2.2 Safety instructions for operators

2.2.1 Health & safety at work

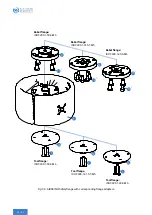

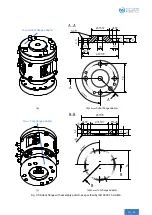

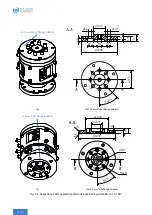

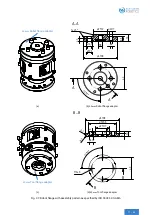

The AIRSKIN® Safetyflange is conceived as collision and crushing protection for tools and workpieces on robots

and machines. In order to guarantee the safety of the machine that is equipped with the AIRSKIN® Safetyflange,

one must comply with the Machinery Directive and ISO/TS 15066 as well as the operating instructions.

Correct configuration of the controller.

The AIRSKIN® Safetyflange can only function safely if the robot controller has been cor-

rectly configured. In order to ensure proper and permissible operation, this configuration

and a risk assessment must be carried out by specialist personnel.

2.2.2 Technical condition of the AIRSKIN® Safetyflange

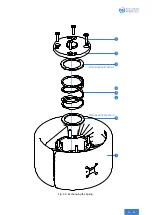

With the exception of exchanging the optional bias springs, the AIRSKIN® Safetyflange must not be altered or

disassembled without the necessary authorization. Any alteration to the installation must be approved by means

of a further risk assessment.

2.3 Safety instructions for personnel

2.3.1 Hazardous situations and accidents

What to do in the case of accidents

1. Report the accident

• Telephone:

• Where did it happen?

• What happened?

• How many people are injured?

• What types of injury are there?

• Wait for follow-up questions!

2. First aid

• Secure the place where the accident has occurred

• Care for anyone who has been injured

• Follow instructions

3. Further measures

• Brief the emergency service(s)

• Disperse any curious onlookers