CLEANING INSTRUCTIONS

PROCEDURE: Clean Tea Brewer

PRECAUTIONS: Disconnect brewer from electric power.

Allow brewer to cool.

FREQUENCY: Daily

TOOLS:

Mild Detergent, Clean Soft Cloth or Sponge

Bristle Brush, Bottle Brush

1. Disconnect brewer from electric power.

Allow brewer to cool before cleaning.

2. Remove dispenser.

3. Remove and empty brew chamber.

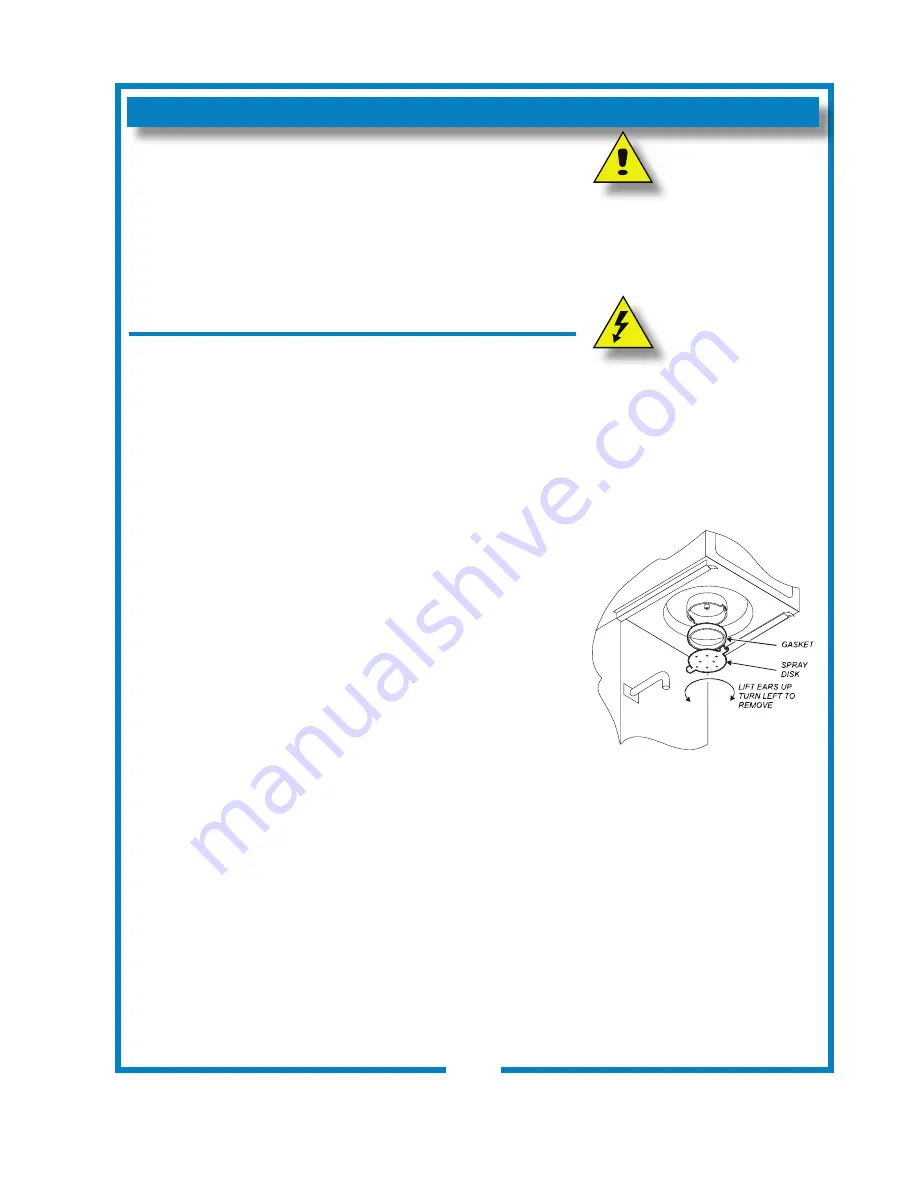

4. Remove the spray disk from the brew head (See figure 8):

Press up on the spray disk ears, then turn the disk to the left

to unlatch. Remove the gasket from inside the brew head.

5. Wipe inside of brew head and area around the brew head

with a soft clean cloth or sponge moistened with clean water.

6. Wash the spray disk in a sink using warm water and a mild

detergent. A bristle brush may be used to clear clogged

spray holes. Rinse the spray disk with clean water and allow

to air dry.

7. Wash the brew chamber in a sink using warm water and a

mild detergent. A bristle brush may be used to clean the

inside. Rinse with clean water and allow to air dry.

8. Wipe the exterior of the brewer with a soft clean cloth or

sponge moistened with clean water.

10. Reinstall the gasket

INSIDE

the brew head, then reinstall the

spray disk.

11. Be sure the wire rack is in place in the brew chamber, then

reinstall the brew chamber.

12. Clean dispensers by filling with warm soapy water. Empty

and rinse with clean water. Wipe the exterior with a soft

clean cloth or sponge moistened with clean water. Invert and

allow to air dry.

Procedure is complete

CAUTION:

BURN HAZARD

Brewing and serving

temperatures of tea are

extremely hot.

Hot tea will cause serious skin

burns.

CAUTION:

SHOCK HAZARD

Do not submerge or immerse

brewer in water.

IMPORTANT:

DO NOT use steel wool, sharp

objects, or caustic, abrasive or

chlorinated cleansers to clean

the brewer or dispensers.

Fig. 8 Cleaning

9

IL1677

606 Owners Manual for 8742-8748 T

ea Brewer 2M-761

16

606

Owners

Manual

for

8742-8748 T

ea

Brewer

2M-761

16