2.4 Specific life cycles of the AIRSKIN® Safetyflange

2.4.1 Transport

The AIRSKIN® Safetyflange and all its components should be transported and stored in the packaging intended

for this purpose. When it is removed from its packaging, you should carry out a visual inspection to check for any

damage to the metal parts and/or deformation of the soft plastic parts. It might be necessary to replace some of

these parts.

2.4.2 Installation/assembly

Assembly by trained personnel must only be undertaken if the robot is switched off. Correct installation and

functionality must be tested prior to initial operation; this should be done in the robot’s manual mode and at the

lowest possible speed. These tests also require compliance with ISO/TS 15066.

You can find information about assembly in

2.4.3 Servicing and maintenance

Authorization to operate the machine no longer applies if the safety functions of the AIRSKIN® Safetyflange are

disabled or bypassed mechanically, electrically, or in any other way.

Any servicing or maintenance jobs require the machine on which the AIRSKIN® Safetyflange is installed to be

switched off or disconnected from the electricity supply.

A visual inspection of the AIRSKIN® Safetyflange should be conducted at least once a month in order to identify

any early signs of damage, plastic deformation or other changes. In the case of plastic deformation (e.g. due

to mechanical wear & tear, excessive use, use in increased temperatures, intensive contact with solvents, etc.),

the risk assessment or working instruction may need to be adapted and/or the AIRSKIN® Safetyflange must be

replaced.

Annual maintenance must be carried out by trained personnel using equipment that has been provided by Blue

Danube Robotics. You can find information about annual maintenance in

Following appropriate consultation, any defective AIRSKIN® Pads or defective mechanical components can be

returned (postage-free) to Blue Danube Robotics. In those cases where the warranty applies, faulty components

must likewise be returned to Blue Danube Robotics.

2.4.4 Disassembly

The AIRSKIN® Safetyflange can be disassembled in reverse order by following the assembly instructions which

can be found in

Parts that are defective or no longer used can be returned to Blue Danube Robotics.

2.5 Service life

If used, maintained and stored in accordance with this Manual, you can expect a service life of 10 years for the

AIRSKIN® Safetyflange.

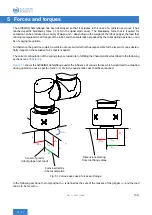

In order to obtain optimal sliding characteristics, the Safetyflange contains components which wear out after

a specific number of actuation procedures (tilt, rotation around the z-axis). It may be necessary to exchange

these elements during a service life of 10 years. After expiry of the service life, the entire safety flange must be

replaced.