24

o

C) The ailerons should move 3/8” up

and 3/8” down from center. To adjust the amount

of aileron throw, first move the pushrods on the

servo arm. Move the pushrods toward the cen-

ter of the servo for less movement. Move the

pushrods farther away from the center of the

servo for more movement. If enough movement

cannot be achieved in this manner, thread the

adjustable torque rod horns farther down the

torque rods, toward the wing. It is important

that both ailerons move the same amount, both

up and down.

o

D) Once the control throws and move-

ments are set, tubing must be added to the clev-

ises to ensure they do not release in the air. A

length of clear tubing was provided in the kit for

this. Cut it into the 1/4” pieces and slip one piece

over each clevis.

o

1) Completely charge your transmitter and

receiver batteries before your first day of flying.

o

2) Check every bolt and every glue joint in

the Blue Max to ensure everything is tight and

well bonded. This should include all of the con-

trol surface hinges as well.

o

3) Double check the balance of the airplane.

Do this with the fuel tank empty.

o

4) Check the control surfaces. All should

move in the correct direction and not bind.

o

5) Check the receiver antenna. It should be

fully extended and not coiled up inside the fuselage.

PREFLIGHT CHECK

BASICS OF FLIGHT

To begin you should know how your Blue Max

operates. First, there are four forces operating

on a flying aircraft; Lift, Weight, Thrust and Drag.

The engine will create thrust to overcome the drag.

In times when the engine is off, gravity pulling the

plane down can act as thrust (how gliders work).

The wing flies through the air as a result of the

thrust and causes lift to overcome the weight of

the aircraft.

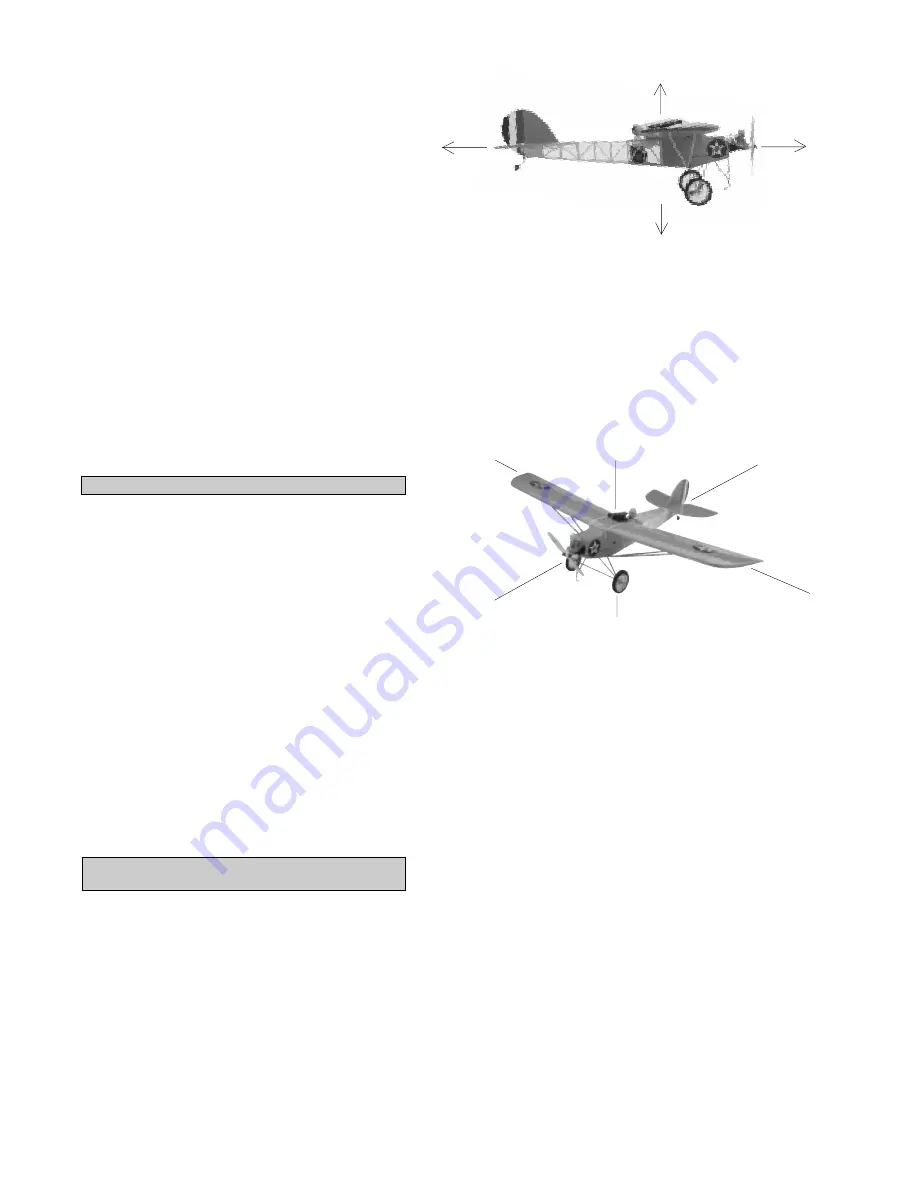

Controlling the Blue Max

Flying is three dimensional, therefore, all aircraft

operate on three axis: roll, yaw and pitch. Roll is

the wing tips raising and lowering. Yaw is the

nose moving from right to left. Pitch is seen as

the nose moving up and down. Maintaining flight

is the act of overcoming weight and drag with lift

and thrust while properly controlling all three axis.

Choosing the Blue Max greatly simplifies these

activities. First, it takes very little thrust to over-

come the drag. So much so that the Blue Max

glides with no power at all.

Second, the wing is a high lift design that easily

overcomes the weight which means that the Blue

Max can fly very slowly.

Controlling the plane

If you have never controlled any vehicle by ra-

dio control, then this step can be especially im-

portant. Some of the basic coordination can be

learned on the ground by simply practicing taxi-

ing the aircraft. First, remove the wing and cover

the open area of the fuselage where the wing

would normally go with a thin piece of card-

board. This will protect the radio equipment

from engine exhaust.

ROLL

AXIS

PITCH AXIS

YAW AXIS

LIFT

DRAG

THRUST

WEIGHT