After setting the 1st operation rollers rotate the head for a further 1 rotation. This is the

position where the bearings mounted on the Cam Follower Levers (2nd operation) are

at the topmost position.

At this point adjust the 2nd operation rollers by moving them inwards till the gap

between the lip of the seaming chuck and roller groove is 1mm.

Use a feeler gauge for making the adjustments.

Note:

The actual required roller pressure depends on the flange widths, sheet material

thickness, etc. and hence needs to be set differently for each type of can for which the

operator must use their best judgment. Refer to the attached Seam trouble shooting

guide for assistance.

2.

Roller Height Setting:

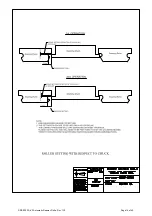

To adjust the roller height, the entire roller assembly must be raised or lowered. To do

so, loosen the bolt located on top of the roller pin (above the seaming lever). Rotate the

roller with a spanner to the desired height and then tighten the bolt. The correct height

is when the lip of the roller is just free of the lip of the chuck (Typically between 0.08

and 0.1mm). Tighten the bolt above the roller once set.

This setting can be done at the same time when adjusting the roller pressure.

Can Height Setting

The machine can accommodate various Can heights within permissible limits.

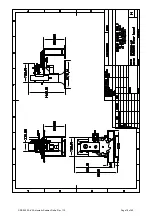

To change the height the entire Seaming head assembly has to be moved upwards or

lowered as required. This is done by loosening the bolts on the adjustment slides (SAV-

167) and turning the Height Adjustment Wheel (SAV-79) to raise / lower the head

assembly. Refer Figure 7.

When changing from a larger to smaller height Can, place the Can on the base plate

and lower the head till the chuck sits tightly on the Can.

When changing from a smaller to larger height Can, first raise the head and then lower

it onto the larger height Can.

The correct height setting can be noted from the position of the Pin in the main lifting

shaft (refer Figure 7). With a Can in place, lift the shaft using the Touchscreen. The

right height setting is when the Pin in the shaft is at the centre position.

Once the desired height level has been achieved, tighten all the bolts on the slide ways.

Do not operate the machine with the bolts in a loose position as this can cause the

slides to slip and may result in damage to the machine.

No adjustments to the Can movement arms are required for Can height changes. The

Seaming Chuck and Rollers also need not be adjusted.

SRS:200:FA-V3 Automatic Seamer. Delta. Rev 1.10

Page 8 of 60

Summary of Contents for SRS:200:FA-V3

Page 16: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 16 of 60 ...

Page 17: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 17 of 60 ...

Page 18: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 18 of 60 ...

Page 19: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 19 of 60 ...

Page 20: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 20 of 60 ...

Page 21: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 21 of 60 ...

Page 22: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 22 of 60 ...

Page 23: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 23 of 60 ...

Page 24: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 24 of 60 ...

Page 25: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 25 of 60 ...

Page 26: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 26 of 60 ...

Page 27: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 27 of 60 ...

Page 28: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 28 of 60 ...

Page 29: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 29 of 60 ...

Page 30: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 30 of 60 ...

Page 31: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 31 of 60 ...

Page 32: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 32 of 60 ...

Page 33: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 33 of 60 ...

Page 34: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 34 of 60 ...

Page 35: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 35 of 60 ...

Page 36: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 36 of 60 ...

Page 37: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 37 of 60 ...

Page 51: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 51 of 60 ...

Page 52: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 52 of 60 ...

Page 53: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 53 of 60 ...

Page 54: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 54 of 60 ...

Page 55: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 55 of 60 ...

Page 56: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 56 of 60 ...

Page 57: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 57 of 60 ...

Page 58: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 58 of 60 ...

Page 59: ...SRS 200 FA V3 Automatic Seamer Delta Rev 1 10 Page 59 of 60 ...