SECTION 9

HYDRAULIC SYSTEM SERVICING

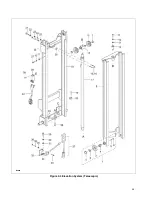

9-1. LINES AND FITTINGS

WARNING:

When forks are raised, pressure exists in

the hydraulic system lines and fittings.

To ensure release of pressure, forks

must be fully lowered and the batteries

disconnected before performing any

maintenance on the hydraulic system.

NOTE:

Leaking hydraulic fittings may be remedied by

simply tightening fittings. If this does not rem-

edy the leak, the fittings or line must be

replaced.

1.

Lower forks fully.

2.

Turn off the key switch (6,

) and dis-

connect the batteries.

3.

Remove the front compartment covers as

described in paragraph

CAUTION:

Hydraulic oil can damage parts. Wipe off

any oil immediately. Provide a container

under the line or fitting before discon-

necting.

4.

Refer to

and

and

remove leaking line or fitting and replace it with a

new line or fitting.

5.

Check level of hydraulic oil. If required, add

hydraulic oil to bring to proper level. Use hydraulic

oil listed in

6.

Reconnect the batteries and turn on the keyswitch

(6,

7.

Operate the lift and lower buttons to refill the

cylinder and lines with hydraulic oil.

8.

Check level of hydraulic oil. If required, add

hydraulic oil to bring to proper level. Use hydraulic

oil listed in

9.

Install the front compartment covers as described

in paragraph

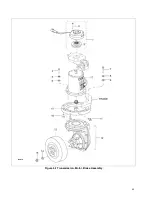

9-2. HYDRAULIC PUMP, AND MOTOR ASSY

WARNING:

When forks are raised. pressure exists in

the hydraulic system lines and fittings.

To ensure release of pressure, forks

must be fully lowered and the batteries

disconnected before performing any

maintenance on the hydraulic system.

9-2.1. Removal

1.

Lower forks fully.

2.

Turn off the key switch (6,

) and dis-

connect the batteries.

3.

Remove the front compartment covers as

described in paragraph

4.

Tag and disconnect electrical leads from pump

and motor (5,

NOTE:

Place a container under the pump assembly

to catch any hydraulic oil.

5.

Tag and disconnect two hoses (13) from pump

and motor (5).

6.

Telescopic Trucks:

Tag and disconnect hose (1.

) from pump and motor (5).

TRIMAST Trucks:

Tag and disconnect hose (18.

) from pump and motor (5)

7.

Remove two screws (1,

), two lock

washers (2) four washers (4) and four washers

(3).

8.

Remove the pump and motor assembly (5) with

reservoir (9).

9.

Remove four bolts (8), four lock washers (7) and

reservoir (9) from pump and motor assembly (5).

9-2.2. Disassembly and Reassembly

1.

Remove the pump and motor assembly (5,

2.

Refer to

for disassembly and reas-

sembly of the pump and motor.

1.

Install the pump and motor assembly (5,

) as described in paragraph

53

Summary of Contents for BGL-22

Page 12: ...NOTES 12...

Page 18: ...NOTES 18...

Page 34: ...NOTES 34...

Page 39: ...Figure 5 4 Cap Assembly R6878 39...

Page 42: ...Figure 6 1 Transmission Motor Brake Assembly R6879 42...

Page 44: ...Figure 7 1 Transmission Motor Brake Assembly R6879 44...

Page 45: ...Figure 7 2 Load Wheels R6882 45...

Page 46: ...NOTES 46...

Page 48: ...Figure 8 2 Elevation System Telescopic R6883 48...

Page 50: ...Figure 8 3 Mast TRIMAST R6884 50...

Page 52: ...NOTES 52...

Page 54: ...Figure 9 1 Hydraulic System R6886 54...

Page 56: ...Figure 9 3 Hydraulic System TRIMAST R6888 56...

Page 58: ...Figure 9 4 Elevation System Telescopic R6883 58...

Page 59: ...Figure 9 5 Lift Cylinder Telescopic R6889 59...

Page 61: ...Figure 9 6 Elevation System TRIMAST R6884 61...

Page 62: ...Figure 9 7 Free Lift Cylinder TRIMAST R6890 62...

Page 64: ...Figure 9 8 Secondary Lift Cylinder TRIMAST R6891 64...

Page 67: ...Figure 9 10 Tilt Cylinder R6893 67...

Page 68: ...NOTES 68...

Page 70: ...Figure 10 1 Electrical System R6478 R6894 70...

Page 71: ...Figure 10 2 Electrical Panel R6478 R6895 71...

Page 73: ...Figure 10 3 Transmission Motor Brake Assembly R6879 73...

Page 74: ...NOTES 74...

Page 75: ...SECTION 11 OPTIONAL EQUIPMENT 75...

Page 76: ...NOTES 76...

Page 78: ...Figure 12 1 Steering System R6876 78...

Page 80: ...Figure 12 2 Control Head R6877 80...

Page 82: ...Figure 12 3 Cap Assembly R6878 82...

Page 85: ...NOTES 85...

Page 86: ...Figure 12 5 Transmission Motor Brake Assembly R6879 86...

Page 89: ...NOTES 89...

Page 90: ...Figure 12 7 Frame R6881 90...

Page 92: ...Figure 12 8 Load Wheels R6882 92...

Page 94: ...Figure 12 9 Elevation System Telescopic R6883 94...

Page 96: ...Figure 12 10 Elevation System TRIMAST R6884 96...

Page 98: ...Figure 12 11 Lift Carriage R6815 98...

Page 101: ...NOTES 101...

Page 102: ...Figure 12 13 Hydraulic System R6665 102...

Page 104: ...Figure 12 14 Pump Motor R6886 104...

Page 107: ...NOTES 107...

Page 108: ...Figure 12 16 Hydraulic System TRIMAST R6888 108...

Page 110: ...Figure 12 17 Tilt Cylinder Mounting R6892 110...

Page 112: ...Figure 12 18 Lift Cylinder Telescopic R6889 112...

Page 114: ...Figure 12 19 Free Lift Cylinder TRIMAST R6890 114...

Page 116: ...Figure 12 20 Secondary Lift Cylinder TRIMAST R6891 116...

Page 118: ...Figure 12 21 Tilt Cylinder R6893 118...

Page 120: ...Figure 12 22 Electrical System R6894 120...

Page 123: ...NOTES 123...

Page 124: ...Figure 12 24 Drive Motor R6630 124...

Page 128: ...NOTES 128...

Page 129: ...129...