9

Installation Requirements

NOTE:

•

It is most important that this appliance is installed correctly and that operation is correct

before use. Installation shall comply with local gas, health and safety requirements.

•

This appliance shall be installed with sufficient ventilation to prevent the occurrence of

unacceptable concentrations of health harmful substances in the room, the appliance is

installed in.

Blue Seal Gas Griddles are designed to provide years of satisfactory service and correct installation is

essential to achieve the best performance, efficiency and trouble-free operation.

This appliance must be installed in accordance with National installation codes and in addition, in

accordance with relevant National / Local codes covering gas and fire safety.

Australia:

- AS5601

- Gas Installations.

New Zealand:

- NZS5261

- Gas Installation.

United Kingdom:

- Gas Safety (Installation & Use) Regulations 1998.

- BS6173

- Installation of Catering Appliances.

- BS5440

- 1 & 2 Installation Flueing & Ventilation.

Ireland:

- IS 820

- Non - Domestic Gas Installations.

Installations must be carried out by qualified persons only. Failure to install equipment to the

relevant codes and manufacturer’s specifications shown in this section will void the warranty.

Components having adjustments protected (e.g. paint sealed) by the manufacturer are only

to be adjusted by an authorised service agent. They are not to be adjusted by the installation

person.

Unpacking

•

Remove all packaging and transit protection from the appliance including all protective plastic

coating from the exterior stainless steel panels.

•

Check equipment and parts for damage. Report any damage immediately to the carrier and

distributor.

•

Ensure that the 4 adjustable feet are fitted with the protruding centre screw.

•

Report any deficiencies to the distributor who supplied the appliance.

•

Check that the available gas supply is correct to that shown on the rating plate located behind the

front control panel and on the inner face of the right hand panel.

Location

1.

Installation must allow for a sufficient flow of fresh air for the combustion air supply.

2.

Installation must include adequate ventilation means, to prevent dangerous build up of combustion

products.

3.

Any gas burning appliance requires adequate clearance and ventilation for optimum and trouble-free

operation. The minimum installation clearances shown below are to be adhered to.

4.

Position the appliance in its approximate working position.

5.

All air for burner combustion is supplied from underneath the unit. The legs must always be fitted

and no obstructions placed on the underside or around the base of the unit, as obstructions will

cause incorrect operation and / or failure of the appliance.

6. Components

having

adjustments

protected (e.g. paint sealed) by manufacturer are only allowed to

be adjusted by an authorised service agent. They are not to be adjusted by the installation person.

NOTE: Do not obstruct or block the appliances flue. Never directly connect a ventilation system to

the appliance flue outlet.

Installation

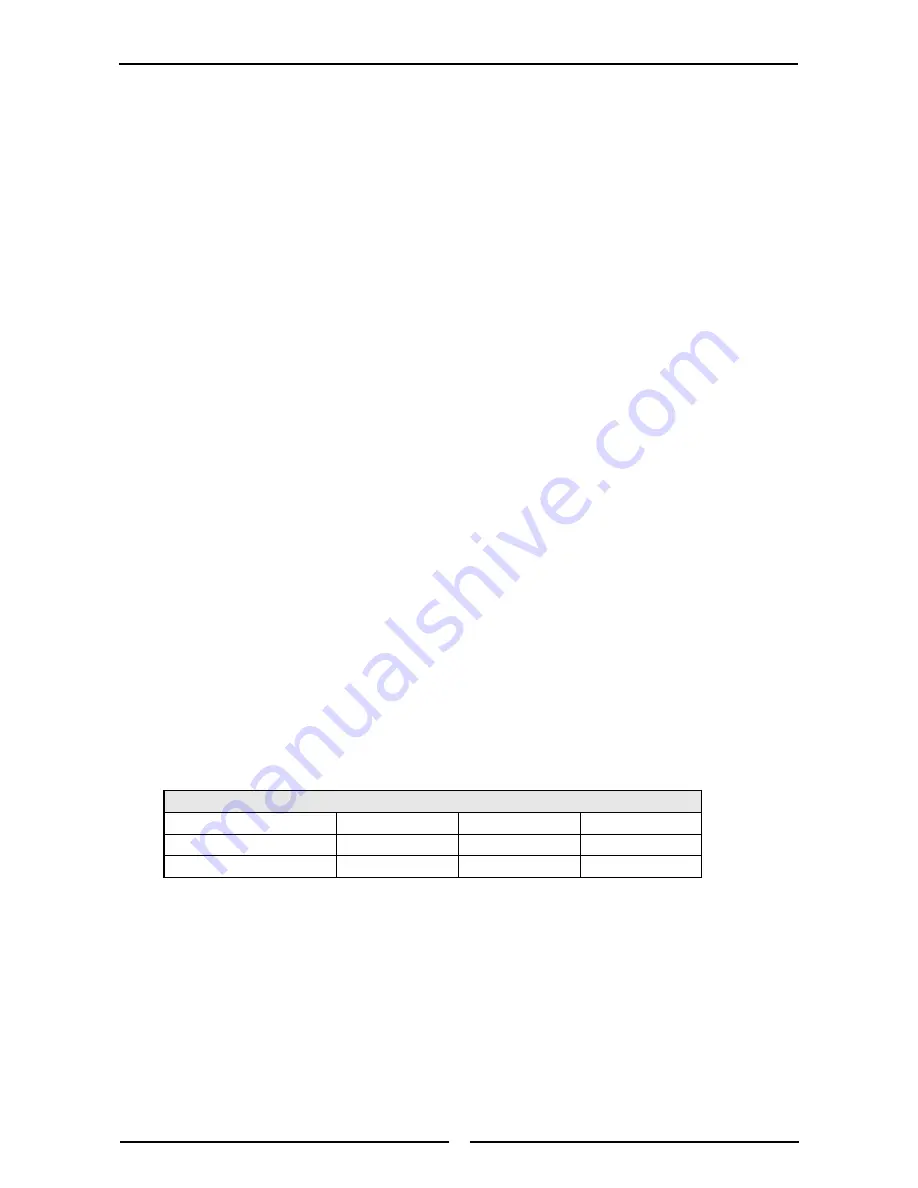

Combustion Air Requirements:

GP514 GP516 GP518

Natural Gas (G20)

14

m

3

/hr 21

m

3

/hr 28

m

3

/hr

LPG / Propane (G31)

15

m

3

/hr 22

m

3

/hr 29

m

3

/hr