MAGNUM ETX

Installation

Page | 15

Cooling

Efficient cooling is essential for long and reliable operation of any electronic equipment. The VIA Eden/C7

CPU, the VIA CN700 Northbridge and VIA VT8237 Southbridge do get hot in normal operation, and in an

elevated ambient temperature will require additional cooling. Cooling requirements will vary with application,

desired operating temperature, CPU load, and memory size and board orientation.

Mounting the PCB vertically will aid natural convection and create a chimney effect. Passive heat sinks can be

used for the CPU, Northbridge and Southbridge. A fan, whilst not always desirable, will provide a high degree

of cooling even for a relatively slow airflow.

Further options that may be considered are sinking heat to the chassis or enclosure and in extreme situations the

use of a heat pipe.

The CPU is equipped with an onboard thermal diode for temperature monitoring. A thermistor is available to

monitor the temperature of critical and potential hot spots on the board. Temperatures can be monitored in the

BIOS Set-up. If you wish to monitor these temperatures from your application please contact the Blue Chip

Technology Technical Support team.

When designing an enclosure, bear in mind that the greater the volume of air that can flow through the

enclosure, the greater the cooling effect and the lower the temperature rise above the ambient air temperature.

However, the volume produced by any fan will vary with the pressure against which it has to work. The

resistance to airflow (the back-pressure on the fan) will depend upon the enclosure, the mounting and

restrictions. Therefore, when mounting and cabling the board, it is essential that the free circulation of the

cooling airflow is not impeded.

The calculation of airflow through an enclosure is not straightforward, and depends on many factors. The

method of meeting the cooling requirements will be specific for each system. Consequently, the system builder

is responsible for ensuring adequate cooling. However, interpreting airflow volumes is not intuitive. As an aid

to selecting suitable cooling, the following example is offered. A 60 mm axial fan (such as a Papst type

612NGH) blowing over the board can supply up to 46 m

3

/hour when unrestricted. Restrictions to the airflow

will reduce this volume.

Blue Chip Technology offers several cooling solutions to help manage cooling:

Heat plate designed to allow contact with a larger cooling area such as direct contact with a metal

enclosure

A passive finned heatsink

An active solution based on the finned heatsink with a fan (12 m

3

/hour) attached

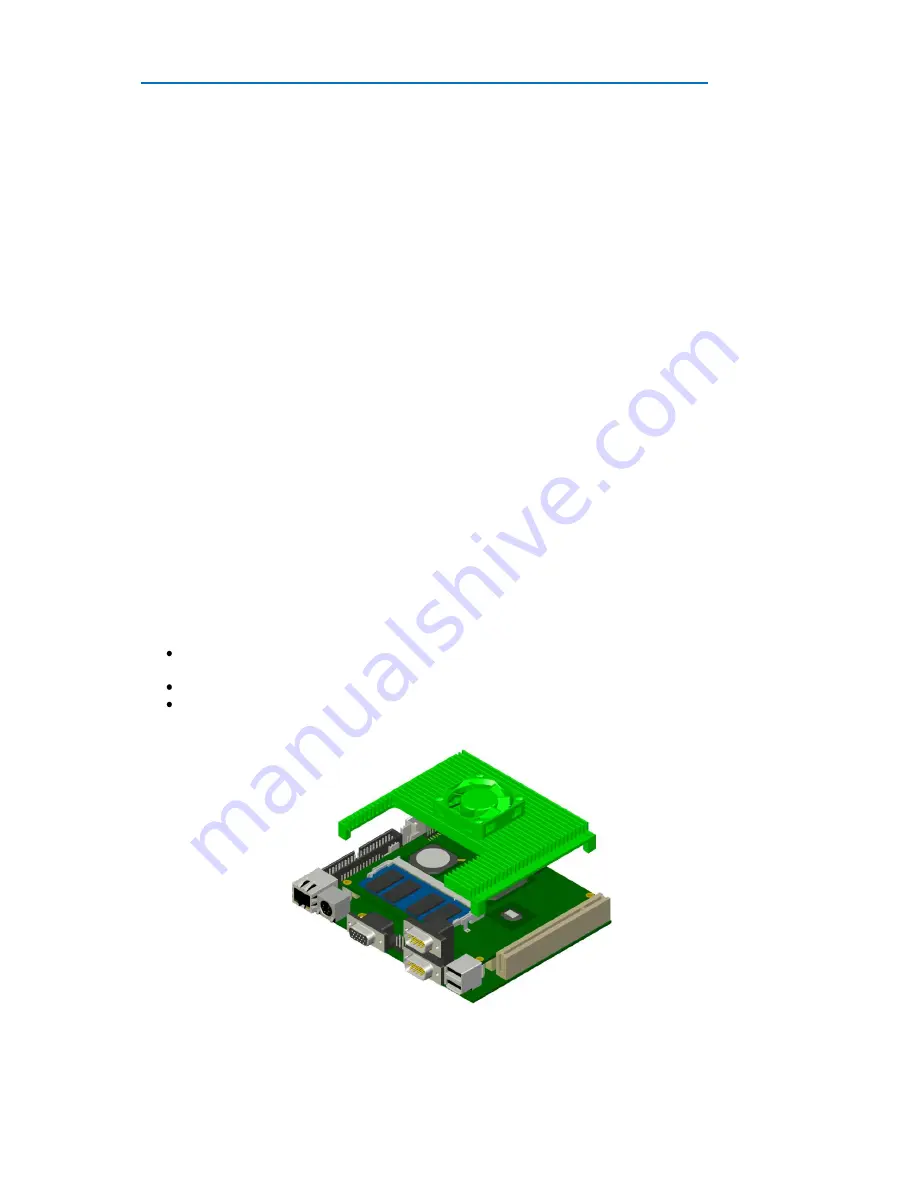

Figure 4: Position Heatsink above daughter board