13

Part 6 Gas Conversion

Gas Conversion Procedure

NOTE:

These conversions should only be carried out

by qualified service persons. All connections

must be checked for leaks before re-

commissioning the appliance.

For all relevant information and specifications

refer to the table at the end of this section.

Flexible Hose Connection;

If a Gas Hose assembly is used to connect this

appliance, the hose and all fittings must have

a minimum

¾

” (Natural Gas) or ½” (LPG)

inside bore diameter to ensure gas flow rate

capacity required by this appliance is

achieved.

This must be verified by operating pressure

testing at maximum gas supply demand

condition.

The Gas Hose assembly should also be

classified for use in the commercial kitchen

conditions, the appliance will be used in.

Recommended Gas Hose Assembly Specification:

- AS/NZS 1869 Class B or D compliant or

equivalent, that meets the following

requirements:-

1. Ensure that the gas supply

has been turned 'Off'.

2. Open the front door of the

fryer to access the main

burner and pilot burner in-

jectors.

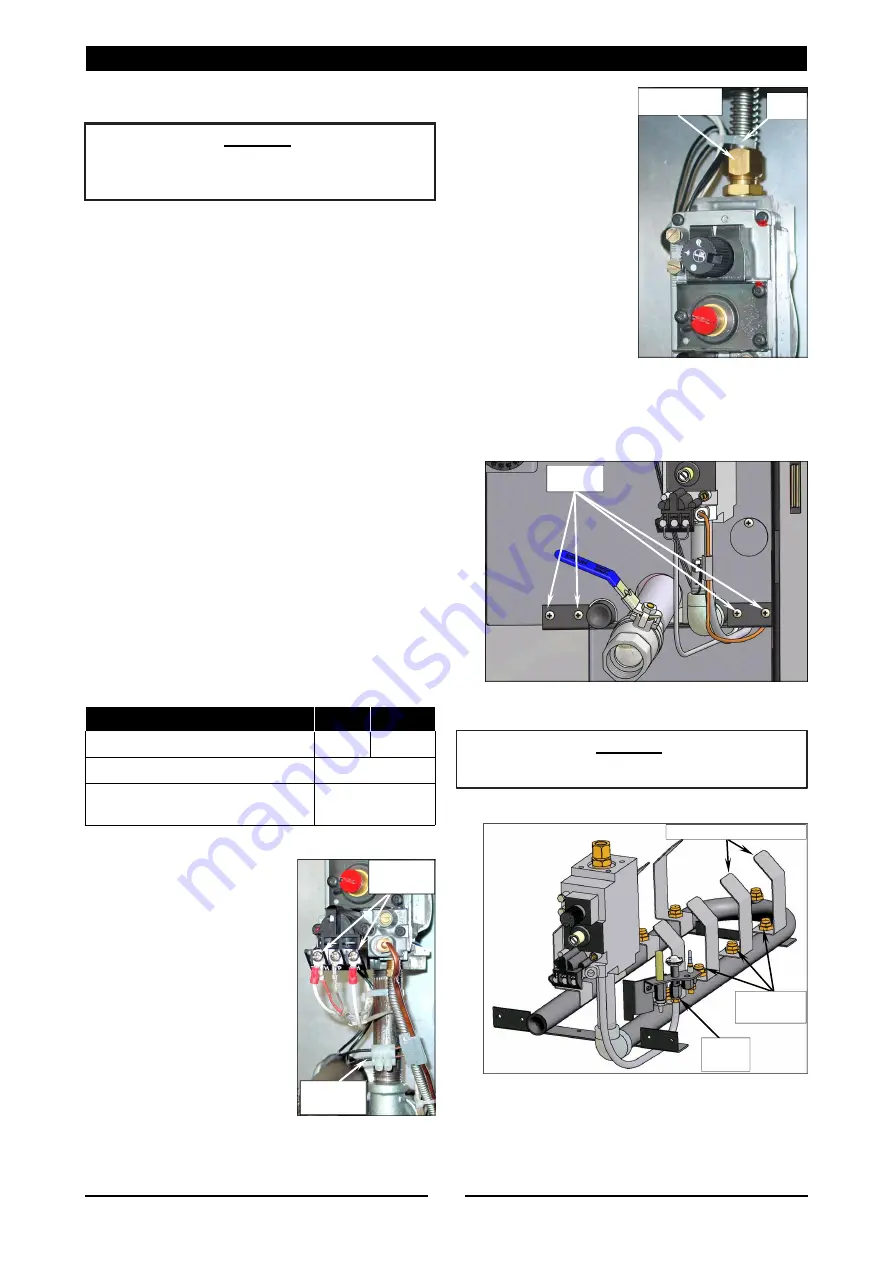

3. Disconnect 2 wires from the

Thermostat to the Gas

Control Valve.

4. Disconnect 2 wires from the

Overtemp at the electrical

connector.

5. Cut and remove any

cable ties as required

6. Disconnect the flexi

tube gas connection

at the top of the Gas

Control Valve.

7. Undo and remove the 4 screws securing the

front of the burner to the burner box.

8. Pull the burner towards the front of the fryer and

downwards to remove.

9. Remove the Burner Assembly to a workbench.

C

AUTION

:

Ensure that the Unit is isolated from the gas

supply before commencing servicing

Class

B

D

Max Working Pressure at 23 ± 2

ºC

7.0 kPa 2.6 MPa

Working Temperature Range

- 20

ºC to + 125ºC

Resistance to Oil

Oil resistant lining

and cover.

Overtemp

Wires

Thermostat

Wires

Disconnect Gas

Connection

Cut Tie

Wraps

Remove 4

Screws

Main Burner

Injectors (9)

Pilot

Injector

C

AUTION

:

Do not bend the Flame Deflector Plates.

Flame Deflector Plates

Summary of Contents for Evolution GT18 Series

Page 19: ......