6

Service Procedures

28

Blue Seal Evolution Series GT45 / GT46 / GT60

©

Moffat Ltd, January 2007

Revision 1/

1) Open door, and using screwdriver turn the

pilot adjustment screw.

Turning the screw anticlockwise increases the

pilot flow.

Turning the screw clockwise decreases the

pilot flow.

1) Remove thermostat control

knob (two

screws).

2) Fill fryer with oil. Light pilot burners and turn

on burners. With temperature probe in oil,

run burners until oil temperature reaches over

150°C. If it is a replacement thermostat

rotate the shaft a maximum of one full turn

anticlockwise and allow fryer to heat the oil.

When the burner has cycled off, turn shaft

again (max 1 full turn) until 150-200°C range

is reached.

3) Turn thermostat shaft until cycling on/off

point reached. Check oil temperature and

find point at which rotating shaft back and

forth slightly will cause burners to cycle on/

off.

4) Recheck oil temperature (should be between

150°C and 190°C) and refit control knob with

pointer at temperature setting on control

panel that reflects actual oil temperature.

Allow fryer to cycle and make any fine adjust-

ments of knob position if required.

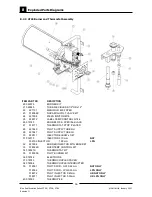

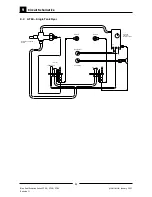

Figure 6.3.1

6.3.1 Pilot

adjustment

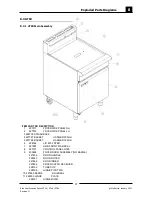

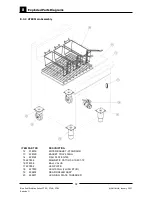

6.3.2 Thermostat

calibration

6.3 Adjustment / Calibration

Pilot

adjustment

screw

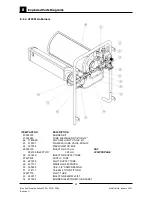

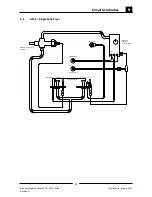

6.3.3 Operating

pressure

1) Unscrew operating pressure test point on the

gas control valve.

2) Fit manometer (pressure meter) to test point.

3) Light main burners.

4) Remove regulator cap.

5) Adjust operating pressure by turning regulator

screw until correct operating pressure is

achieved.

NAT gas: 1.0 kPa

LPG : 2.75 kPa

Figure 6.3.3