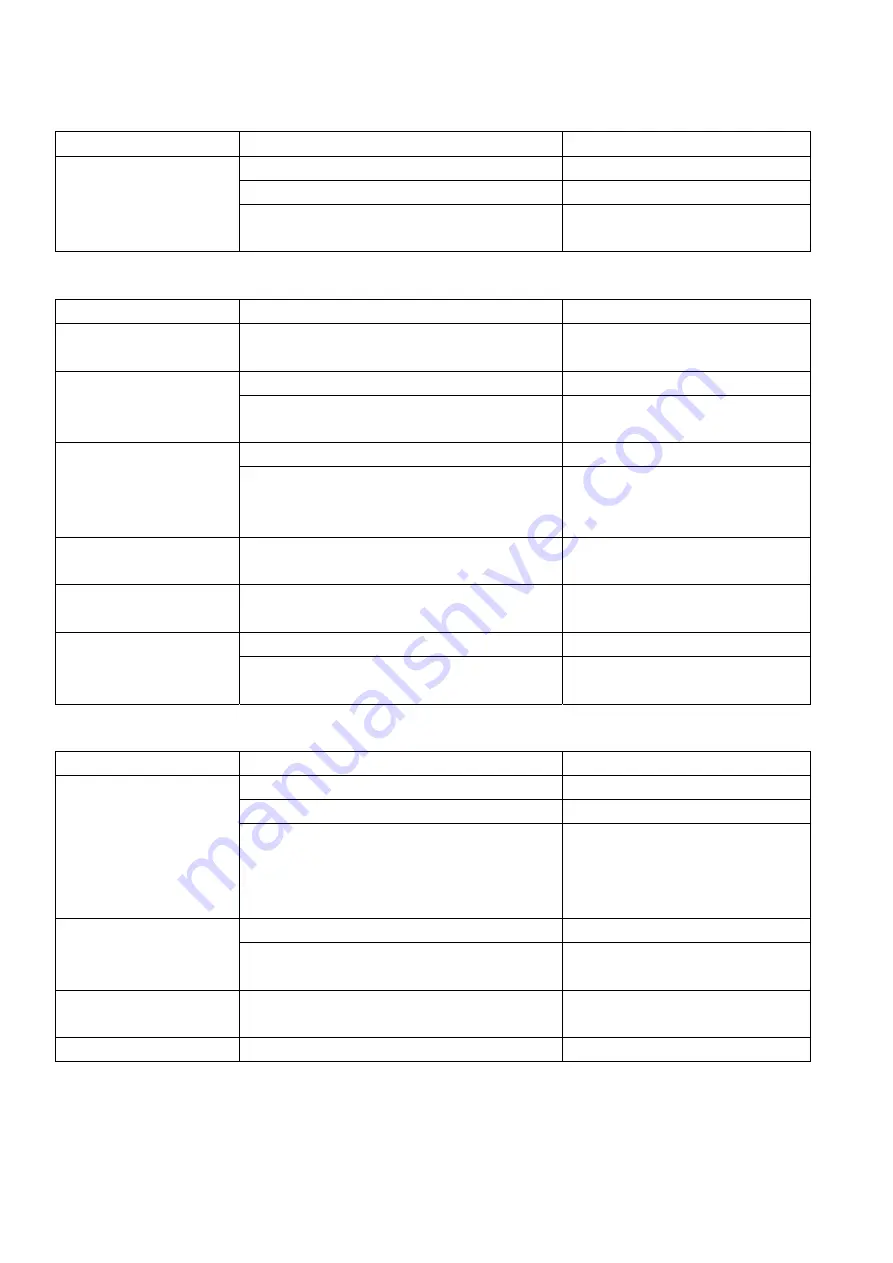

Symptoms Causes Countermeasures

Condenser aperture too small

Readjust aperture

Condenser position too low

Correct positioning

Insufficient illumination

brightness

Dirt or dust on the lens (condenser,

objective, eyepiece, slide)

Cleaning

2. Mechanical

Symptoms Causes Countermeasures

Specimen image

movement unsmooth

Mechanical stage not securely fastened

Tighten all fasteners

Slide upside-down

Turn slide over

Image not focusable

with high power

objectives

Coverglass too thick

Use coverglass of specified

thickness(0.17mm)

Slide upside-down

Turn slide over

High power objective

contacts slide when

changed-over from low

power

Coverglass too thick

Use coverglass of specified

thickness(0.17mm)

Specimen image

movement unsmooth

Mechanical stage not securely fastened

Tighten all fasteners

Binocular image not

integrated

Interpupillary distance not correctly adjusted

Adjustment

Incorrect diopter adjustment

Correct adjustment

Excessive eye fatigue

Inadequate brightness or illumination

Adjust brightness with control

dial

3. Electrical

Symptoms Causes Countermeasures

No electrical power

Check power cord connection

Lamp bulb not inserted

Insert correctly

Lamp does not light

when switched ON

Lamp failure

Replacement

If the same symptom occurs after

replacing the lamp, contact your

dealer

Unspecified lamp bulb used

Replace with specified lamp bulb

Insufficient illumination

brightness

Voltage too low

Increase brightness with control

dial

Unstable lamp

brightness

Lamp bulb about to fail

Replacement

Lamp bulb not correctly inserted into socket

Check for positive connection

Summary of Contents for C2

Page 2: ...OVERVIEW ...