•

Bearings: Spherical/cylindrical roller and ball bearing

combinations; minimum 100,000 hour design life.

•

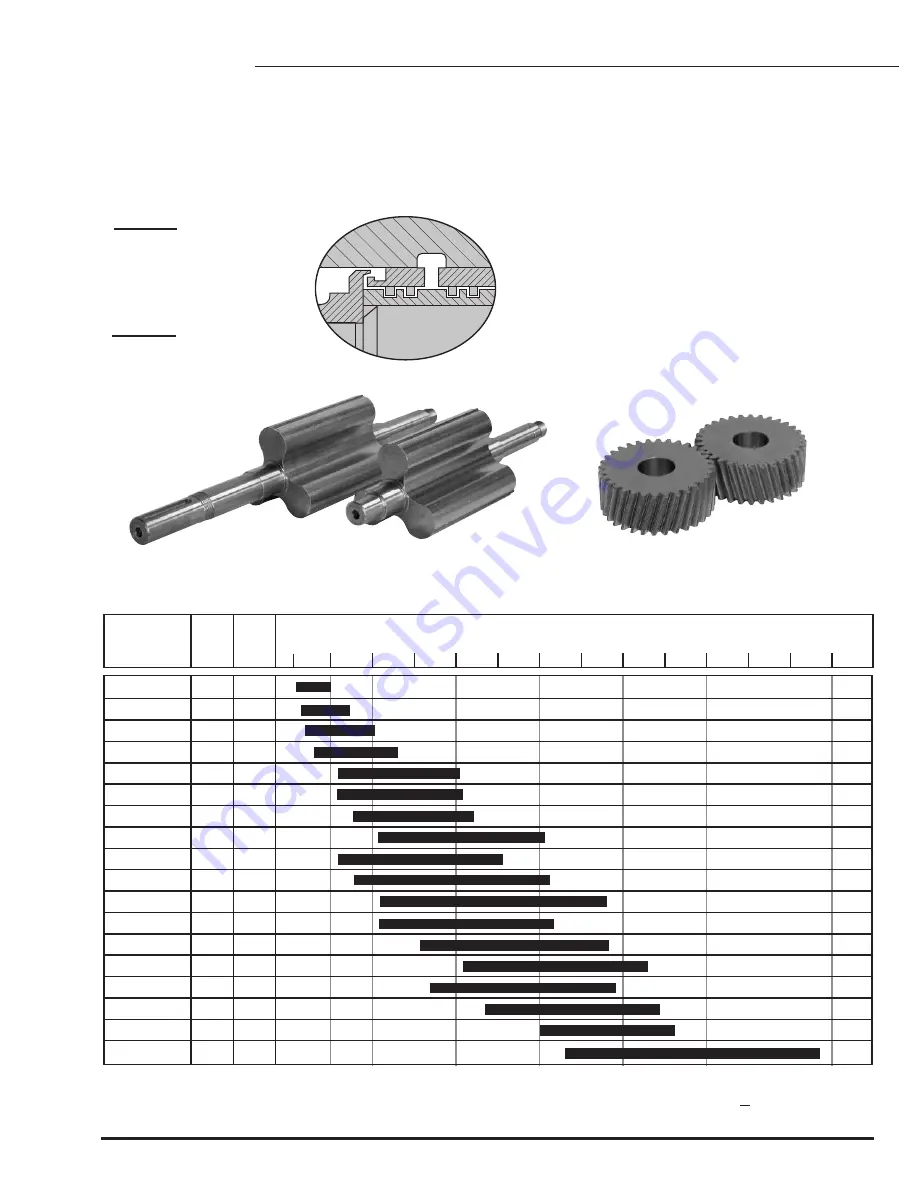

Tri-Lobe Rotors: Involute contoured impeller profiles

for maximum efficiency.

•

Impeller/Shaft Rigidity: Reduces mechanical deflection

and vibration.

•

Oil Seals: Simple non-wearing

slinger type oil seals, provide

positive sealing in both oil

sumps. Unaffected by high

temperatures. No shaft wear.

•

Air Seals: Piston ring air seals

provide dependable non-wearing

operation to minimize air leakage past

the shafts.

•

Heavy-Duty and ribbed cast iron housing and

end covers: Reduce noise levels and increase heat

dissipation.

•

Versatile Mounting: Horizontal or vertical airflow

is easily achieved by relocating the removable

mounting feet incorporated in all models.

•

Splash Oil Lubrication: Assures improved bearing

life and operational simplicity.

•

Gas or air is delivered in an uncontaminated,

oil free state.

•

The unit may be coupled directly or driven

by V-belts.

•

Rotation of the impellers is synchronized by a

pair of timing gears having helical, hardened

and ground teeth.

Design Features

145

300

600

1200 2400 4800 5200

Vacuum

Max

" Hg

∆

P

Max

PSIG

Tri-Lobe

Model

Inlet Volume CFM

30

TRI-LOBE BLOWER PERFORMANCE

Pressure Performance data based on the following; Gas handled: Air, Inlet pressure: 14.7 PSIA, Inlet Temp.: 68ºF

Vacuum Performance data based on the following; Gas handled: Air, Discharge pressure: 29.92 HG A, Inlet Temp.: 68ºF

TL 10

13

13

TL 20

13

13

TL 30

15

15

TL 40

15

15

TL 41

11

12

TL 50

15

15

TL 60

15

15

TL 61

11

12

TL 70

15

15

TL 80

15

15

TL 81

11

12

TL 90

15

15

TL 100

15

15

TL 101

10

12

TL 110

15

15

TL 120

12

13

TL 600

15

15

TL 900

12

13

Blower Engineering Instructional Manual

20

Summary of Contents for Tri-Lobe TL Series

Page 1: ......