•

Ensure

that

the

correct

combination

of

piston,

fastener guide, and fasteners

are used.

•

Check the piston, nose piece

and the strip load and replace

the

worn-out

parts

if

necessary.

•

Clean all the parts of the tool.

•

If the problem persists, DO

NOT use the tool . Have the

tool checked / repaired by a

Bluepoint professional.

SAFETY PRECAUTION

•

Never try to pry a cartridge from the

magazine strip or the tool.

•

Do not straighten your arms while

firing the tool. Keep them flexed.

•

Never

leave

the

loaded

tool

unattended.

•

Ensure that the tool is not loaded

before

servicing,

cleaning

or

replacing parts and before storing it.

•

Always store cartridges and unused

tools unloaded, in a dry location,

and in a high or locked place, out of

children’s

reach.

6.

Temperature

•

Do not dismantle the tool when it is

hot.

•

Never exceed the recommended

maximum fastener driving rate. (700

fastenings / hour).

•

Stop if the plastic cartridge strip

melts. Allow the tool to cool down.

7.

Requirements to be met by users

(Pre-requisites for users)

•

Only

authorized,

trained

professionals

should

operate,

service, and repair the tool. The

professional must be informed of

any special hazards that may be

encountered.

•

Operate the tool only if your full

attention is on the job.

•

Do not use the tool if you feel

unwell.

8.

Personal

Protective

Equipment

(PPE)

•

The

operator

and

all

other

bystanders must always wear eye

and ear protection and a hard hat.

Prior to use

9.

Read

the

Instruction

Manual

carefully.

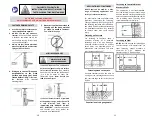

10. Inspection of tool

•

Ensure that the tool is not loaded.

•

Routinely check the tool for damage

and ensure that all controls operate

properly.

•

Check the buffer and piston for wear

(see table on last page of these

instructions).

11. Selection of the correct

nose piece

/ piston / fastener combination

•

Using the wrong combination may

result in damage to the tool and / or

affect fastening quality.

05

1.

General Safety Instructions

The following points must be

strictly observed at all times, in

addition to the specific safety

precautions listed in the individual

sections.

2.

Use as recommended

The tool is designed for use only by

professionals in the construction

industry for fastening applications

where

fasteners

or

composite

fasteners are driven into steel,

concrete.

3.

Inappropriate use

•

Modification or manipulation of the

tool is not permitted.

•

Unless the tool is approved for such

use, it should not be used in a

flammable

or

an

explosive

environment.

•

Use only BLUEPOINT fasteners,

cartridges, accessories or spare

parts of equivalent quality to avoid

risk of injury.

•

Strictly follow the instructions for

operation, care and maintenance

given in the Instruction Manual.

•

The tool should never be pointed at

self or any bystander.

•

The muzzle of the tool should never

be pressed against a hand or any

body part.

•

The nails are NOT to be driven into

materials such as marble, natural

rock, glass, copper, brass, bonze,

plastic, insulation materials, hollow

brick, glazed tile, thin sheet metal

(<4 mm), grey cast iron, spheroidal

cast iron or gas concrete.

•

The tool and its accessories may be

hazardous if used improperly by an

unauthorized person.

4.

Workplace safety

•

Avoid unergonomic body postures.

•

Hazardous

objects

should

be

removed from the work area.

•

The tool is only for hand-held use.

•

Other

bystanders,

particularly

children, should not be allowed in

the work area.

•

Make sure nobody is behind or

below the point where the fastener

is to be driven.

•

The tool grip should always be kept

free of oil or grease.

5.

Basic safety precautions

•

Operate the tool only in good

condition and only as directed.

•

Use the spall guard

/ stabilizer

when required.

•

If the cartridge fails to ignite or

misfires, please do the following:

•

Hold the tool pressed against

the working surface for 30

seconds.

•

If the cartridge still fails to fire,

withdraw the tool from the

working surface making sure it

is

not

pointed

towards

anybody or yourself.

•

Manually advance by one

cartridge

and

use

the

remaining cartridges on the

strip.

•

If

2-3

cartridges

misfire

in

succession (without making any

audible firing noise and if the

fastener is driven with significantly

less force), do the following:

•

Immediately STOP using the

tool.

•

Dismantle the tool.

SAFETY PRECAUTION

04

Summary of Contents for BP-27C

Page 12: ...23 NOTES 22 NOTES ...