8

o

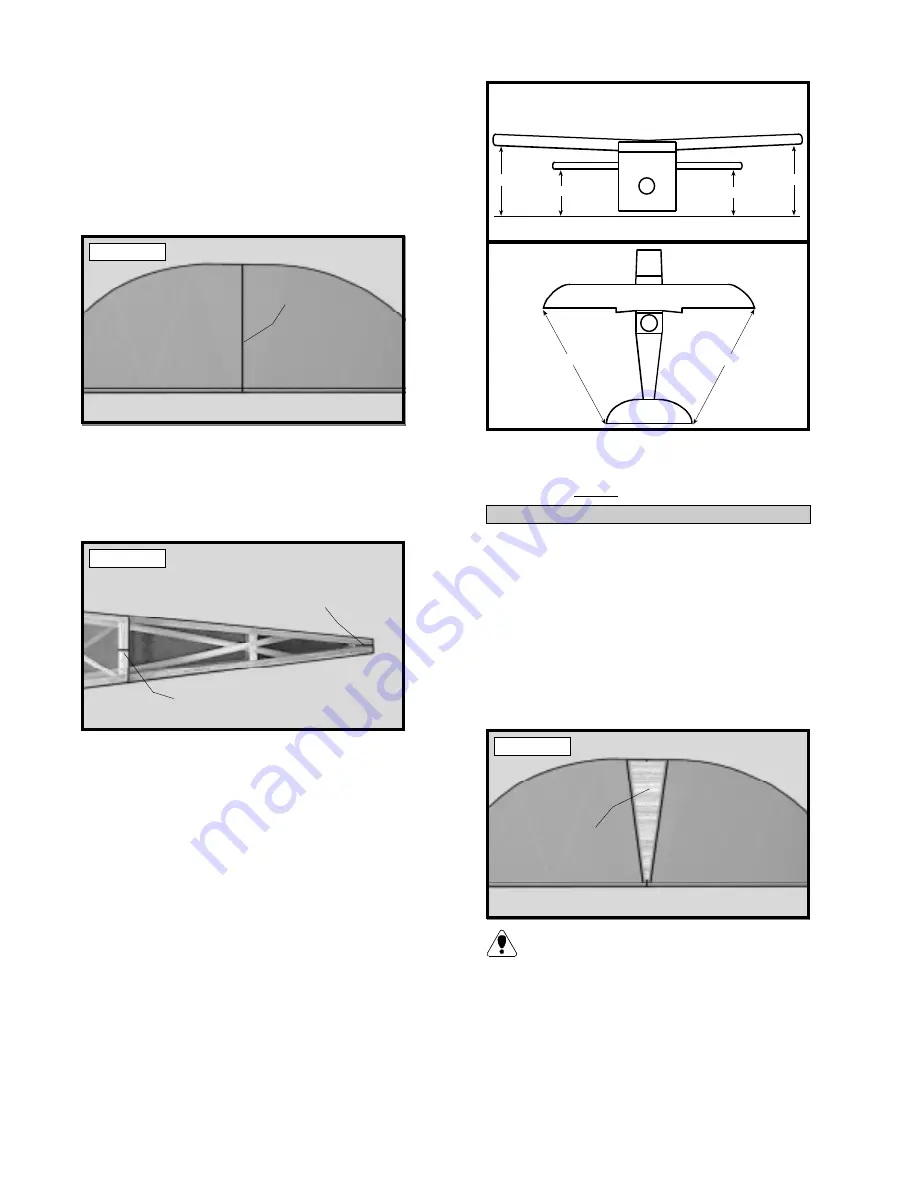

3) Using a ruler and a pen, locate and place

a mark at the centerline of the fuselage at the front

and rear of the stabilizer mounting platform. These

marks will be used to line up the stabilizer with

the fuselage. See photo # 12 below.

o

2) Using a ruler and a pen, locate and mark

the centerline of the horizontal stabilizer at the

trailing edge and place a mark. Use a triangle

and extend this mark, from back to front, across

the bottom of the stabilizer. Also place center-

line marks on the top of the stabilizer at the leading

and trailing edges only. See photo # 11 below.

Photo # 11

Photo # 12

o

4) Attach the wing to the fuselage and re-

move both ailerons. Set the horizontal stabilizer

onto the stabilizer mounting platform on the fuse-

lage. Align the centerline marks on top of the

stabilizer with the centerline marks at the front

and rear of the stabilizer mounting platform. When

the marks are aligned hold the stabilizer in posi-

tion using a couple of T-pins. Align the horizontal

stabilizer with the wing. When viewed from the

rear, the horizontal stabilizer should be level with

the wing. If it is not level, use sandpaper and

sand down the high side of the stabilizer mount-

ing platform until the proper alignment is achieved.

The tips of the stabilizer should also be equal dis-

tance from the tips of the wing. See figures # 1

and # 2 at top right.

Figure # 1

Figure # 2

o

5) When you are satisfied with the alignment,

hold the stabilizer in place with T- pins or mask-

ing tape, but do not glue at this time.

o

6) With the stabilizer held firmly in place, use

a pen and draw a line on the stabilizer where it

and the fuselage sides meet. Do this on both the

right and left sides on the bottom of the stabilizer.

o

7) Remove the stabilizer. Using the lines you

just drew as a guide, carefully remove the covering

from between them, using a modeling knife. See

photo # 13 below.

MOUNTING THE HORIZONTAL STABILIZER

Photo # 13

When cutting through the covering to re-

move it, cut with only enough pressure to

only cut through the covering itself. Cutting into

the balsa structure may weaken it and cause pos-

sible failure in flight.

DRAW

CENTERLINE

DRAW

CENTERLINE

DRAW

CENTERLINE

A

B

A1

B1

C

C1

REMOVE

COVERING