STEP #5 ENABLE THE INVERTER AND APPLY AC POWER

> After installation is complete,

and after the building power commissioning has been completed,

apply AC mains power and then turn on SW-1 on the ELI-S-250 Circuit board.

NOTE:

The ELI-S-250 & ELI-S-185 features a “power commission lockout” that prevents the inverter from operating in the

Emergency Mode unless charging power (UNSW HOT) has been applied AFTER the batteries are connected.

> At this point, the Charging Indicator Light on the test switch should illuminate indicating the battery is charging.

> A short-term discharge test may be conducted after the Emergency Lighting Inverter has been charging for 12 hours.

Charge for 24 hours before conducting a long-term discharge test. Refer to OPERATION for details.

4

STEP #4 WIRING THE EMERGENCY LIGHTING INVERTER’S DIMMING CONNECTIONS (OPTIONAL)

This product features an industry-standard 0-10V dimming voltage output. Existing area dimming controls can be wired

through the product's dimming relay to allow for normal dimming by occupants of the area during Normal mode opera-

tion. The X3 connector accepts wire size # 24 AWG to # 16 AWG. Refer to Illustration 1.

Normal Operation:

AC power is supplied to the AC ballast/AC LED drivers within the connected luminaires through the SW HOT

input. The batteries are charged from power supplied to the UNSW HOT input. Turning on SW-1 on the circuit board supplies

power to the control/monitor circuit and enables the Emergency Lighting Inverter. Dimming control, if used, are passed through

the unit to the connected loads.

Emergency Mode Operation and Dimming:

Immediately after an AC power failure the Emergency Lighting Inverter applies back-up

power to the connected loads and outputs a minimum DC voltage on the 0 – 10V dimming supply. This causes the dimmable

connected loads to start out at minimum light output and consequently, minimum power draw. The ELI-S-250 & ELI-S-185

rapidly increases the 0 – 10V dimming voltage until the output power provided by the inverter reaches the products maximum

emergency mode power into the connected load(s). This is referred to as

Auto-Dimming

. When AC power is restored, the

ELI-S-250 & ELI-S-185 returns to normal charging mode. The ELI-S-250 operates the emergency lighting load for a minimum of

90 minutes. The ELI-S-185 operates the emergency lighting load for a minimum of 120 minutes.

NOTE: Driver efficiency and power factor typically fall as dimming level decreases which must be taken into account when

using the Auto-Dimming feature. This may reduce the maximum AC load connected. Contact the factory with any questions.

Self-Test:

This product contains self-testing functionality. Self-test will automatically perform a 30-second test each month and

a full duration test once per year (90 or 120 minutes, depending on the model). During this automatic test, the product will

perform diagnostics on the battery, the battery charger, the load transfer circuitry, and the load. Any failures will be indicated

by flashing of the charge indicator LED built into the illuminated test switch. This flashing will continue until either the

condition has been corrected and the unit reset OR the next scheduled test has been run successfully.

Load Monitoring / Commissioning:

This product complies with the latest UL standard for emergency lighting, UL 924, and includes

the required load change detection circuit for use when performing the diagnostic self-test routine. When first energized, the

product will automatically perform a 30-second commissioning test to detect the connected emergency lighting load level.

This load level is stored in the product's internal memory. During future tests or outages, the load level will be checked and

compared against this value. If the load level deviates by more than 10%, the product will send an error code through flashing

of the charge indicator LED. The inverter WILL continue to attempt to provide emergency power, regardless of error status.

OPERATION

STEP #6 INSTALLATION OF ENCLOSURE LID

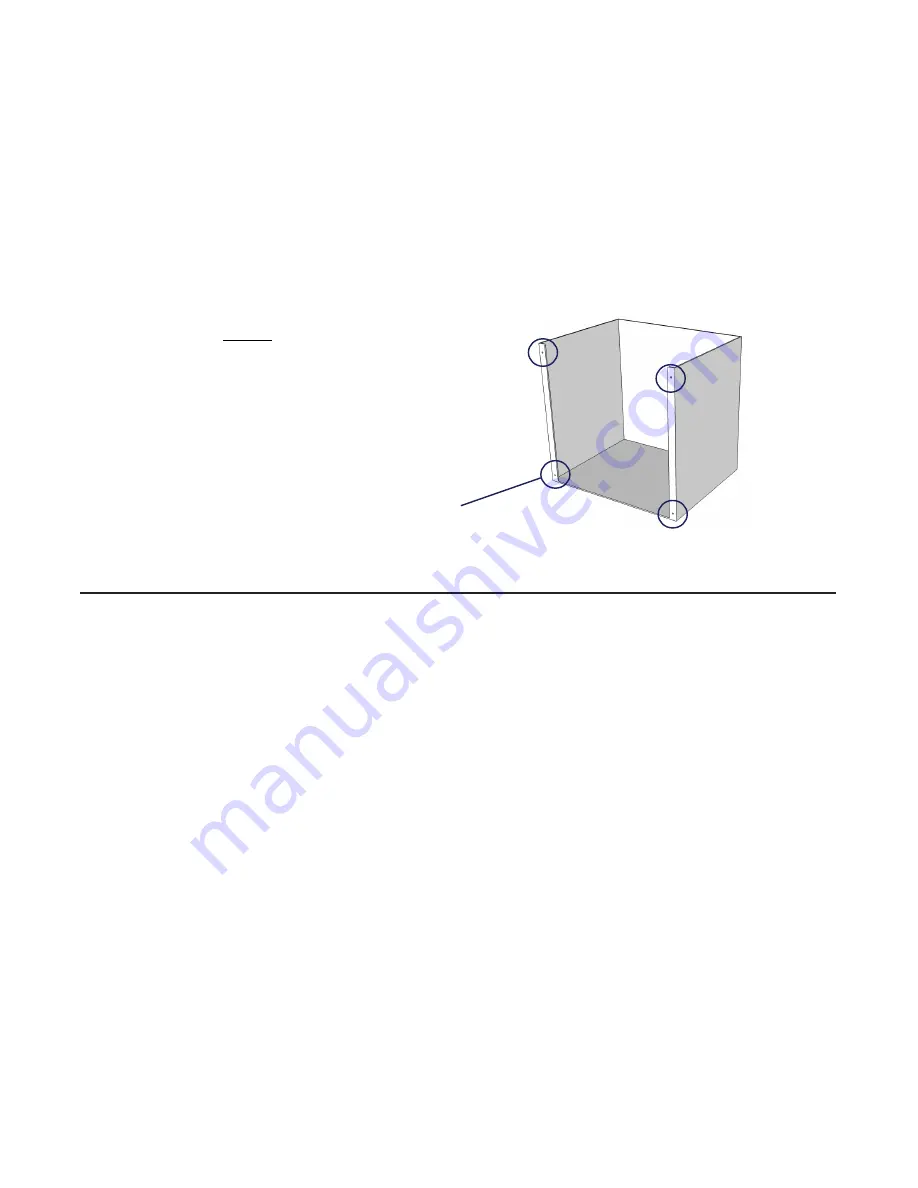

> Remove clip-nuts (X4) from accessory kit.

> Press on to chassis flanges, over lid mounting holes.

> Install the test switch through the hole in the lid.

> Reconnect the test switch to the PCBA.

> Place lid onto unit chassis.

> Install 8-32 screws in lid, through clip nuts(x4).

Clip Locations (x4)