10

o

2) When satisfied with the fit, remove the ai-

leron and slide a small piece of waxed paper be-

tween the aileron torque rod and the trailing edge

of the wing. See photo # 15 below.

Photo # 15

The waxed paper will prevent epoxy from

gluing the torque rod to the trailing edge of

the wing.

o

3) Mix up a small amount of Kwik Bond 30

Minute Epoxy. Apply a thin layer of epoxy to the

aileron torque rod. Also use a toothpick and pack

epoxy into the predrilled hole in the aileron.

o

4) Slide the aileron and it's hinges into their

precut hinge slots in the trailing edge of the wing,

making sure the torque rod is firmly seated in the

precut hole in the leading edge of the aileron. With

the aileron tight against the wing, rotate the aile-

ron down about 45º. Apply six drops of Kwik

Bond Thin C/A to the exposed area of each hinge.

Allow the glue to cure for about ten minutes.

Once cured, the aileron may be stiff and difficult

to move. This is normal. Gently move the aileron

up and down about five to ten times to free it up.

o

5) Repeat steps # 1 - # 4 for the second

aileron.

HINGE THE ELEVATOR

o

6) The C/A hinges have already been glued

into the elevator. Slide the elevator and it's hinges

into their precut hinge slots in the trailing edge of

the horizontal stabilizer. Slide the elevator in until

it is tight against the trailing edge of the stabi-

lizer. The maximum hinge gap should be no more

than 1/32”. See photo # 16 below.

Photo # 16

o

7) With the elevator tight against the stabi-

lizer, rotate the elevator down about 45º. Apply

six drops of Kwik Bond Thin C/A to the exposed

area of each hinge. Allow the glue to cure for

about ten minutes. Once cured, the elevator may

be stiff and difficult to move. This is normal.

Gently move the elevator up and down about five

to ten times to free it up.

INSTALL THE TAIL WHEEL WIRE

o

8) Using a ruler and a pen, measure up 3/4”

from the bottom of the rudder, at the leading edge,

and place a mark.

o

9) Using a 3/32” drill bit, drill a hole into the

rudder at the mark made. Using a modeling knife,

cut a groove from the hole, down to the bottom of

the rudder. Make the hole deep enough for the tail

wheel wire to set flush in. See figure # 4 below.

Figure # 4

o

10) Mix up a small amount of Kwik Bond 5

Minute Epoxy. Apply the epoxy to only those

parts of the tail wheel wire that will be glued to

the rudder. Pack epoxy into the hole you drilled

in the leading edge of the rudder also.

o

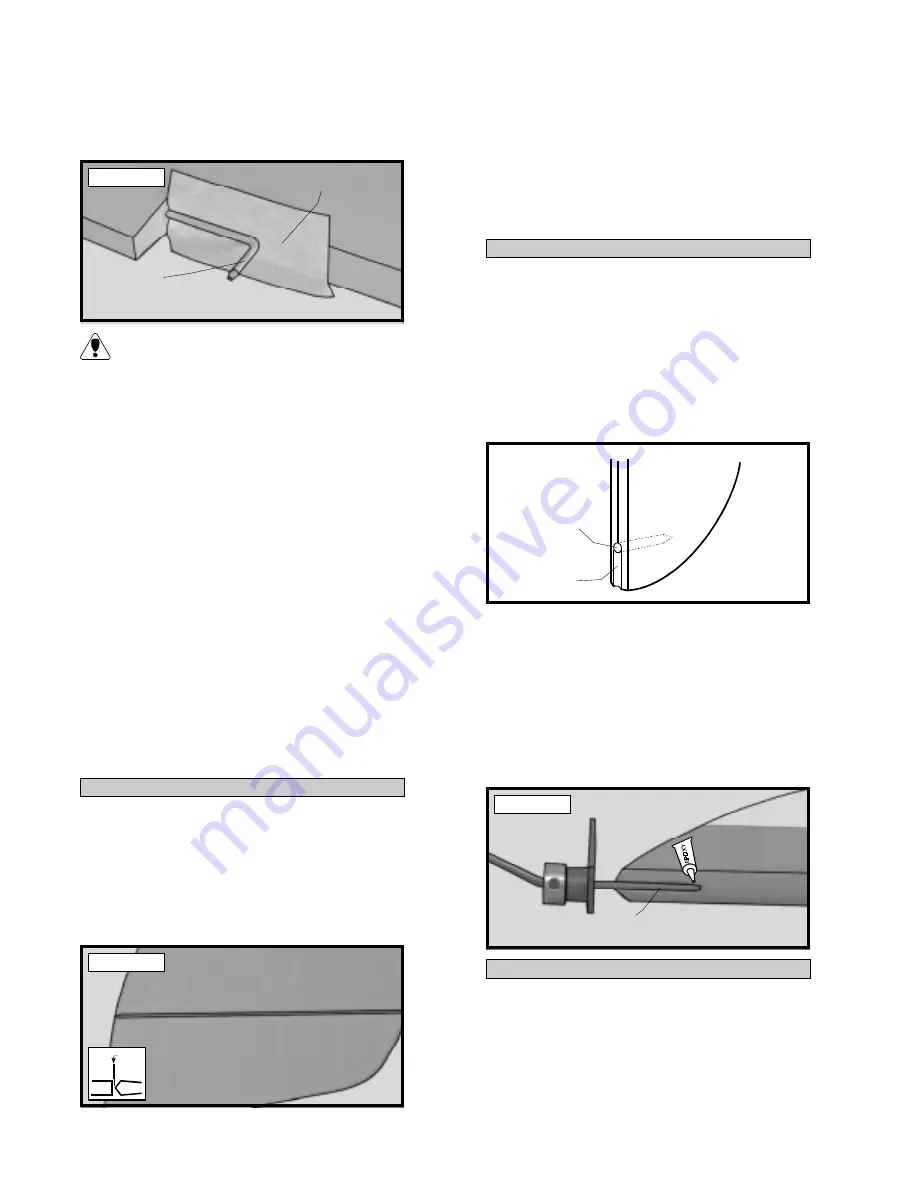

11) Insert the tail wheel wire into the rudder.

Clean up any excess epoxy using a paper towel and

rubbing alcohol. See photo # 17 below.

Photo # 17

HINGE THE RUDDER

o

12) The C/A hinges have already been

glued into the rudder. Slide the rudder and it's

hinges into their precut hinge slots in the trailing

edge of the vertical stabilizer. Slide the rudder

in until it is tight against the trailing edge of the

stabilizer. The maximum hinge gap should be no

more than 1/32”.

TORQUE ROD

WAXED PAPER

1/32”

ELEVATOR

STABILIZER

DRILL

HOLE

CUT

GROOVE

TAIL WHEEL

WIRE