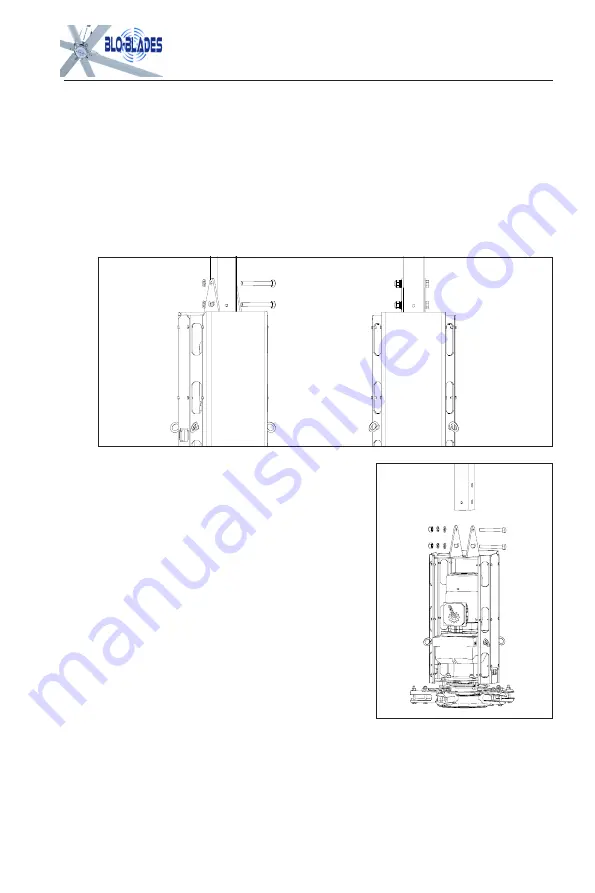

4.3

Installation of the drive device

(1)

The drive device has been installed into a unit before shipping out, only fix it to the

extension rod by using bolts, as shown in figure 4.3.

(2)D

ue to the drive device weight, 2-3 people are

needed to install. If there is a scissors lift, you can use the

lift to assist in assembly, the hoisting weight of the lifting

equipment shall not be less than 440lbs, the hoisting

process must be slow, even, and at the same time it needs

someone to hold the drive device, to prevent oscillation.

(3)

Do not remove oil plug until fan is properly mounted. If

the oil plug is removed before the fan is mounted, oil in the

gear reducer may spill out.

4.4

Run the conduit and install wiring,

(1)

along the facility structure, along the top of the beam layout, per code.

15

Fig4.3

Installation of the driving unit