Page 47

SECTION VI: MAINTENANCE

FLUSH THE TANK

Elements in the water such as lime and iron may accumulate in the heater. Accumulation of

these elements can keep your water heater from operating at peak efficiency and may lead to

premature tank failure. It is recommended that the tank is drained and flushed thoroughly

twice a year to prevent buildup.

CHECK THE COMBUSTION SYSTEM

On an annual basis, verify that the combustion system is operating within acceptable

parameters. Gas pressures and combustion measurements can be used to verify proper

operation.

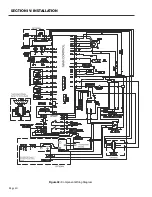

• Check the inlet gas pressure to the gas control (use factory installed inlet pressure tap port,

see Figure 37). The pressure should be greater than 4.0” W.C. (natural gas) and 8” W.C. (LP

gas) when the burner is operating at high fire. Gas pressure shall not exceed 14” W.C. when

the burner is off.

• Measure the products of combustion in the exhaust vent. At maximum input, the % O

2

in the exhaust gas should be in the range of 3.0 - 4.5%. CO should be less than 25 ppm.

• If adjusting the combustion is necessary it will require adjustments to the throttle and/or

offset settings. At high fire, the throttle controls the combustion. Use a small flat head screw

driver to turn the throttle screw CCW (more fuel), or CW (less fuel). At low fire, the offset

controls combustion. Use a 2.5mm Allen key. Turning the adjustment CW decreases the fuel

flow, CCW increases fuel flow. If measurements are not within range, contact Bock Technical

Support for adjustment instructions.

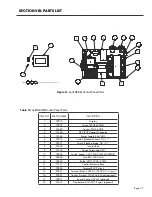

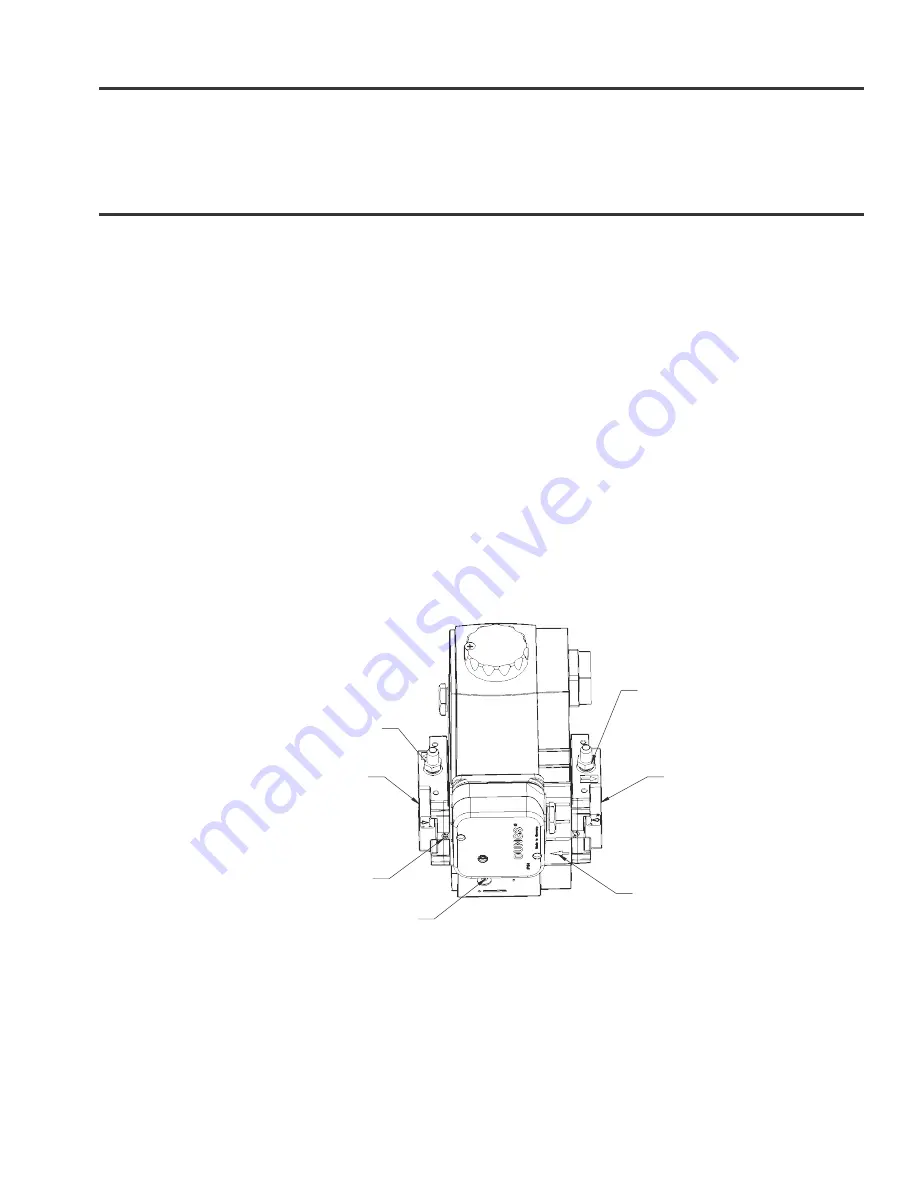

INLET PRESSURE TAP PORT

OUTLET (MANIFOLD)

PRESSURE TAP PORT

INLET SIDE

OUTLET SIDE

GAS FLOW DIRECTION

THROTTLE

OFFSET

Figure 37: Gas Control