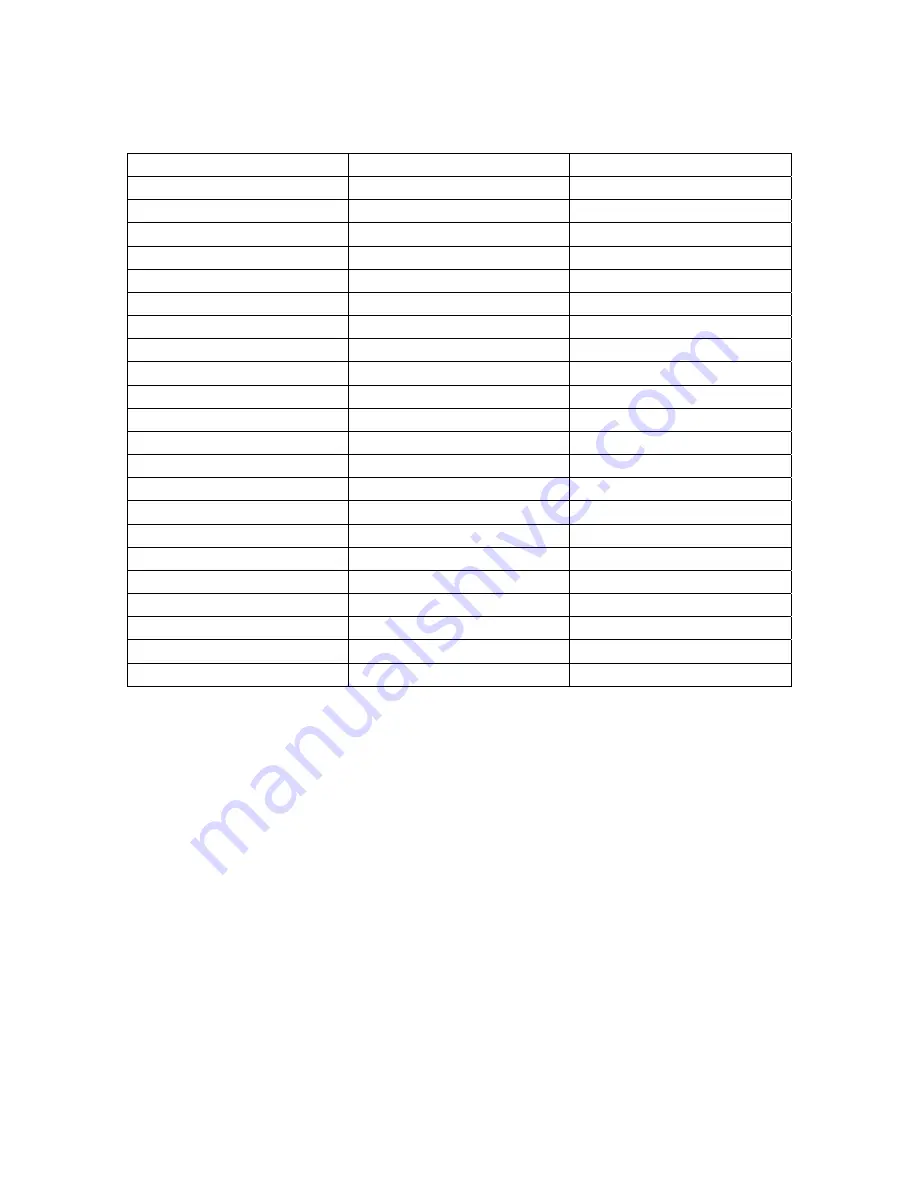

Gas Connection Size

Model

Weishaupt Burner

Riello Burner

12

½" BSP

½" BSP

15

½" BSP

½" BSP

18

½" BSP

½" BSP

23

½" BSP

½" BSP

30

½" BSP

½" BSP

44

¾" BSP

½" BSP

59

¾" BSP

¾" BSP

88

¾" BSP

¾" BSP

117

1" BSP

¾" BSP

147

1" BSP

¾" BSP

176

1½" BSP

1" BSP

205

1½" BSP

1" BSP

235

1½" BSP

1¼" BSP

264

1½" BSP

1¼" BSP

293

1½" BSP

1¼" BSP

352

2" BSP

2" BSP

440

2" BSP

2" BSP

513

2" BSP

2" BSP

586

2" BSP

2" BSP

733

2" BSP

2" BSP

880

2" BSP

2" BSP

952

2" BSP

2" BSP

Further Information regarding pipe work to the burner can be found in the

burner manual attached to this document.

18