Outdoor Patio Heater Model No. GWU9209W / UB093-003-73-19

Contact 1.800.762.1142 for assistance. Do not return to place of purchase.

Have a question or are having problems visit www.bluerhino.com or call 1.800.762.1142.

Note:

the burner may be noisy when initially turned on. To eliminate excessive noise from

the burner, turn the control knob to the pilot position. Then, turn the knob to the level of heat

desired.

When heater is ON:

Emitter screen will become bright red due to intense

heat. The color is more visible at night.

Burner will display tongues of blue and yellow flame.

These flames should not be yellow or produce thick

black smoke, indicating an obstruction of airflow

through the burners. The flame should be blue with

straight yellow tops.

If excessive yellow flame is detected, turn off heater

and visit www.bluerhino.com or call 1.800.762.1142.

Re-lighting

Note:

For your safety, control knob cannot be turned “OFF” without first depressing control

knob in PILOT position and then rotating it to “OFF”.

1. Turn control knob to “OFF”.

2. Wait at least 5 minutes, to let gas dissipate, before attempting to relight pilot.

3. Repeat the “Lighting” procedure.

Shut Down

1. Turn control knob clockwise to pilot. (Normally, burner will make a slight popping sound when

extinguished.) Burner will extinguish but pilot will remain “ON”.

2. To extinguish pilot, depress control knob and continue to turn it clockwise to “OFF”.

3. Turn tank valve to “CLOSED” and disconnect regulator when heater is not in use.

Note: After use, some discoloration of the emitter screen is normal.

Cleaning and Care

CAUTION: All cleaning and maintenance should be done when patio

heater is cool and with the fuel supply disconnected.

CAUTION: DO NOT clean any patio heater part in a self cleaning oven.

The extreme heat will damage the finish.

Notices

1. Abrasive cleaners will damage this product.

2. Never use oven cleaner to clean any part of heater.

3. Do not clean any heater part in a self cleaning oven. The extreme heat will damage the

finish.

4. More frequent cleaning may be required as necessary. It is imperative that control

compartment, burners and circulating air passageways of the heater be kept clean.

5. Spiders and insects can create a dangerous condition that may damage heater or

make it unsafe. Keep burner area clean of all spiders, webs, or insects. Clean burner

holes by using a heavy-duty pipe cleaner. Compressed air may help clear away smaller

particles.

6. Inspect heater before each use.

7. Have heater inspected annually and repairs should be made by a qualified service

person.

8. Check heater immediately if any of the following conditions exist:

a. The smell of gas in conjunction with extreme yellow tipping of burner flames.

b. Heater does not reach proper temperature.

Note: At temperatures less than 40ºF, heat output will be reduced.

c. Heater’s glow is excessively uneven

d. Burner makes popping noises during use.

Note: A slight pop is normal when burner is extinguished.

9. Carbon deposits may create a fire hazard. Keep dome and emitter clean at all times.

10. Do not clean heater with combustible or corrosive cleaners. Use warm, soapy water.

11. Do not paint engine, engine access panel or dome.

12. This heater should be thoroughly cleaned on a regular basis.

13. After a period of storage and/or nonuse, check for leaks, burner obstructions and

inspect for any abrasion, wear, cuts to the hose.

Cleaning Surfaces

1. Wipe surfaces clean with mild dishwashing detergent or baking soda.

2. For stubborn surfaces use a citrus based degreaser and a nylon scrubbing brush.

3. Rinse clean with water.

Note:

While cleaning your unit, be sure to keep the area around the burner and pilot assembly

dry at all times. Do not submerge the control valve assembly. If the gas control is submerged in

water, do NOT use it. It must be replaced.

Operating Instructions

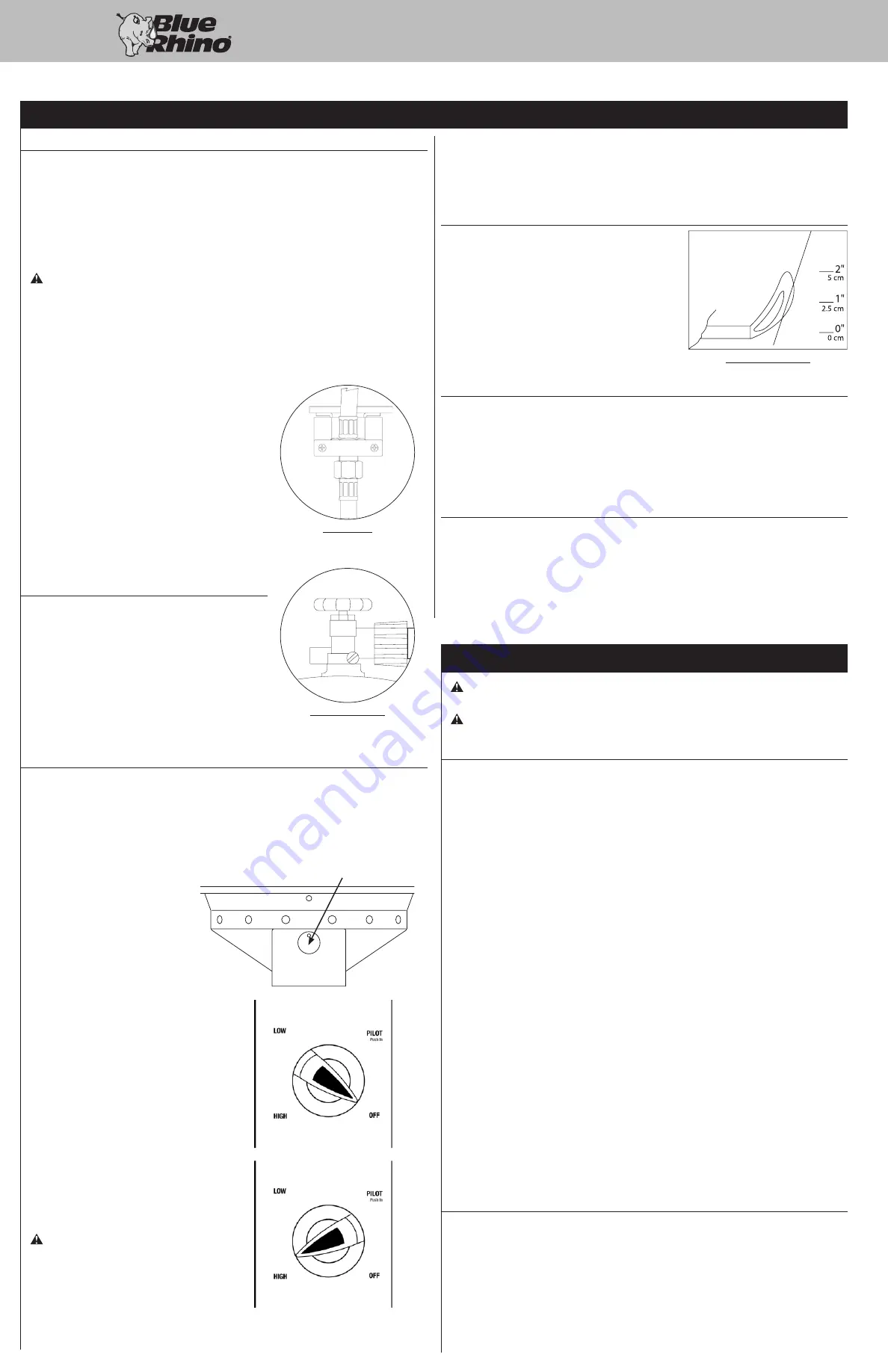

Checking for Leaks

Burner Connections

1. Make sure the regulator valve and hose connections are securely fastened to the burner and

the tank.

2. If your unit was assembled for you, visually check the connection between the burner pipe

and orifice. Make sure the burner pipe fits over the orifice.

WARNING: Failure to inspect this connection or follow these

instructions could cause a fire or an explosion which can cause death,

serious bodily injury, or damage to property.

3. If the burner pipe does not rest flush to the orifice, please contact 1.800.762.1142 for

assistance.

Tank/Gas Line Connection

1. Make 2-3 oz. of leak solution by mixing one part liquid

dishwashing soap with three parts water.

2. Make sure control knobs are “OFF”.

3. Turn LP gas tank valve to “OPEN”.

4. Spoon leak check solution at all “X” locations

a. If any bubbles appear turn LP gas tank valve to

“CLOSED”, reconnect and re-test.

b. If you continue to see bubbles after several

attempts, turn LP gas tank valve to “CLOSED”

and disconnect LP gas tank and contact

1.800.762.1142 for assistance.

b. If no bubbles appear after one minute turn LP gas tank valve to “CLOSED”, wipe away

solution and proceed.

Before Lighting

1. Heater should be thoroughly inspected before each

use, and by a qualified service person at least

annually.

2. If relighting a hot heater, always wait at least 5

minutes.

3. Inspect the hose assembly for evidence of excessive

abrasion, cuts, or wear. Suspected areas should be

leak tested. If the hose leaks, it must be replaced prior

to operation. Only use the replacement hose assembly specified by manufacturer.

Lighting

Note:

this heater is equipped with a pilot light that allows for safer startups and shutdowns.

Pilot must be lit before main burner can be started.

1. Control knob must be in the “OFF” position.

2. Turn LP gas tank valve to “OPEN”.

3. Open viewing hole by sliding cover to

either side.

4. Push control knob in and rotate to

“PILOT” position.

Note:

for initial start or after any tank

change, hold control knob in for 2

minutes to purge air from gas lines

before proceeding.

5. Push igniter button once. Pilot light

flame will appear and be visible

through viewing hole.

6. Release control knob after 30 seconds.

Pilot light will remain lit.

7. If ignition does not occur, turn control knob

“OFF”, wait 5 minutes, and repeat lighting

procedure.

8. Turn control knob to “HIGH”. Main burner

will light immediately. Flame is visible

through viewing hole. If not, turn control

knob “OFF”, wait 5 minutes, and repeat

lighting procedure.

9. If for some reason your ignitor fails to

deliver a spark, your heater can be started

by inserting a lit match through the pilot

view hole while pushing the control knob

in while in the “PILOT” position.

WARNING: Be careful when

attempting to manually ignite

this heater. Holding in the

control know for more than 10

seconds before igniting the gas

will cause a ball of flame upon

ignition.

LP Gas Line

X

LP Gas Tank Valve

X

X

X

X

X

View Hole

Proper flame height.

Control Knob