16

o

8) Place the servo tray, with the aileron servo,

into the precut opening in the bottom of the wing.

The servo should be orientated with the output shaft

towards the trailing edge of the wing.

o

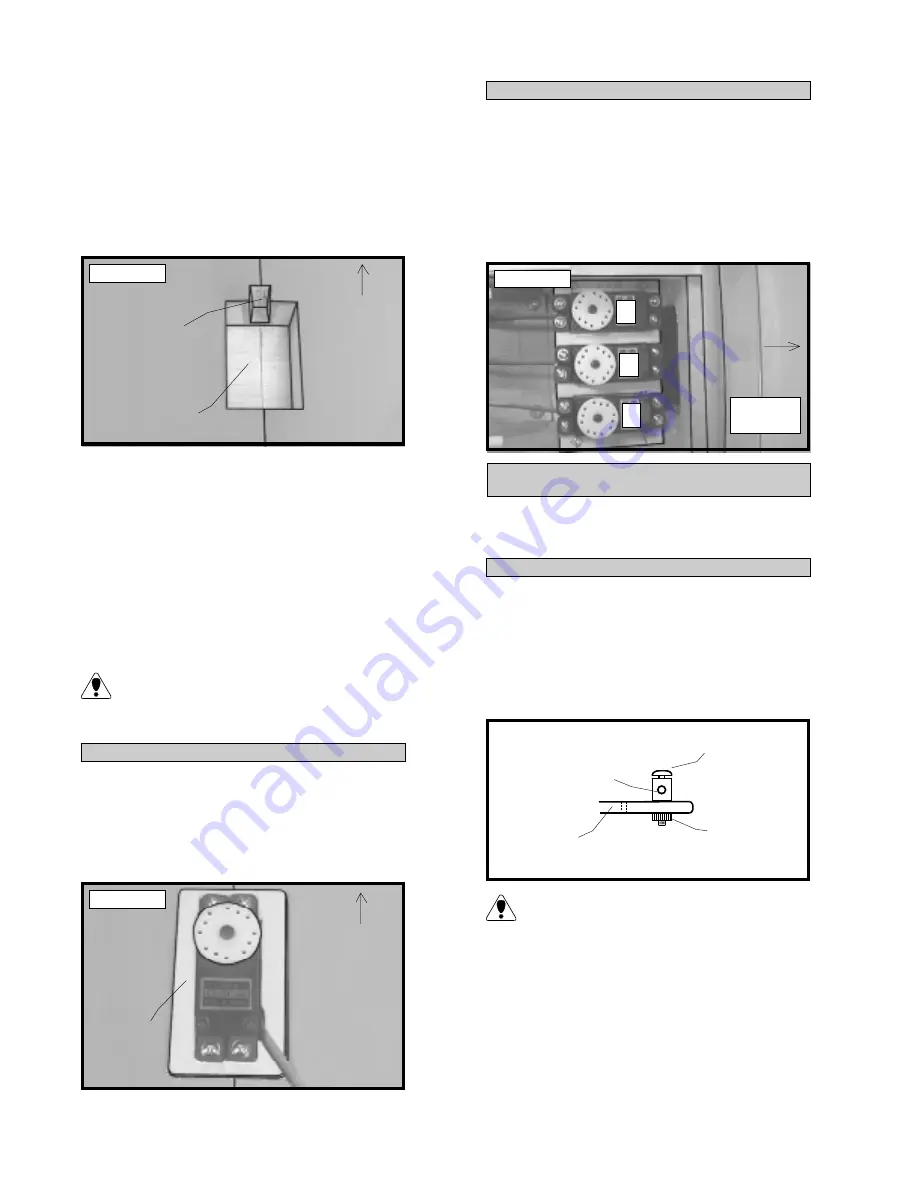

9) Remove the servo tray and using a model-

ing knife, carefully cut a notch in the wing to allow

room for the servo wire. See photo # 33 below.

Photo # 33

o

10) Set the tray back in place and trace

around it using a pen. Remove the tray and using

a modeling knife, remove the covering from just

inside the lines.

o

11) Mix a small amount of Kwik Bond 5

Minute Epoxy and glue the tray in place. Be care-

ful not to get any epoxy on the servo. Allow the

epoxy to cure completely.

There will be some gaps around the outer

edges of the tray. Use enough epoxy to com-

pletely fill any gaps between the tray and wing.

INSTALLING THE AILERON SERVO

o

12) Install the servo using the wood screws

provided with your radio system. Drill 1/16” pi-

lot holes through the tray before installing the

screws. This will help prevent the wood from

splitting. See photo # 34 below.

Photo # 34

INSTALLING THE FUSELAGE SERVOS

o

13) Install the three fuselage servos using

the wood screws provided with your radio sys-

tem. Drill 1/16” pilot holes through the tray be-

fore installing the screws. This will help prevent

the wood from splitting. Install the servos with

the output shafts in the orientation shown. See

photo # 35 below.

Photo # 35

PARTS REQUIRED

THROTTLE CONNECTOR

INSTALLING THE THROTTLE CONNECTOR

o

{1} Adjustable Servo Connector Assembly

o

1) Install one adjustable servo connector

through the second hole out from the center of one

servo arm. You may have to enlarge the hole in the

servo arm to accommodate the servo connector.

Remove the excess material from the servo arm

using wire cutters. See figure # 5 below.

Figure # 5

After installing the adjustable servo connec-

tor apply a small drop of Kwik Bond Thin

C/A to the nut. This will prevent the connector

from loosening during flight.

o

2) Turn on the radio system. Check to en-

sure that the throttle servo output shaft is moving

in the correct direction.

CUT NOTCH

PRECUT SERVO

OPENING

SERVO TRAY

TRAILING

EDGE

TRAILING

EDGE

T

R

E

E = ELEVATOR

T = THROTTLE

R = RUDDER

SERVO ARM

NUT

SET SCREW

CONNECTOR

FRONT