15

o

10) Secure the fuel tank in place using sev-

eral pieces of foam rubber. Seal any gaps be-

tween the stopper assembly and the firewall us-

ing silicon sealer. Be careful not to get any sealer

inside the aluminum tubing.

PARTS REQUIRED

THROTTLE LINKAGE

INSTALLING THE THROTTLE LINKAGE

o

{1} 1.5mm x 300mm Wire Threaded One End

o

1) Locate and drill a 3/32” hole through the

firewall for the throttle pushrod wire to pass

through (you may need to temporarily remove the

engine). The hole should be level with the throttle

arm, but may need to be moved slightly to clear

the fuel tank depending on the engine used.

o

2) Slide the plain end of the pushrod wire

through the hole and into the fuselage. Remove

the throttle arm from the carburetor and attach

the Z-bend to the outer hole in the arm.

o

3) Reattach the throttle arm to the carbure-

tor and use a pair of pliers to make any necessary

bends in the wire so it does not bind when the

carburetor is moved from idle to the full throttle

position. See photo # 30 below.

Photo # 30

PARTS REQUIRED

SERVO INSTALLATION

INSTALLING THE FUSELAGE SERVO TRAY

o

{1} Aileron Servo Tray (W-39)

o

{1} Fuselage Servo Tray (D-47)

o

{4} 3mm x 12mm Wood Screws

o

1) Install the rubber grommets and brass

collets onto three servos. Test fit the servos into

the precut servo holes in the servo tray.

Because the size of servos differ, you may

need to adjust the size of the precut open-

ings. You may also need to use a modeling knife

and cut a groove to allow room for the servo wires.

o

2) Remove the servos from the servo tray.

Using a ruler and a pen, locate and mark the po-

sition of the four servo tray mounting holes on the

top of the tray. Two holes are located 3/8” back

from the front edge of the tray and 1/8” in from

each side. Two holes are also located 3/8” for-

ward of the rear edge and 1/8” in from the sides.

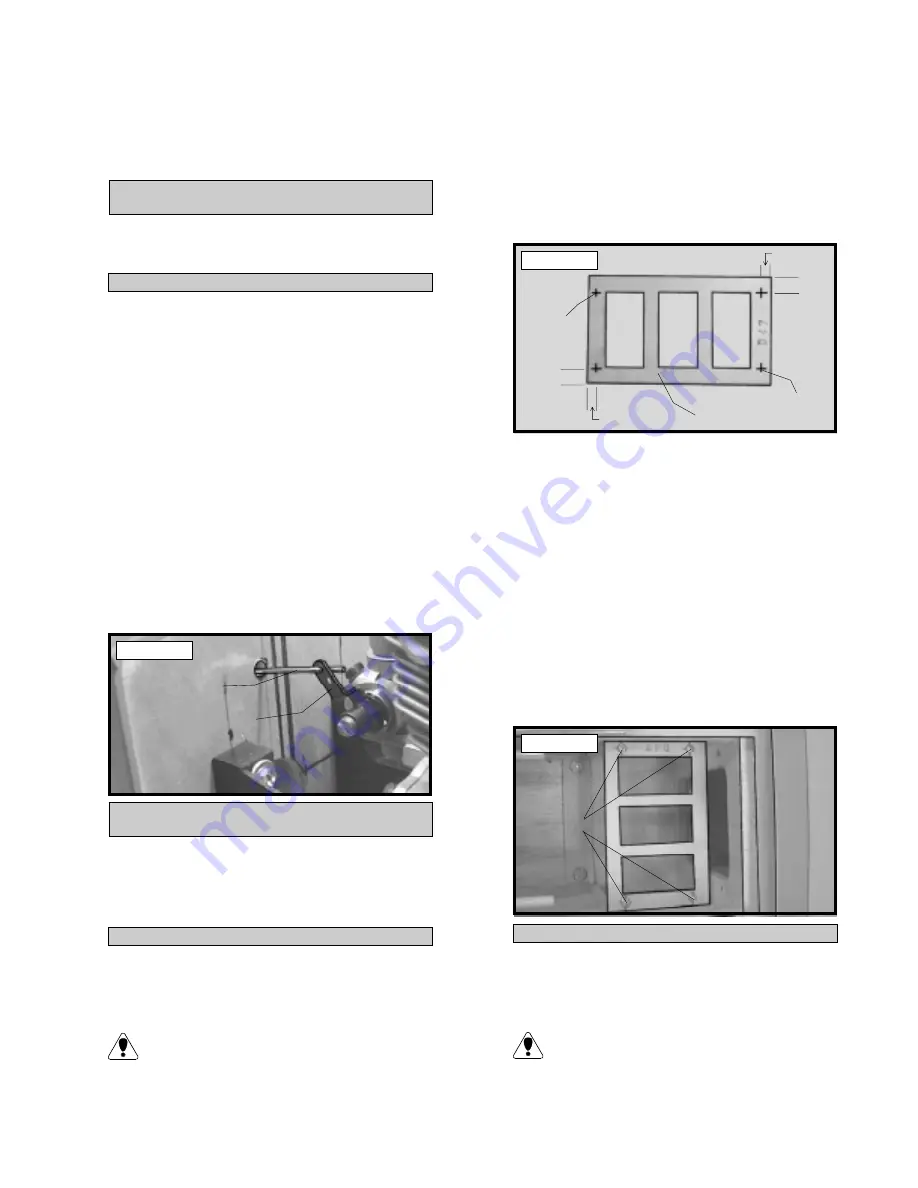

See photo # 31 below.

Photo # 31

o

3) Using a 1/16” drill bit, drill pilot holes

through the servo tray at the four mounting hole

locations.

o

4) Set the servo tray onto the preinstalled

support rails just to the rear of the forward bulk-

head. The front of the tray should be pushed

firmly up against the forward bulkhead.

o

5) Using a 1/16” drill bit and the pilot holes

in the servo tray as a guide, drill four holes through

the support rails.

o

6) Secure the tray in place using four 3mm x

12mm wood screws. See photo # 32 below.

Photo # 32

INSTALLING THE AILERON SERVO TRAY

o

7) Install the rubber grommets and brass

collets onto the fourth servo. Test fit the servo

into the aileron servo tray (W-39).

Because the size of servos differ, you may

need to adjust the size of the precut open-

ings. You may also need to use a modeling knife

and cut a groove to allow room for the servo wire.

PUSHROD

WIRE

THROTTLE

ARM

3/8”

1/8”

3/8”

1/8”

MAKE

MARKS

MAKE

MARKS

SERVO TRAY

3mm x 12mm

WOOD

SCREWS