Page 18

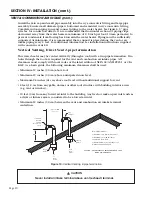

Install piping through the wall as shown in Figure 6. Adequate length of pipe must protrude

beyond the exterior wall for attachment of the termination fitting. The recommended

distance between the terminal fitting and the exterior wall is 1 in. (2.5 cm). Directions for

cementing joints (such as the terminal fittings to the straight pipe) can be found on page 24.

Two 45

°

elbows are provided with the water heater for termination fittings. If other fittings are

required (i.e. 90

°

elbows) they must be purchased separately. Install a screen inside the air

intake termination fitting to prevent items from entering the system. Complete the installa-

tion of the remainder of the vent and air intake system and attach to the water heater as

shown in Figure 7. It is recommended that horizontal sections of piping slope downward away

from the water heater a minimum of 1/8 inch per foot (10 mm per meter) to prevent

condensate from flowing back towards the water heater.

CAUTION

Annular spaces around vent pipe wall penetrations shall be permanently sealed using

approved materials to prevent entry of combustion products into the building.

䊱

!

SECTION IV: INSTALLATION (cont.)

VENT & COMBUSTION AIR INTAKE (cont.)

Vent Terminal

From

Water

Heater

Wall

Outside of

Building

Inside of

Building

Vent Pipe

12" (30 cm)

or greater

Ground Level

Wall Section View

Figure 6:

Horizontal Venting, 1-pipe termination

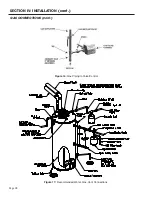

Before Elbow

4" MIN

Vertical Length

Vent (To Outside)

Air Intake

(From Inside)

3" Pipe

3" Pipe

Air Intake

(From Inside)

Vent (To Outside)

3" pipe systems

4" pipe systems

Exhaust

Adapter

Fitting w/ protective

screen

Fitting w/ protective

screen

Before Elbow

4" MIN

Vertical Length

3" Pipe

3" Pipe

4" x 3"

Reducing Coupling

4" Pipe

Exhaust

Adapter

Figure 7:

Horizontal Power Vent Connections to Water Heater