- 38 -

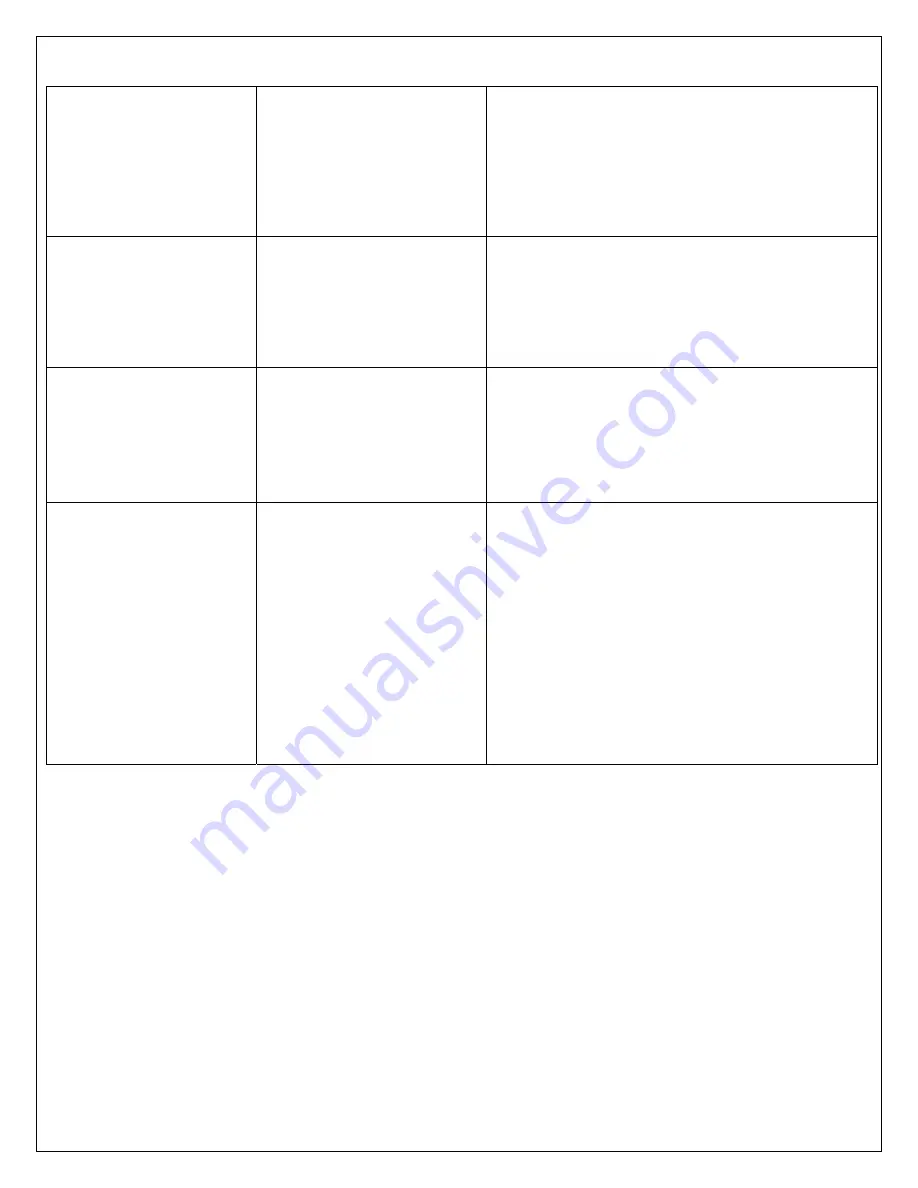

ports

c) An orifice hood out of line

on burner throat will

reduce primary air injection

d) Faulty drilling or dirty

orifice

c) Align orifice hood with burner venturi.

d) Clean orifice or replace faulty drilled orifice.

Lifting flames – flames rise

from the ports to burn some

distance above the port, also

known as noisy flame.

Lifting burner flames result

when the flow velocity or air

and gas mixture from a port

exceeds the flame velocity.

(Flame velocity is the speed at

which a flame moves through a

fuel/air mixture)

Reduce primary air or adjust (making port smaller) air

shutter on burner.

Fluctuating

flame

Normally caused by non-

uniform gas pressure.

1) Check gas pressure

•

Supply

•

Regulator

2) Check orifice for blockage

•

Metal shavings

•

Dirt/dust

•

Excess grease from burner valve

Floating flame – lazy

appearance and no well-

defined inner cone. It will

appear to be “reaching” for

air. Normally, a strong

aldehyde odor is present.

Aldehyde is a class of

compounds which have a

pungent, distinct odor.

a) Lack of secondary air.

Combustion products re-

circulated in the burner box

will contaminate the air

supply.

b) The appliance may be over-

rated. If so, the flue outlet

area may be too small for

the gas rate.

a)

•

Open secondary air inlets

b)

•

Decrease gas flow rate

•

Check and clear and blockage found in the

flueway

•

Check for blockage of burners and clean if

necessary

•

Adjust primary air to get rid of any yellow

tipping which may have produced soot that has

blocked the flueway