SERVICE INFORMATION

IMPORTANT

IN CASE OF A SERVICE PROBLEM, DO NOT SEND

UNIT BACK TO RETAILER. Call 877-713-3189 (Toll Free),

or email: Support@fot-usa.com

In the event you experience trouble operating your log splitter,

follow the suggestions in the troubleshooting guide in this section.

The guide will help you pinpoint the causes of common problems

and identify remedies.

SERVICE, TROUBLESHOOTING AND REPAIR

TROUBLESHOOTING

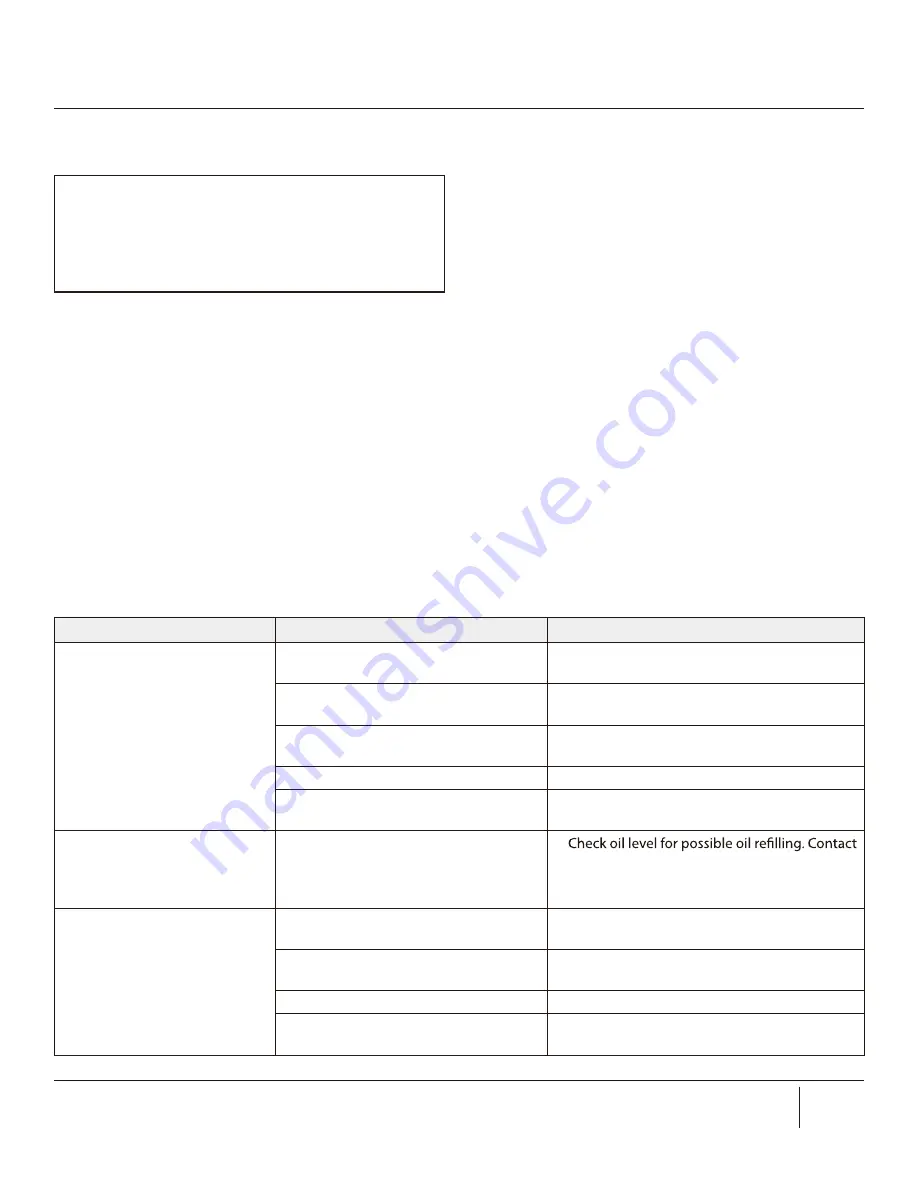

PROBLEM

POSSIBLE CAUSE

REMEDY/ACTION

Fails to split logs

1. Log is improperly positioned

1. Refer to Log Splitter Operation Section for log

loading

2. The size or hardness of the log exceeds

the capacity of the machine

2. Reduce the log size before splitting on the log

splitter

3. Wedge cutting edge is blunt

3. Refer to Sharpening Wedge Section to

sharpen the cutting edge

4. Oil leaks

4. Locate leak(s) and contact Customer Service

5. Unauthorized adjustment was made to

the maximum pressure limiting screw

5. Contact Customer Service

The log pusher moves with

a jerking motion, makes an

unfamiliar noise or vibrates

excessively

1. Lack of hydraulic oil and excessive air

in the hydraulic system

1.

Customer Service.

Oil leak occurs around cylinder

ram or from other points

1. Air sealed in hydraulic system while

operating

1. Loosen bleed screw 3-4 rotations before

operating the log splitter

2. Bleed screw is not tightened before

moving the log splitter

2. Tighten the bleed screw before moving the

log splitter

3. Oil drain bolt with dipstick is not tight

3. Tighten the oil drain bolt with dipstick

4. Hydraulic control valve assembly and/

or seal(s) worn

4. Contact Customer Service

For Customer Service:

Please call 877-713-3189 (Toll Free),

or email: Support@fot-usa.com

8