18

o

8) Use a couple of pieces of masking tape

to hold the rudder in neutral.

o

9) Locate a long servo arm. Using wire cut-

ters, remove all but one of the arms. Install the

Z-bend in the 1.5mm x 50mm wire into the outer

hole in the servo arm.

o

10) With the rudder and rudder servo in neu-

tral, install the servo arm onto the servo. The arm

should be positioned perpendicular to the fuse-

lage side and point out towards the side.

o

11) Using a pen, place a mark on the nylon

rudder pushrod where the tip of the threaded wire

overlaps it. Use a modeling knife and cut off the

nylon pushrod 5/16” in front of the mark. This

will leave enough space so the threaded wire can

thread into the pushrod at least 5/16”.

o

12) Remove the servo arm from the servo

and thread the wire into the pushrod. You can

thread it in further or back it out to achieve the

correct length.

o

13) When satisfied with the alignment, install

the servo arm set screw and remove the masking

tape from the rudder. See photo # 38 below.

Photo # 38

PARTS REQUIRED

ELEVATOR PUSHROD

INSTALLING THE ELEVATOR CONTROL HORN

o

{1} Nylon Control Horn w/Nylon Back Plate

o

{2} 2mm x 15mm Machine Screws

o

{1} 990mm Nylon Pushrod

o

{1} 1.5mm x 45mm Wire Threaded Both Ends

o

{1} 1.5mm x 50mm Threaded Wire w/Z-Bend

o

{1} Nylon Clevis w/1.5mm I.D. Hole

o

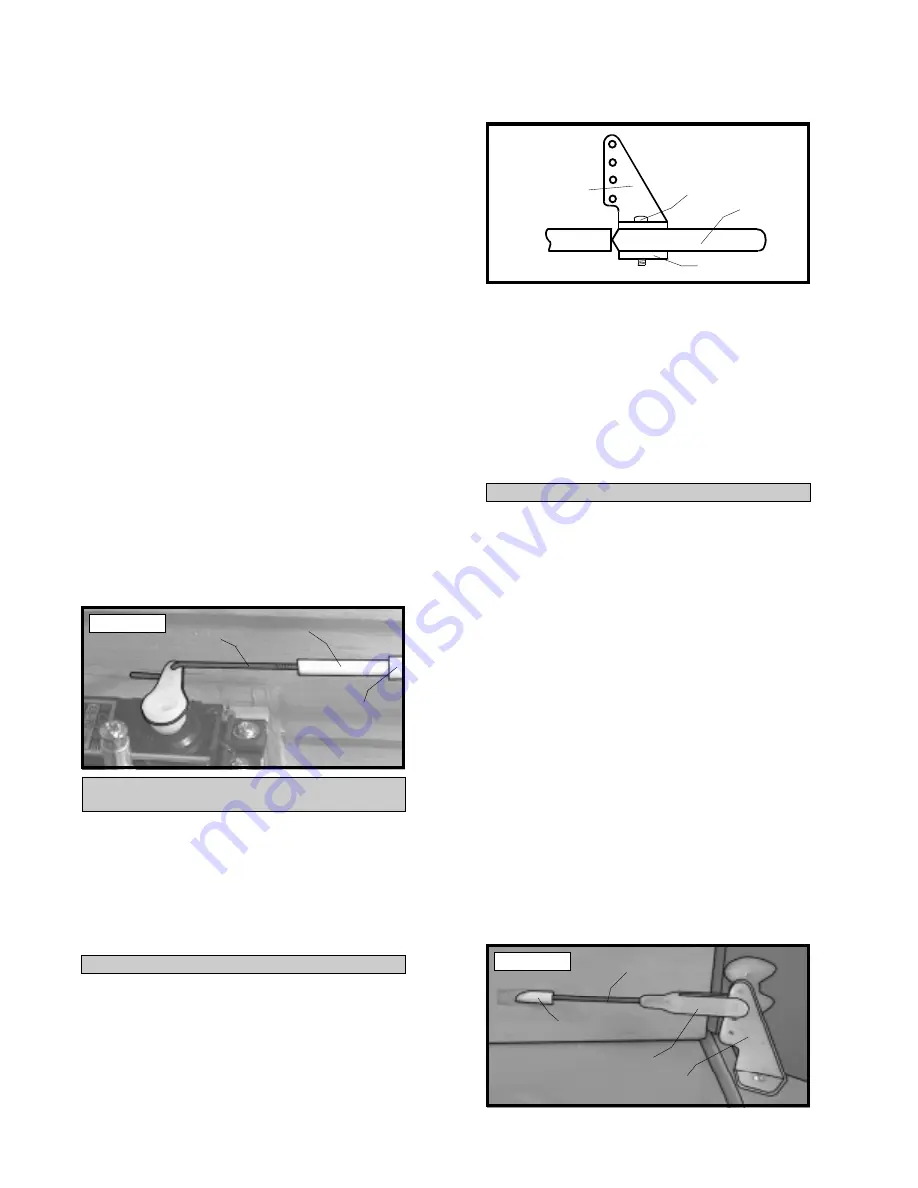

1) The centerline of the elevator control

horn is located on the bottom right side of the

elevator, 3/4” out from the fuselage side. Posi-

tion the control horn so the clevis attachment

holes are directly in-line with the hinge line. The

control horn should also be angled slightly

Figure # 7

o

2) When satisfied with the alignment, use a

3/32” drill bit and the control horn as a guide and

drill the mounting holes through the elevator.

o

3) Mount the control horn to the elevator

by inserting the 2mm x 15mm machine screws

through the control horn mounting base, through

the elevator and into the backplate. Tighten the

screws, but do not overtighten them. You do not

want to crush the wood.

o

4) Thread the 1.5mm x 45mm threaded wire

into one end of the second nylon pushrod. For

safety, thread the wire no less than 5/16” into the

pushrod.

o

5) Thread the nylon clevis onto the oppo-

site end of the 1.5mm x 45mm threaded wire. It

should be threaded no less than 5/16” onto the

wire also.

o

6) Using a modeling knife remove the cov-

ering from over the elevator pushrod exit slot.

Looking from the back of the airplane, the slot is

located on the right side of the fuselage, 1-7/8”

forward of the rudder hinge line and 1/2” below

the horizontal stabilizer.

o

7) Insert the plain end of the nylon pushrod

into the fuselage from the back. Snap the clevis

onto the elevator control horn. Move the eleva-

tor up and down to ensure there is no binding.

See photo # 39 below.

INSTALLING THE ELEVATOR PUSHROD

Photo # 39

PUSHROD

WIRE

NYLON

PUSHROD

PUSHROD

TUBE

towards the pushrod exit in the fuselage side. See

figure # 7 below.

NYLON

CLEVIS

PUSHROD

WIRE

NYLON

PUSHROD

CONTROL

HORN

CONTROL HORN

BACKPLATE

MACHINE

SCREW

ELEVATOR