• When stacking pallets in racks and it is necessary to

move the load in a raised position, use caution.

Operate truck smoothly.

• Observe applicable traffic regulations. Yield right of

way to pedestrians. Slow down and sound horn at

cross aisles and wherever vision is obstructed.

• Operate truck only from designated operation posi-

tion. Never place any part of your body between the

mast uprights. Do not carry passengers.

• Do not allow anyone to stand or pass under load or

lifting mechanism.

• When leaving truck, neutralize travel control. Fully

lower lifting mechanism and set brake. When leaving

truck unattended, turn off key switch, remove key

and disconnect battery.

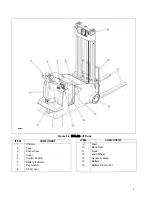

2-3.

BEFORE OPERATION

covers important inspection points on the

BGL-22

lift truck which should be checked prior to

opera-tion. Depending on use, some trucks may

require

additional checks.

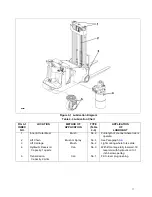

shows a sample format for an Operator

Checklist, which can be modified as necessary to fit

your operation.

WARNING:

Periodic maintenance of this truck by a

QUALIFIED TECHNICIAN is required.

CAUTION:

A QUALIFIED SERVICE TECHNICIAN

should check the truck monthly for

proper lubrication, proper fluid levels,

brake maintenance, motor maintenance

and other areas specified in the

WARNING:

If the truck is found to be unsafe and in

need of repair, or contributes to an

unsafe condition, report it immediately to

the designated authority. Do not operate

it until it has been restored to a safe

operating condition. Do not make any

unauthorized repairs or adjustments. All

service must be performed by a qualified

maintenance technician.

Table 2-1 Operator Checks

ITEM

PROCEDURE

Transmission

and hydraulic

systems.

Check for signs of fluid leakage.

Forks

Check for cracks and damage;

and, that they are properly

secured.

Chains, cables

and hoses

Check that they are in place,

secured correctly, functioning

properly and free of binding or

damage.

Guards and load

backrest

Check that safety guards are in

place, properly secured and not

damaged.

Safety signs

Check that warning labels,

nameplate, etc., are in good

condition and legible.

Horn

Check that horn sounds when

operated.

Steering

Check for binding or looseness in

steering arm when steering.

Travel controls

Check that speed controls on

control head operate in all

speed ranges in forward and

reverse and that belly button

switch functions.

Wheels

Check drive wheel for cracks or

damage. Move truck to check

load for freedom of rotation.

Hydraulic

controls

Check operation of lift, lower and

tilt to their maximum positions.

Brakes

Check that brakes actuate when

steering arm is raised to upright

position, and when lowered to

horizontal position.

Deadman/

Parking brake

Check that steering arm raises to

upright position when released

and brake applies.

Battery

disconnect

Check that battery can be

disconnected and recon-

nected. Check for connector

damage.

Battery charge

Check the battery indicator.

High speed limit

switch

Allow for enough space to oper-

ate truck in high speed. Elevate

forks approximately two feet,

then test drive truck to check if

high speed is cut out.

ITEM

PROCEDURE

8

Summary of Contents for BGL-22

Page 12: ...NOTES 12...

Page 18: ...NOTES 18...

Page 34: ...NOTES 34...

Page 39: ...Figure 5 4 Cap Assembly R6878 39...

Page 42: ...Figure 6 1 Transmission Motor Brake Assembly R6879 42...

Page 44: ...Figure 7 1 Transmission Motor Brake Assembly R6879 44...

Page 45: ...Figure 7 2 Load Wheels R6882 45...

Page 46: ...NOTES 46...

Page 48: ...Figure 8 2 Elevation System Telescopic R6883 48...

Page 50: ...Figure 8 3 Mast TRIMAST R6884 50...

Page 52: ...NOTES 52...

Page 54: ...Figure 9 1 Hydraulic System R6886 54...

Page 56: ...Figure 9 3 Hydraulic System TRIMAST R6888 56...

Page 58: ...Figure 9 4 Elevation System Telescopic R6883 58...

Page 59: ...Figure 9 5 Lift Cylinder Telescopic R6889 59...

Page 61: ...Figure 9 6 Elevation System TRIMAST R6884 61...

Page 62: ...Figure 9 7 Free Lift Cylinder TRIMAST R6890 62...

Page 64: ...Figure 9 8 Secondary Lift Cylinder TRIMAST R6891 64...

Page 67: ...Figure 9 10 Tilt Cylinder R6893 67...

Page 68: ...NOTES 68...

Page 70: ...Figure 10 1 Electrical System R6478 R6894 70...

Page 71: ...Figure 10 2 Electrical Panel R6478 R6895 71...

Page 73: ...Figure 10 3 Transmission Motor Brake Assembly R6879 73...

Page 74: ...NOTES 74...

Page 75: ...SECTION 11 OPTIONAL EQUIPMENT 75...

Page 76: ...NOTES 76...

Page 78: ...Figure 12 1 Steering System R6876 78...

Page 80: ...Figure 12 2 Control Head R6877 80...

Page 82: ...Figure 12 3 Cap Assembly R6878 82...

Page 85: ...NOTES 85...

Page 86: ...Figure 12 5 Transmission Motor Brake Assembly R6879 86...

Page 89: ...NOTES 89...

Page 90: ...Figure 12 7 Frame R6881 90...

Page 92: ...Figure 12 8 Load Wheels R6882 92...

Page 94: ...Figure 12 9 Elevation System Telescopic R6883 94...

Page 96: ...Figure 12 10 Elevation System TRIMAST R6884 96...

Page 98: ...Figure 12 11 Lift Carriage R6815 98...

Page 101: ...NOTES 101...

Page 102: ...Figure 12 13 Hydraulic System R6665 102...

Page 104: ...Figure 12 14 Pump Motor R6886 104...

Page 107: ...NOTES 107...

Page 108: ...Figure 12 16 Hydraulic System TRIMAST R6888 108...

Page 110: ...Figure 12 17 Tilt Cylinder Mounting R6892 110...

Page 112: ...Figure 12 18 Lift Cylinder Telescopic R6889 112...

Page 114: ...Figure 12 19 Free Lift Cylinder TRIMAST R6890 114...

Page 116: ...Figure 12 20 Secondary Lift Cylinder TRIMAST R6891 116...

Page 118: ...Figure 12 21 Tilt Cylinder R6893 118...

Page 120: ...Figure 12 22 Electrical System R6894 120...

Page 123: ...NOTES 123...

Page 124: ...Figure 12 24 Drive Motor R6630 124...

Page 128: ...NOTES 128...

Page 129: ...129...