7

Work mode

7.5

Prepare work operation

86

7.5

Prepare work operation

1.

Make sure that the delivery hoses and couplings are in perfect condition

and correctly connected (see Section 7.4).

WARNING

Risk of injury due to hazardous materials.

Spillage of oil in the motor compartment can cause fires and toxic fumes.

−

Wipe off spilled oil (hydraulic oil, compressor oil, oil for diesel motors)

directly with an absorbent cloth.

−

Use a funnel when filling.

−

Only carry out work after the machine has cooled down sufficiently.

2.

Check the oil level on the diesel motor. Proceed as follows:

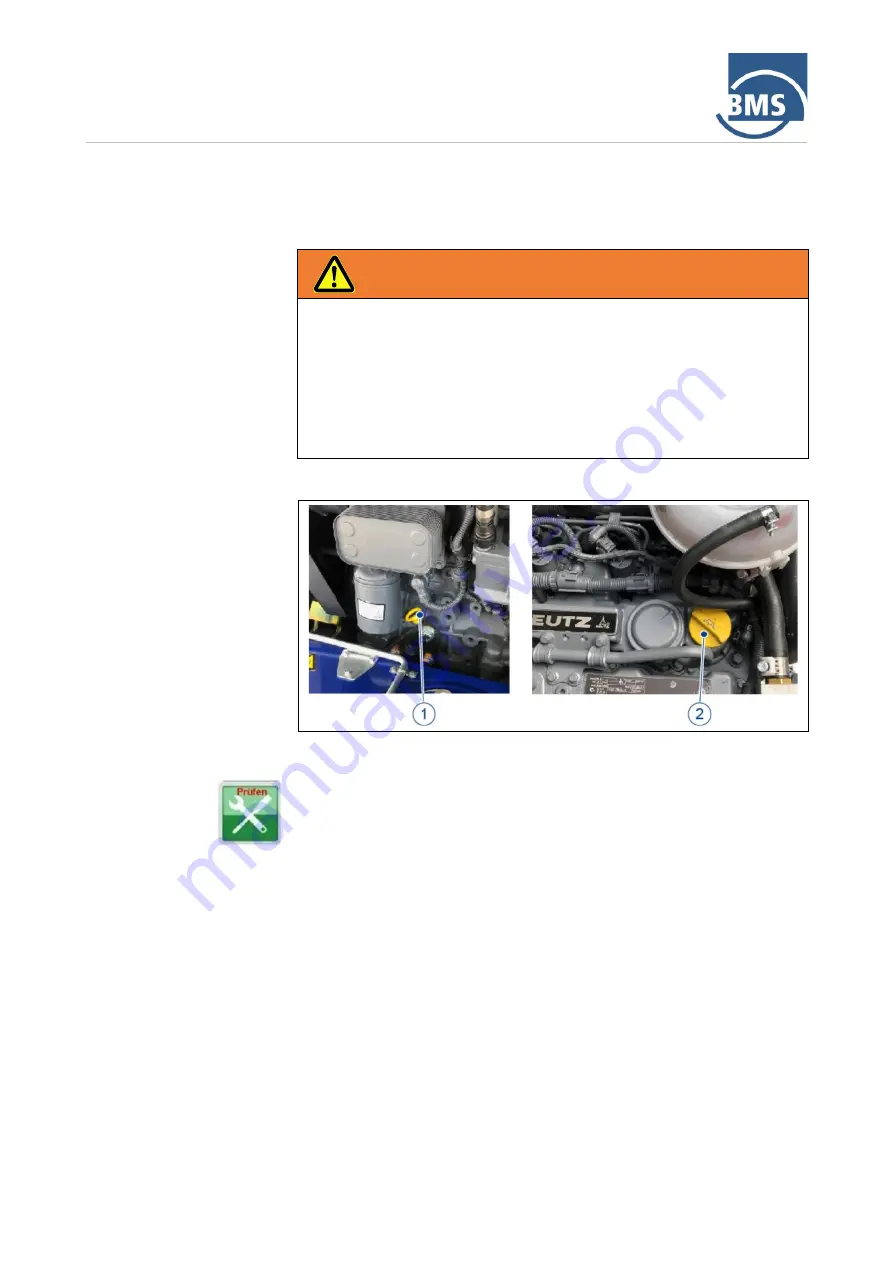

Figure 42: Check oil level

−

Pull out the oil dipstick (1) when the motor is warm and wipe it

with a lint-free cloth or absorbent paper.

−

Then insert the oil dipstick (1) and pull it out again after 10 s.

−

Carry out a visual inspection of the oil dipstick (1). The oil must be

between the MIN and MAX marks. If the oil level is near MIN or

below MIN, a corresponding amount of oil must be topped up via

the oil filler neck (2).

➢

The oil must not exceed the MAX mark.

Summary of Contents for alpha CR

Page 6: ...Contents ...

Page 180: ...14 Appendix 14 1 Declaration of conformity 180 14 1 Declaration of conformity ...

Page 181: ...Appendix 14 Drawings 14 2 181 14 2 Drawings 14 2 1 BMS alpha CR standard ...

Page 182: ...14 Appendix 14 2 Drawings 182 14 2 2 BMS alpha CR B feeder ...

Page 183: ...Appendix 14 Drawings 14 2 183 14 2 3 BMS alpha CR B S feeder scraper ...

Page 185: ...Appendix 14 Circuit diagrams 14 3 185 ...

Page 186: ...14 Appendix 14 3 Circuit diagrams 186 ...