9

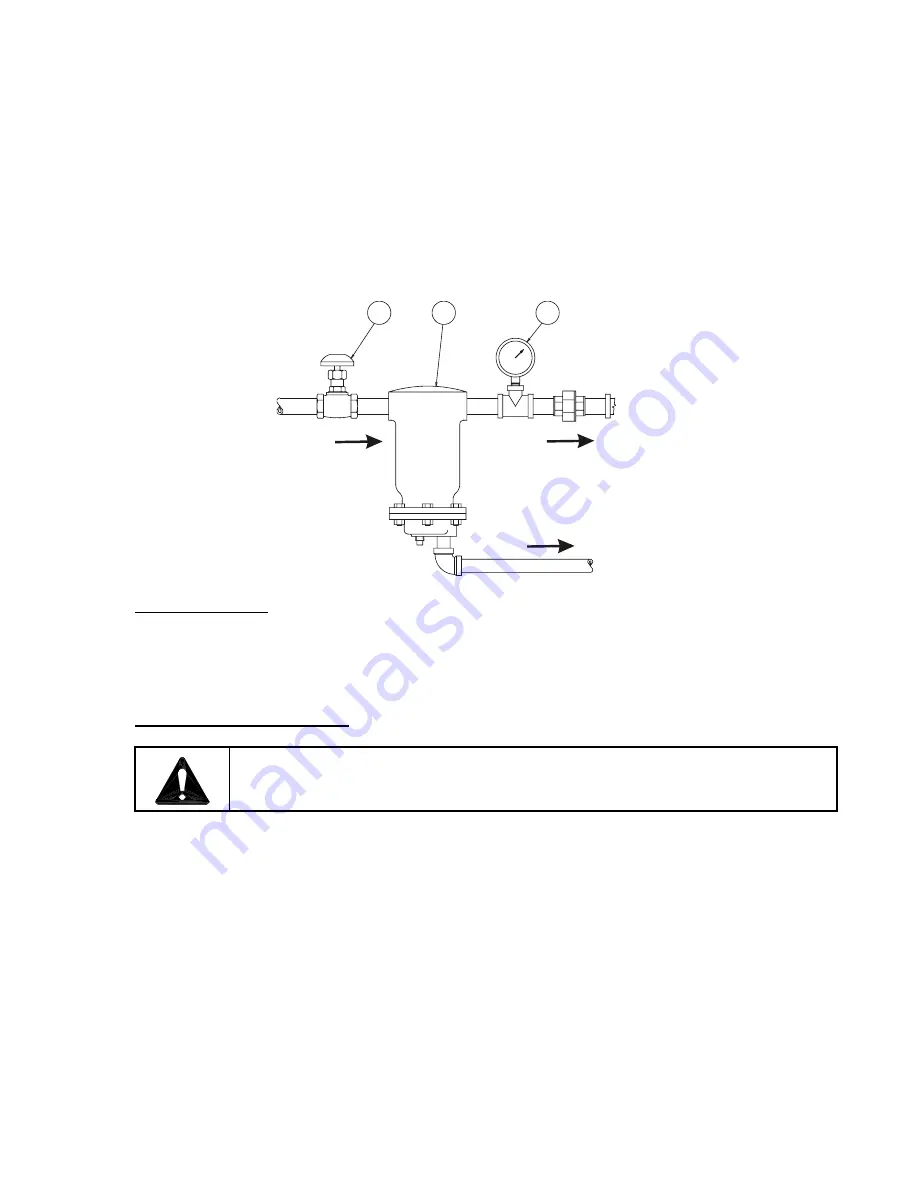

It is suggested that, wherever possible, the steam supply line to the appliance is a

separate line from the steam source. If the appliance must be supplied from a line

supplying other appliances, the pipe sizes and pressure will have to be verified.

Further, during idle periods, when the steam in the supply line is not in use, water will

form from condensed steam in the supply line. It is advisable to prevent water

pockets from forming in the steam line and impeding the steam flow when it is

required. Therefore, the steam supply line should be installed level or run slightly

downwards towards the appliance. Install a Ball Float Trap near the appliance to

drain out water (condensed steam) from the line to assure clean dry steam to the

appliance.

EXHAUST HOOD

An exhaust system should be located directly above the boiler to exhaust steam and

heat generated by the boiler.

PLUMBING CONNECTIONS

WARNING: Plumbing connections must comply with applicable

sanitary, safety, and plumbing codes.

Water Supply Connection

The incoming cold water supply connection, at the rear of the boiler cabinet, requires

3/8" tubing and water pressure of 25 - 50 psig. A manual shut-off valve must be

provided convenient to the boiler; this valve should be open when the boiler is in

operation.

Drain Connection

The boiler drain (2" IPS) should be piped to a floor drain near the boiler. There should

be no solid drain connection; an “open gap” between the boiler and the floor drain is

required.

INLET

TO HEAT

EXCHANGER

TO DRAIN

1

2

3