4-2.

CONTROLLER TROUBLESHOOTING

4-2.1.

Zapi Handset

A Zapi Handset is available that is designed specifi-

cally for use with the Zapi controller. It serves multiple

functions of reading diagnostic data, testing truck

operation, setting options, adjustments and parameter

changes of the controller. The Zapi Handset is avail-

able through your

Blue Giant

dealer. If you require

dealer location information, contact

Blue Giant

.

Remove the rubber plug from the CNC connector of

the controller

and plug in the Zapi Handset

connector.

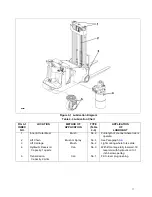

Figure 4-1. Zapi Controller

4-2.2. Fault Detection.

4-2.2.1. General

The controller provides diagnostics information to

assist technicians in troubleshooting problems. When

a fault is detected, an alarm is recorded in the logbook.

It has a FIFO (First Input First Output) structure that

means the oldest alarm is lost when the database is

full and a new alarm occurs. The logbook is composed

of alarms with the following information:

• The alarm code

• The times that each alarm occurs consecutively

• The Hour Meter value when the latest event of every

alarm occurred

• The invert temperature when the latest event of

every alarm occurred.

This function permits a deeper diagnosis of problems

as the recent history can be revisited.

4-2.2.2. Logbook Access

To view the alarm logbook proceed as follows:

1.

Connect the Zapi Handset, refer to paragraph

2.

Press the ROLL down button (1,

) and

the ENTER button (3) at the same time to enter

the MAIN MENU.

3.

Press the ROLL down button (2) or the ROLL up

button (1) to find the ALARMS display.

4.

Press the ENTER button (3) to view the alarms.

5.

Press the OUT button (6) to exit the alarms.

NOTE: Refer to bigjoesupport.com for the Zapi sup-

plement containing detailed information on

alarm codes. There are two versions shown.

The

BGL-22

uses the Standard version

which

lists the error by: Alarm Name,

Repetitions,

Temperature and Hour Meter

reading.

4-2.3. Testing Truck Operation.

The Zapi Handset can be used to test certain truck

operations as follows:

1.

Connect the Zapi Handset, refer to paragraph

2.

Press the ROLL down button (1,

) and

the ENTER button (3) at the same time to enter

the MAIN MENU.

3.

Press the ROLL down button (2) or the ROLL up

button (1) to find the TESTER display.

4.

Press the ENTER button (3) to view the tests.

5.

To verify various switch functions, locate the

switch on the display and then operate that func-

tion to verify operation

6.

Press the OUT button (6) to exit the tests.

R6628

22

Summary of Contents for BGL-22

Page 12: ...NOTES 12...

Page 18: ...NOTES 18...

Page 34: ...NOTES 34...

Page 39: ...Figure 5 4 Cap Assembly R6878 39...

Page 42: ...Figure 6 1 Transmission Motor Brake Assembly R6879 42...

Page 44: ...Figure 7 1 Transmission Motor Brake Assembly R6879 44...

Page 45: ...Figure 7 2 Load Wheels R6882 45...

Page 46: ...NOTES 46...

Page 48: ...Figure 8 2 Elevation System Telescopic R6883 48...

Page 50: ...Figure 8 3 Mast TRIMAST R6884 50...

Page 52: ...NOTES 52...

Page 54: ...Figure 9 1 Hydraulic System R6886 54...

Page 56: ...Figure 9 3 Hydraulic System TRIMAST R6888 56...

Page 58: ...Figure 9 4 Elevation System Telescopic R6883 58...

Page 59: ...Figure 9 5 Lift Cylinder Telescopic R6889 59...

Page 61: ...Figure 9 6 Elevation System TRIMAST R6884 61...

Page 62: ...Figure 9 7 Free Lift Cylinder TRIMAST R6890 62...

Page 64: ...Figure 9 8 Secondary Lift Cylinder TRIMAST R6891 64...

Page 67: ...Figure 9 10 Tilt Cylinder R6893 67...

Page 68: ...NOTES 68...

Page 70: ...Figure 10 1 Electrical System R6478 R6894 70...

Page 71: ...Figure 10 2 Electrical Panel R6478 R6895 71...

Page 73: ...Figure 10 3 Transmission Motor Brake Assembly R6879 73...

Page 74: ...NOTES 74...

Page 75: ...SECTION 11 OPTIONAL EQUIPMENT 75...

Page 76: ...NOTES 76...

Page 78: ...Figure 12 1 Steering System R6876 78...

Page 80: ...Figure 12 2 Control Head R6877 80...

Page 82: ...Figure 12 3 Cap Assembly R6878 82...

Page 85: ...NOTES 85...

Page 86: ...Figure 12 5 Transmission Motor Brake Assembly R6879 86...

Page 89: ...NOTES 89...

Page 90: ...Figure 12 7 Frame R6881 90...

Page 92: ...Figure 12 8 Load Wheels R6882 92...

Page 94: ...Figure 12 9 Elevation System Telescopic R6883 94...

Page 96: ...Figure 12 10 Elevation System TRIMAST R6884 96...

Page 98: ...Figure 12 11 Lift Carriage R6815 98...

Page 101: ...NOTES 101...

Page 102: ...Figure 12 13 Hydraulic System R6665 102...

Page 104: ...Figure 12 14 Pump Motor R6886 104...

Page 107: ...NOTES 107...

Page 108: ...Figure 12 16 Hydraulic System TRIMAST R6888 108...

Page 110: ...Figure 12 17 Tilt Cylinder Mounting R6892 110...

Page 112: ...Figure 12 18 Lift Cylinder Telescopic R6889 112...

Page 114: ...Figure 12 19 Free Lift Cylinder TRIMAST R6890 114...

Page 116: ...Figure 12 20 Secondary Lift Cylinder TRIMAST R6891 116...

Page 118: ...Figure 12 21 Tilt Cylinder R6893 118...

Page 120: ...Figure 12 22 Electrical System R6894 120...

Page 123: ...NOTES 123...

Page 124: ...Figure 12 24 Drive Motor R6630 124...

Page 128: ...NOTES 128...

Page 129: ...129...