10.2 Maintenance jobs

The following maintenance jobs are recommended for AIRSKIN®.

10.2.1 Cleaning of exterior

Cleaning of all the surfaces that can be accessed from the outside, using commercially available alcohol-based

cleaners or isopropanol (

70

%

). Also clean the gaps between the Pads, and in doing so check the connection

hoses of any companion pads for kinks and bruises, as well as all the AIRSKIN® Pads for dents, scratches, paint

defects, discoloration, and any other abnormalities. They must be recorded in the maintenance log.

This maintenance should be carried out as required, but at least once every 3 months.

(a) Exterior cleaning

(b) Interior cleaning

Fig. 10.1: For exterior cleaning, all externally accessible surfaces of the AIRSKIN® system are cleaned. For inte-

rior cleaning, all pads are removed from the machine and cleaned with commercially available alcohol

cleaners or isopropanol (

70

%

).

Cleaning agents compatibility

In order to prevent major damage to the components, the compatibility of cleaning agents,

which are not explicitly recommended by Blue Danube Robotics, must be tested before

extensive use.

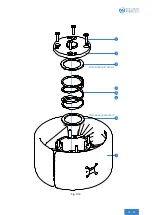

10.2.2 Detailed inspection with interior cleaning

This more extensive maintenance work requires the complete removal of all pads from the machine. Clean each

pad on all sides with commercially available alcohol cleaners or isopropanol (

70

%

). Inspect each pad for dents,

scratches, paint damage, discolouration and other abnormalities as well as the connection hoses of any compan-

ion pads for kinks and bruises.

In addition, special attention should be paid to the internal AIRSKIN® electronics and the mechanical and electrical

connectors that connect each AIRSKIN® pad to the underlying support layer. The AIRSKIN® electronics should be

examined more closely for damage, discolouration, abnormalities and good condition of the visible white filter cap.

The mechanical and electrical connectors (magnetic plugs) as well as all components of the Safetyflange must

be inspected for dirt, tears, other damage, and abnormalities. Any damage or abnormality should be recorded in

the maintenance log and affected parts must be replaced in case of doubt. Full maintenance of the Safetyflange

comprises cleaning of the interior with compressed air together with lubrication of the sliding surfaces.

This maintenance should be carried out as required, but at least once a year.