Page 9

SECTION II: GENERAL INFORMATION

BURNER RELEASE (DRAFT SYSTEM INTERLOCK)

The Burner Release setting provides the option to connect the water heater to a mechanical

draft control. Mechanical draft controls shall only be utilized when vent lengths exceed the

limits specified in this manual. Consult Bock Water Heaters and the manufacturer of the

mechanical draft system for recommendations on pressure sensor location and setpoint in

the exhaust vent. Note: An Enervex EBC24 modulating fan control was referenced for feature

design.

To achieve a proper interlock between the water heater and the draft control, all wiring shall

be in accordance with both the draft control and water heater installation manuals. The

interlock strategy will utilize a dry set of contacts on the water heater.

Two pairs of wires are needed for the connections at the water heater and are located at the

850IF control on the control panel. The red (“R”) pair, labeled “Call for Heat Output”, provides

a normally open dry contact that closes when a call for heat (i.e., Demand) is initiated by

the water heater’s main operating control. The red pair will typically be used in series to

switch the hot side of a low voltage supply to an input on the draft control. The black/white

(“BK/W”) pair, labeled “Burner Release Input,” is controlled by a volt free contact on the draft

control and typically connected to an output on the draft control. This circuit is closed when

the draft control has satisfied its safeties and is allowing the water heater to proceed with an

ignition sequence. Refer to the wiring diagrams in this manual for wire pair locations and the

building draft control manual for detailed connection diagrams.

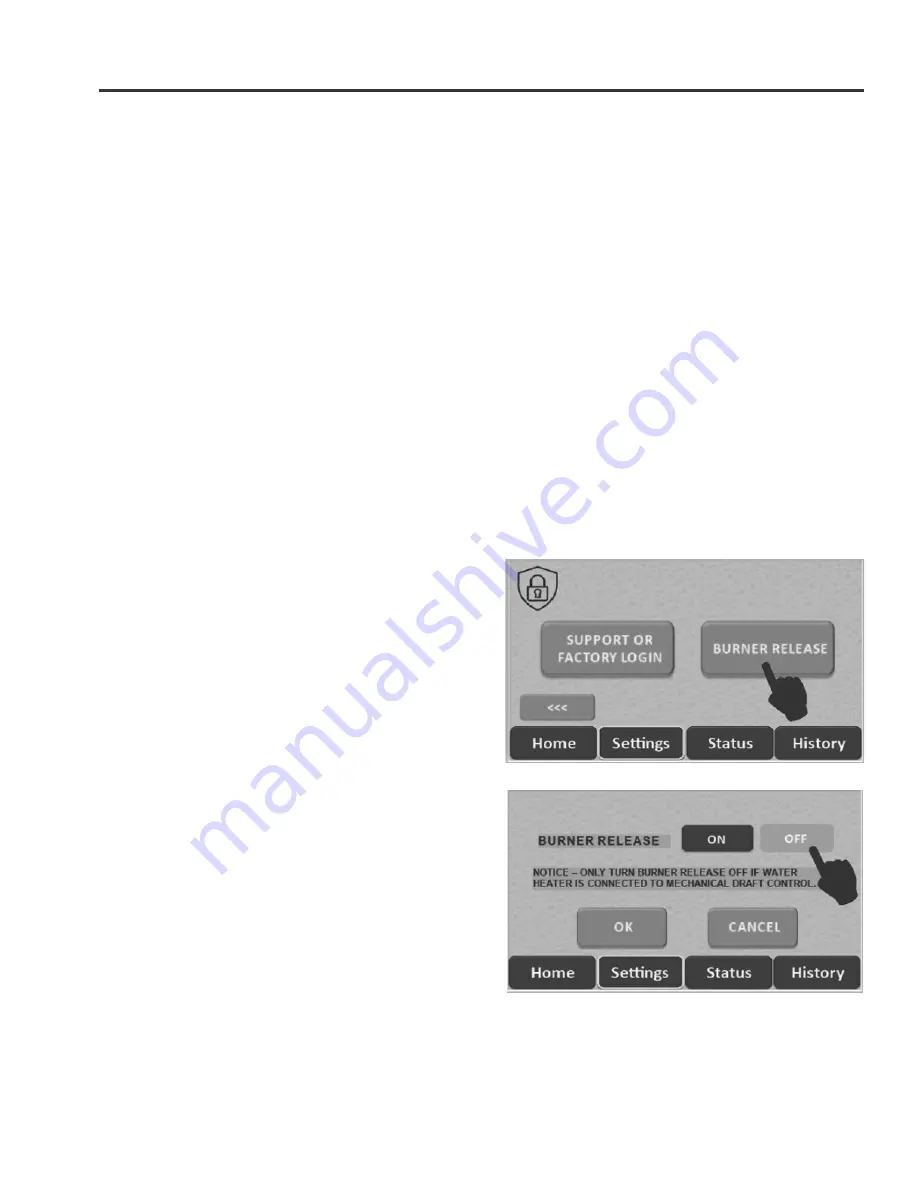

To adjust the Burner Release setting via the display, perform the following steps:

1) Navigate to the Settings tab. Select the

Advanced option, and then select Burner

Release.

2) The default setting for Burner Release is

ON. This setting automatically initiates the

burner lighting sequence during a call for

heat. To change the setting, press the Burner

Release button at the bottom of the screen.

3) A new window appears where the setting

may be changed. Select the new setting and

press OK. Verify that the setting is correct on

the Burner Release screen.

4) If Burner Release was changed to OFF,

the burner ignition sequence will only start

when the mechanical draft control releases

the burner for operation.