Always keep this instruction manual together with the tool and ensure that

they are handed over together to any other operator.

General information

Explanation of Terminology

WARNING

The word WARNING is used to

emphasize a

potentially

dangerous situation which could

lead to severe personal injury or

death.

CAUTION

The word CAUTION is used to

emphasize a

potentially dangerous

situation which could lead to minor

personal injury or damage to the

equipment or other property.

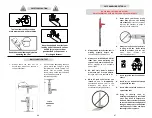

Graphic Symbols

GENERAL INFORMATION

DANGER! TO AVOID SERIOUS INJURY OR DEATH:

NEVER PLACE YOUR HAND AT THE END OF THE NOSE PIECE OF THE BP-27C TOOL.

OPERATORS AND BYSTANDERS AROUND THE TOOL BEING USED MUST USE EYE AND

EAR PROTECTION. ALWAYS ASSUME THAT THE TOOL IS LOADED WITH A LOAD.

NEVER PLACE YOUR FINGERS ON THE NOSE PIECE OF THE LOADED OR UNLOADED

TOOL UNTIL THE TOOL NOSE PIECE IS AGAINST THE WORK BASE AND YOU ARE READY

TO DO A FASTENING. IF THE TOOL ACCIDENTALLY SHOOTS HIS/HER HAND OR ANY

PART OF THE BODY, THE PISTON CAN ENTER THE BODY AND CAUSE SERIOUS INJURY

OR DEATH. IT IS VERY IMPORTANT THAT THE OPERATOR OF THIS BP-27C TOOL READS

AND UNDERSTANDS THE ENTIRE MANUAL AND COMPLETES THE OPERATORS EXAM

WITH A 100% GRADE. THE WARRANTY DOES NOT APPLY UNTIL BLUEPOINT

FASTENERS RECEIVES A COPY OF OPERATORS EXAM AND A COPY OF YOUR RECEIPT

WHEN THE TOOL WAS PURCHASED.

General Warning

Read Instructions Before

Use

Use Safety Helmet

Use Eye Protection

Use Ear Protection

WARNING! Hot Surface

03

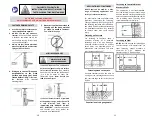

PRIOR TO OPERATING THE BP-27C TOOL, PLEASE STUDY THIS MANUAL CAREFULLY

AND DEVELOP A THOROUGH UNDERSTANDING OF THE CONTENTS. PROPER

TRAINING ACCORDING TO THE CURRENT ANSI STANDARD A 10.3, SAFETY

REQUIREMENTS FOR POWDER ACTUATED FASTENING SYSTEMS MUST BE

COMPLETED AND A BLUEPOINT FASTENERS QUALIFIED OPERATOR CARD MUST BE

OBTAINED PRIOR TO OPERATION OF THE TOOL. STATE, LOCAL, OR OTHER

REGULATIONS SHOULD ALSO BE FOLLOWED. LAWS, REGUATIONS, AND STANDARDS

REGARDING THE USE OF POWDER ACTUATED TOOLS MAY PERIODICALLY BE REVISED

WITHOUT NOTICE. ANY SUCH REVISIONS MAY CHANGE THE SAFETY AND OPERATING

PROCEDURES DESCRIBED IN THIS MANUAL. BLUEPOINT FASTENERS IS NOT

RESPONSIBLE FOR ANY SUCH REVISIONS WHICH OCCUR AFTER PUBLICATION OF THIS

MANUAL. IT IS THE RESPONSIBILITY OF THE USER TO MAINTAIN ALL KNOWLEDGE OF

THE LAWS, REGULATIONS, AND STANDARDS THAT APPLY TO POWDER ACTUATED

TOOLS.

WARNING!

BP-27C TOOL IS TO BE USED ONLY BY LICENSED OPERATORS. YOU MUST HAVE

A LICENSE BEFORE OPERATING IT. YOU MAY COMPLETE THE ENCLOSED EXAM

SUCCESSFULLY AND RETURN IT TO GET A TOOL

OPERATOR’S

CARD THAT WILL

BE ISSUED TO YOU, AND ALSO ACTIVATE YOUR WARRANTY.

OPERATOR’S

LICENSE CAN ALSO BE OBTAINED DIRECTLY AT: www.bpfasteners.com

WARRANTY

Bluepoint warranty assures that the

supplied

tool is free of defects in workmanship

or material. Validity of this warranty is applied as long as the tool is handled and

operated correctly, serviced and cleaned properly in accordance with the Bluepoint

Instruction Manual and only if original Bluepoint components, consumables and

spare parts or other equivalent quality products are used. Parts requiring

replacement or repairs as a result of normal wear and tear are not covered under this

warranty.

All warranties or products described herein, expressed or implied, including the

warranties of merchantability or fitness for a particular purpose, are specifically

excluded, with the following exceptions: Bluepoint Fasteners will repair or replace, at

its option, any tool, part or element holding that, within 90 days after the sale, only if

Bluepoint is found to be responsible for a defective part in material or workmanship,

excluding normal wear.

All additional claims are excluded, specifically, Bluepoint is not obligated for direct,

indirect, incidental or consequential damages, losses or expenses in connection with,

or by reason of, the use of, or inability to use the tool for any purpose.

THIS IS THE ONLY WARRANTY AND REMEDY BLUEPOINT HAS AVAILABLE AND

IS IN NO EVENT LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, OR ANY OTHER DAMAGES.

02

Summary of Contents for BP-27C

Page 12: ...23 NOTES 22 NOTES ...