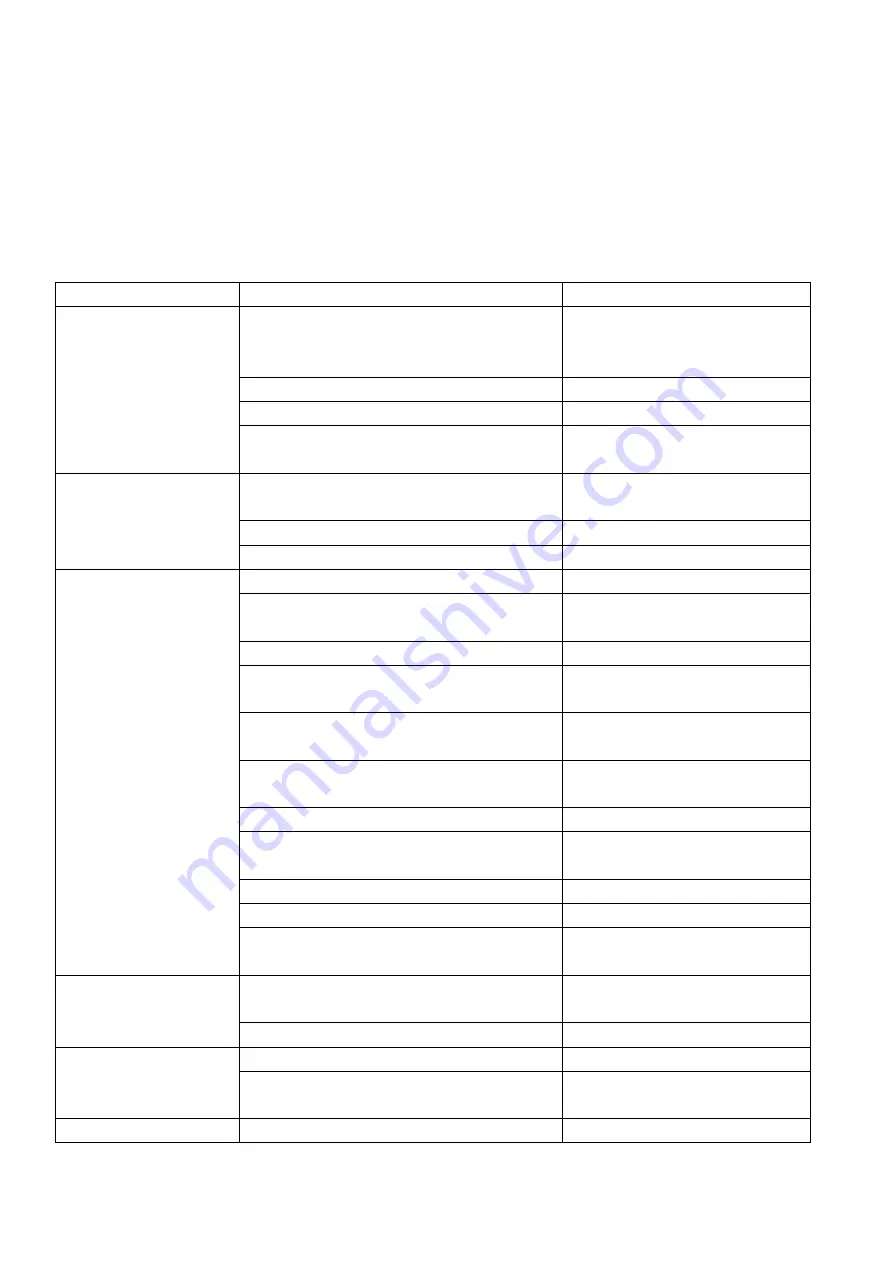

Troubleshooting Tables

If difficulties should be encountered in the course of operation, and no major instrument malfunctions can

initially be detected, please recheck the symptoms, referring to the tables provided below, before contacting

your service representative.

1. Optical

Symptoms Causes Countermeasures

Revolving nosepiece not in click-stop

position(objective not centered optical path)

Revolve to click-stop position

(swing the objective correctly into

the optical path)

Field diaphragm not centered

Centering

Field diaphragm closed too far

Open properly

Darkness at the

periphery, or uneven

viewfield brightness.

Dirt or dust on the lens (condenser,

objective, eyepiece, slide)

Cleaning

Dirt or dust on the lens (condenser,

objective, eyepiece, slide)

Cleaning

Dirt or dust on the slide.

Cleaning

Dirt or dust in the

viewfield

Condenser position too low

Correct positioning

No coverglass attached to the slide

Attach coverglass

Coverglass too thick or thin

Use coverglass of specified

thickness(0.17mm)

Slide upside-down.

Turn over the slide

Immersion oil on dry system objective

(especially 40X)

Cleaning

Dirt or dust on the lens (condenser,

objective, eyepiece, slide)

Cleaning

No immersion oil used on immersion system

objective

Use immersion oil

Air bubbles in immersion oil

Remove bubbles

Condenser aperture and field diaphragm

opened too far

Close properly

Dirt or dust on the entrance lens.

Cleaning

Condenser aperture closed too far

Open properly

Poor image quality

(low resolution or

contrast)

Condenser position too low

Raise to the position where the

diaphragm image is in focus

Revolving nosepiece not in click-stop

position

Revolve to click-stop position

Image dark on one side

Floating specimen

Fasten securely

Specimen rises from stage surface

Place it stable

Image shifts during

focus

Revolving nosepiece not in click-stop

position

Revolve to click-stop position

Image tinged yellow

Daylight filter not used

Use daylight filter

Summary of Contents for C2

Page 2: ...OVERVIEW ...