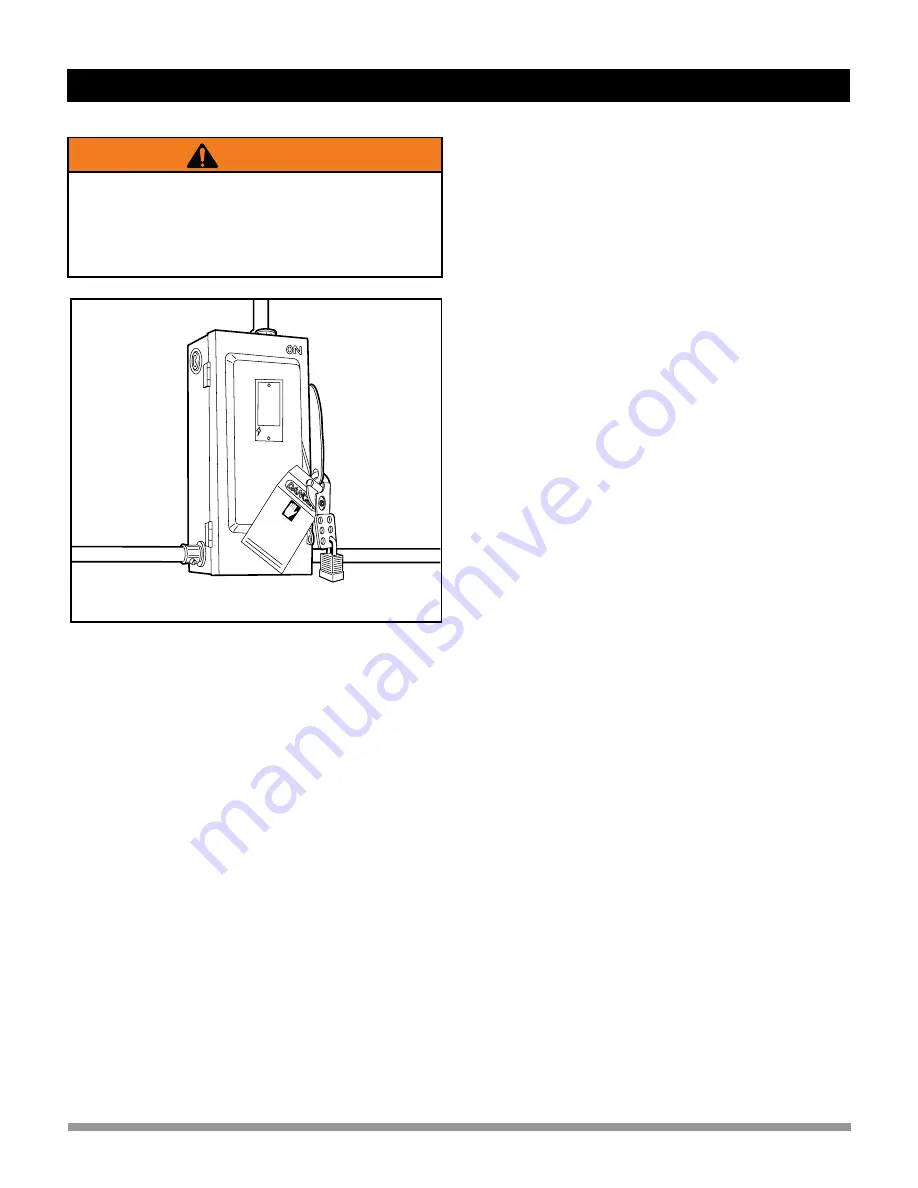

4. LOCKOUT / TAGOUT PROCEDURE and RULES

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XX

OPERAT

E

DO

NOT

ABOVE: APPROVED WAY TO LOCKOUT / TAGOUT

I

n accordance with the rules and regulations of the Occupational

Safety and Health Administration (OSHA), all affected

employees must be notified that the machine or equipment will

be shut down and locked out to perform repair or maintenance

work. The work area must be checked to ensure that all

personnel have been removed or safely repositioned. The

machine or equipment power supply shall be locked in the OFF

position or disconnected from the energy source. Blue Giant®

strongly recommends that only OSHA-approved lockout

devices be utilized.

The energy isolating device must bear a prominent warning tag

indicating that work is being done on the equipment and the

name of the authorized employee responsible for the lockout. It

is mandatory that tagout notices not be susceptible to

deterioration or illegibility due to weather conditions or exposure

to chemicals and moisture.

Always lockout and tagout any power source before

performing any work on any electrical

devices

or

electrical controls according to OSHA regulations

and approved local electrical codes.

!

U-SERIES AIRBAG DOCK LEVELER with SINGLE PUSH BUTTON CONTROLS

4