SFU-0302 SSE

M a n u a l

– 7–

BMR GmbH

2014-03-17

E

!

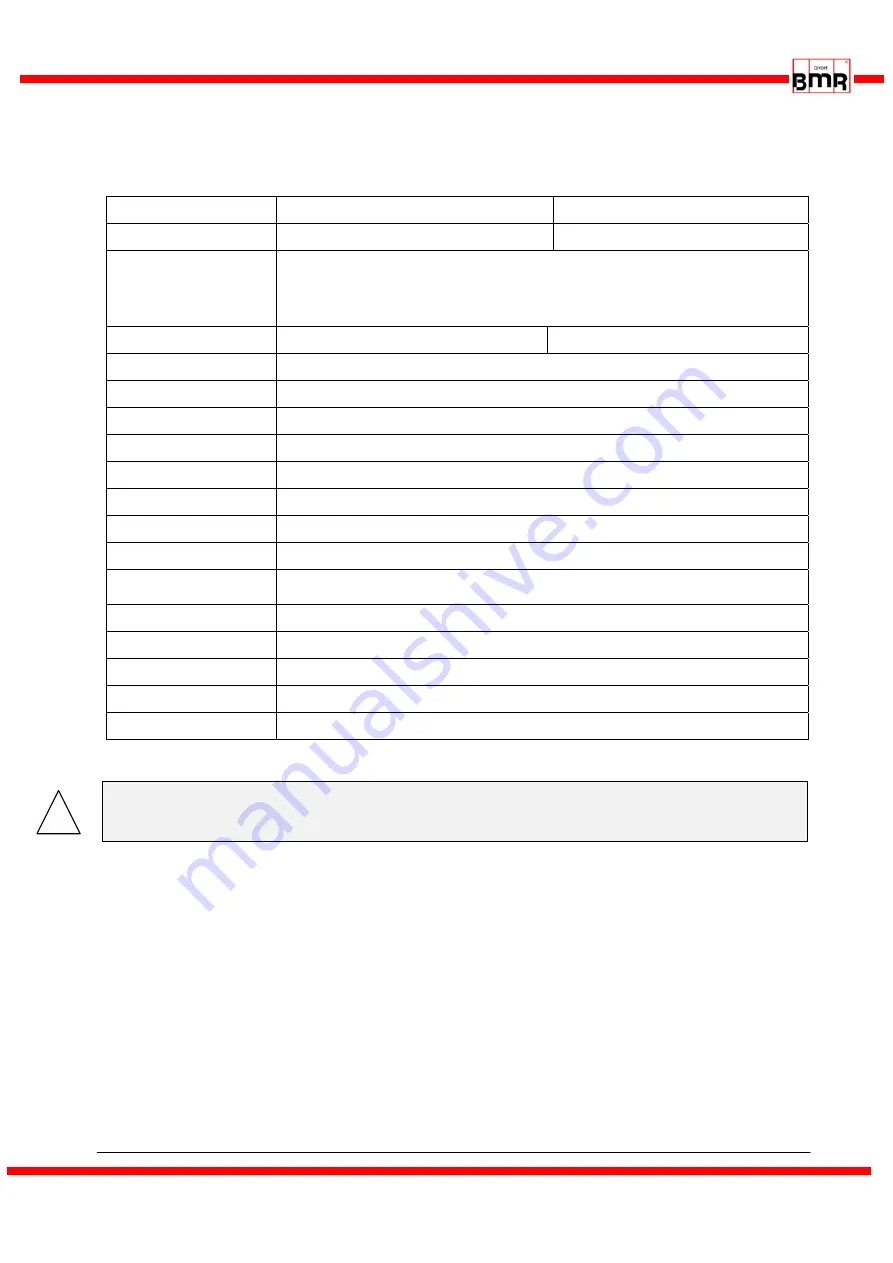

4. Technical Data

Supply connection

115V, 60Hz, 1PH

230V, 50Hz, 1PH

Output power

Max 2 kVA

Max 3,6 kVA

Motor connection

7-pole: U, V, W, PE, 2*PTC, SGND

Type: Amphenol C16-1 (fem. 6+PE) / Binder 693 (fem. 6+PE)

8-pole: U, V, W, 2*PE, PTC, FP, SGND screw terminals 4mm

2

Output voltage

3* 115V

3* 230V

Output current

Electronically limited

Over-current max.

10s

Output frequency

AC: 3kHz / 180.000 rpm DC: 60.000 rpm

Spindle characteristics

max 16, stored internally, freely definable

Spindle sensor inputs

PTC, magneto-resistor, logic (D-Sub 15-pin fem. )

Control inputs

2 analogue: 0-10V, galvanically separated : (D-Sub 25-pin fem. )

Control inputs

6 digital: 0-24V, galvanically separated: (D-Sub 25-pin fem. )

Control outputs

2 analogue: 0-10V, galvanically separated (D-Sub 25-pin fem. )

Control outputs

6 digital: relay outputs, (D-Sub 25-pin fem. )

24VDC/1000mA, 125VAC/500mA

Interface

RS232 galvanically separated, 9600Bd (D-Sub 9-pin male )

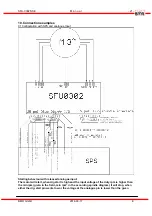

Housing dimensions

width 130mm, height: 320mm (with mounting straps: 380mm), depth: 262mm

Weight 7

kg

Protection IP20

Operating conditions

max. ambient temperature 40°C, no humidity

CAUTION: To avoid severe motor / spindle damage, select correct

motor / spindle characteristic !

Summary of Contents for SFU-0302-SSE

Page 1: ...Frequency Converter SFU 0302 SSE ...

Page 5: ...SFU 0302 SSE M a n u a l 5 BMR GmbH 2014 03 17 E 3 Block Diagram ...

Page 6: ...SFU 0302 SSE M a n u a l 6 BMR GmbH 2014 03 17 E ...

Page 28: ...SFU 0302 SSE M a n u a l 28 BMR GmbH 2014 03 17 E 13 Mechanics Views Dimensions ...

Page 29: ...SFU 0302 SSE M a n u a l 29 BMR GmbH 2014 03 17 E this page is left intentionally left blank ...