For Customer Service:

Please call 877-713-3189 (Toll Free),

or email: Support@fot-usa.com

3

• Never try to split logs larger than those indicated in the

machine. Do not use the log splitter for anything other

than splitting logs. Do not force log through splitter.

• Never use an extension cord that is not rated for outdoor

use. The cord should not be longer than 30 feet. The cord

should be of a heavy-duty construction (12-10 AWG).

• Check that the electric circuit is adequately protected and

corresponds with the power, voltage and frequency of

the motor. Check that there is a ground connection and

splitter. Prevent body contact with ground surfaces: pipes,

radiatiors, ranges, refrigerator enclosures, etc. Never open

do not touch the plug’s metal prongs when plugging in or

unplugging the log splitter.

• Do not remove jammed logs with your hands. If an object

becomes lodged in the ram, unplug electric motor before

attempting to remove the foreign object.

• Do not use the log splitter in areas where fumes from

explosion hazard.

• Disconnect power by unplugging power cord when not in

use, before making adjustments, changing parts, cleaning,

or working on the log splitter.

• Maintain and keep the log splitter clean for the best and

safest performance.

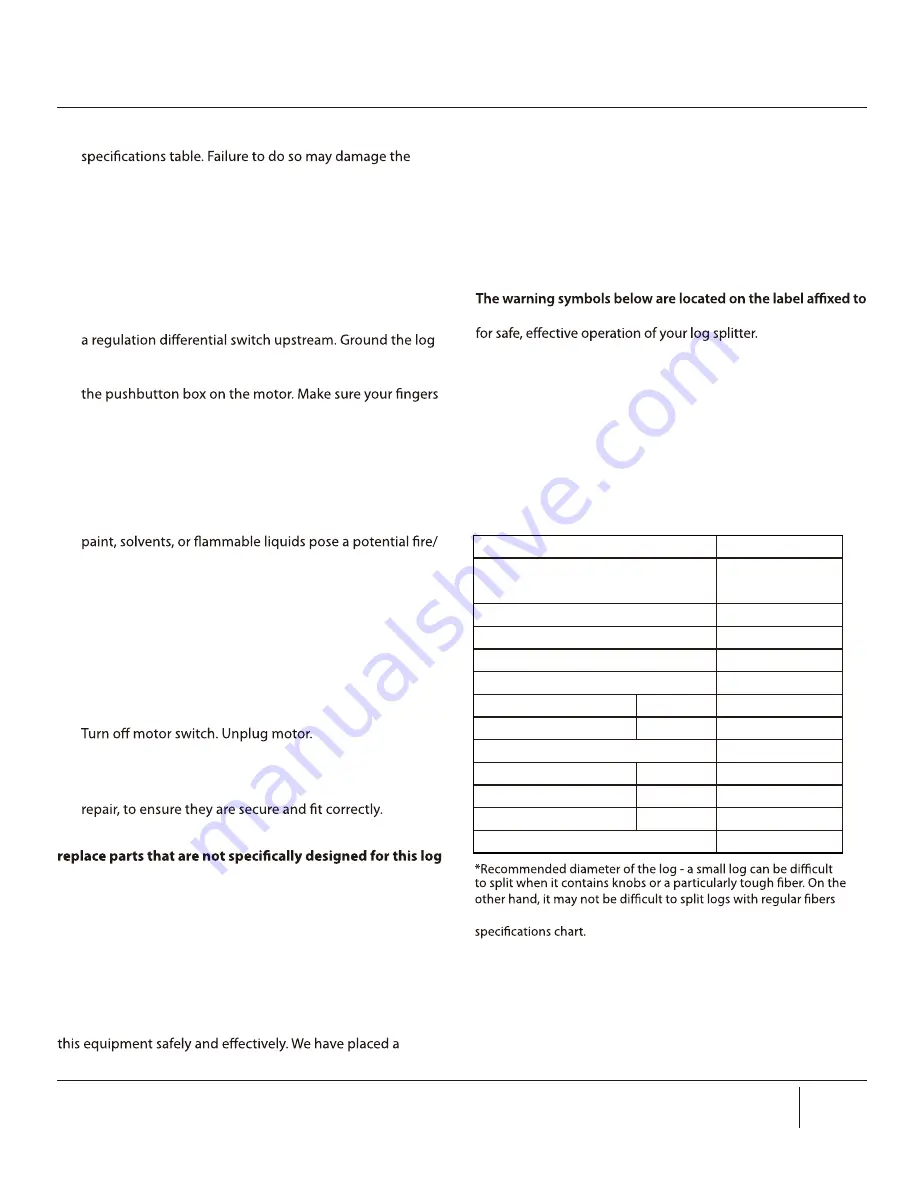

SAFETY DECAL

The Electric Log Splitter has been designed and manufactured

to provide you with the safety and reliability you would

expect from an industry leader in outdoor power equipment

manufacturing.

important information while you are operating the unit.

This important safety decal is illustrated below, and is shown

here to help familiarize you with the location and content of

the safety messages you will see as you perform normal log

splitting operations. Please review this decal now, and if you

have any questions regarding its meaning or complying with

these instructions, reread the complete safety instruction text

in this manual, or contact your local dealer.

the control lever guard.

Follow the safety instructions necessary

STEPS FOR WORKING ON ELECTRIC LOG SPLITTER

1.

2. Replace or repair the part on the log splitter.

3. Check all parts that were repaired, or removed during

NOTE: All repair parts must come from the factory. Never

splitter.

SPECIFICATIONS

33299

120V~60HZ

IP54

3550rpm

6 Ton

15.4"

2.36"

Log Capacity

Diameter

2"~9.8"

Length

20.5"

3.4L

Packing Size

Length

43.1"

Width

13"

Height

20.3"

101lb

Hydraulic Oil Capacity

Gross Weight

Model Number

Motor

Motor No-load Speed

Max. Splitting Force

Max. Cylinder Travel

Diameter of Cylinder

even if its diameter exceeds the maximum diameter described in the

ELECTRICAL REQUIREMENTS

Connect the main leads to a standard 110V ±10% electrical

supply which has protection devices under-voltage,

over-voltage, over-current, as well as a ground fault circuit

interrupter (GFCI) or a ground fault interrupter (GFI)

with a maximum residual current of 0.03A.

Reading this manual, and the safety instructions it contains,

will provide you with the necessary knowledge to operate

SPECIFICATIONS AND ELECTRICAL REQUIREMENTS

APPLICATION CONDITIONS

The 6-Ton Electric Log Splitter has been designed as a home use

model only. It is designed for operating at ambient temperatures

between 40° F. and 105° F. The log splitter can be stored or

transported under ambient temperatures between -10° F. and

130° F.

safety decal on the log splitter to remind you of some of the