info@bmspower.com

www.bmspower.com

© Es gelten ausschliesslich unsere allgemeinen Geschäftsbedingungen

Seite 25 von 32

BMS

energy

®

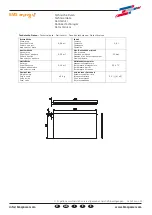

SS-45

Betriebsempfehlungen

Operating tips

Consigli per la messa in funzione

Recommandations d’emploi

Recomendaciones para el funcionamiento

28

Flushing and filling

For safety reasons, you should only fill the collectors when there is no direct irradiation from the sun (or cover the

collectors). Especially in regions exposed to frost, for flat plate collectors you should use a mixture of (FS)

antifreeze with water (40% antifreeze). The solar thermal system should be filled and commissioned within one

week of installation, because heat build-up in the collector (array) can damage the flat gaskets in empty systems.

If this is not possible, the flat gaskets should be replaced before commissioning to prevent leakage.

Attention:

Antifreeze that is not pre-mixed must be mixed with water prior to filling!

Recommended antifreeze for flat plate collectors: TYFOCOR-L

40% proportion of antifreeze (60%/water) - freezing point: -22° C/solidification point: -26° C

50% proportion of antifreeze (50%/water) - freezing point: -32° C/solidification point: -44° C

It may not be possible to completely empty collectors once they have been filled. For this reason, collectors

exposed to frost should only be filled with a water/antifreeze mixture, also for pressure and function tests.

Alternatively, the pressure test can also be carried out using compressed air and leak detection spray.

Installing the temperature sensor

The temperature sensor should be installed in the sensor sleeve nearest to the collector array flow. To ensure

optimal contact between the sensor and the surrounding environment, the gap between the sensor sleeve and

the sensor element should be filled with a suitable conducting compound. All materials used for installing

temperature sensors (sensor element, conducting compound, cables, sealing and insulating materials) must be

suitably temperature resistant (up to 250° C).

Operating pressure

The maximum operating pressure is 10 bar.

Bleeding

The system must be bled:

- when commissioning the system (after filling the collectors)

- 4 weeks after commissioning

- when necessary, e.g. if there are malfunctions

Warning:

Risk of scalding due to steam and hot heat transfer fluid!

Only operate the bleeding valve if the temperature of the heat transfer fluid is

< 60° C

.

When bleeding the system, the collectors must not be hot! Cover the collectors and, if possible, bleed the system

in the morning.

Check heat transfer fluid

The heat transfer fluid must be checked every two years with regard to its antifreeze and pH value.

- Check antifreeze using antifreeze tester and replace or refill if necessary!

Target value is ca. - 25° C and - 30° C depending on climatic conditions.

- Check pH value with a pH indicator rod (target value approx. pH 7.5):

If the limit pH value is less than

≤

pH 7, replace the heat transfer fluid.

Maintenance of the collector

The collector or the collector array must be inspected visually, once a year, for any damage, leaks and

contamination.

Additional recommendations on operation and maintenance can be found in the supplier's general documentation

and instructions on commissioning and maintenance.

Betriebsempfehlungen

Operating tips

Consigli per la messa in funzione

Recommandations d'emploi

Recomendaciones para el funcionamiento

D

E

F

I

GB